| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

![]()

Introduction:

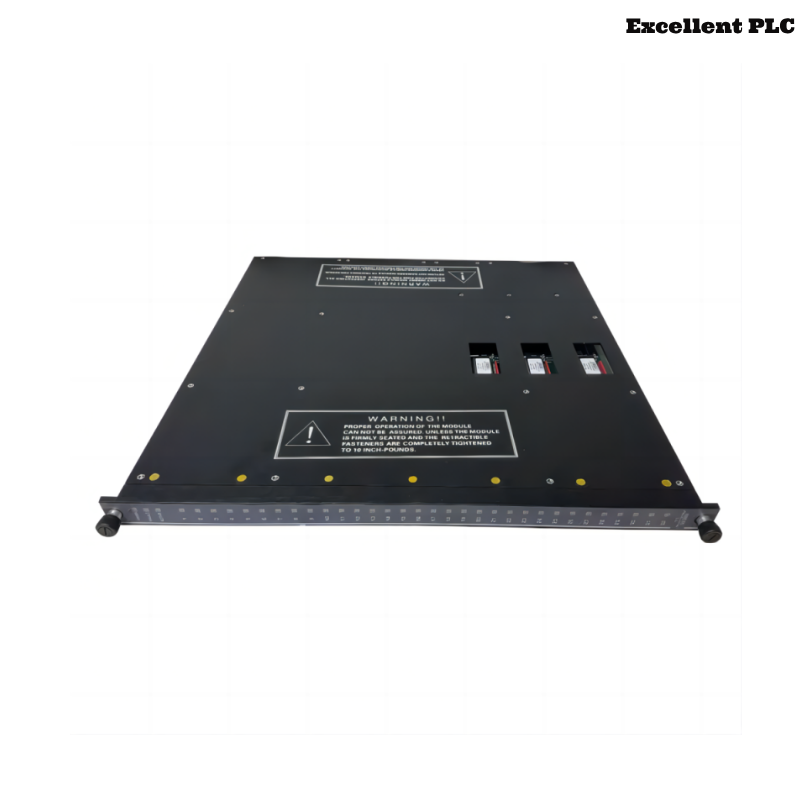

The Triconex 3511 Pulse Input Module is designed for reliable, high-performance digital signal processing in safety-critical applications. This module is part of the Triconex series, known for providing robust and fault-tolerant solutions for industrial process control systems. The 3511 module processes pulse input signals from a wide range of field devices such as flow meters, rotary encoders, and pulse-generating sensors.

With its advanced signal processing capabilities, the Triconex 3511 is particularly effective in applications requiring precise monitoring of pulse-based systems. Whether it’s used in oil and gas, chemical processing, or other industrial automation fields, the 3511 module ensures the integrity and safety of the control system. It provides real-time pulse measurement for critical operations and is part of the Triconex safety instrumented system (SIS), which meets high safety standards.

Specifications:

| Parameter | Details |

|---|---|

| Model | 3511 |

| Number of Channels | 8 Channels |

| Input Type | Pulse Input (TTL compatible) |

| Input Frequency | 0 to 10 kHz |

| Signal Conditioning | Digital Signal Processing |

| Protection Rating | IP20 (Ingress Protection) |

| Mounting Type | DIN Rail |

| Operating Temperature | -20°C to +60°C |

| Dimensions (L x W x H) | 270 x 46 x 253 mm |

| Weight | 3.03 kg |

| Power Supply | 24V DC ± 20% |

| Response Time | 10 ms |

| Connection Type | Spring-type Terminal Blocks |

| Compliance | CE, UL Certified |

Applications:

The Triconex 3511 Pulse Input Module is highly versatile and used in several industrial applications where pulse signals need to be monitored and processed for control purposes. Some of its key applications include:

-

Flow Measurement: In industries such as oil and gas, water treatment, and chemical processing, the 3511 module is used to capture pulse signals from flow meters. It provides accurate flow data to control systems for precise flow control.

-

Machine Monitoring: The module is used in manufacturing settings to monitor the status of machines and equipment by processing pulse signals from rotary encoders or tachometers. It provides real-time feedback to ensure optimal machine performance.

-

Process Control Systems: The 3511 is a crucial component in process control systems where pulse input signals are essential for measuring and controlling parameters like temperature, pressure, and speed.

-

Condition Monitoring: The module helps track equipment health by processing pulse signals from vibration sensors and other monitoring devices. This data is used for predictive maintenance strategies, reducing downtime.

-

Automation Systems: The 3511 module integrates into automation systems where precise pulse signal processing is critical. It ensures that real-time inputs from various sensors are efficiently handled and used in control processes.

Advantages:

-

High Signal Processing Speed: The 3511 module offers fast response times (10ms), making it ideal for high-speed applications that require rapid pulse processing.

-

Compatibility with TTL Signals: The module is compatible with TTL-level pulse inputs, making it highly adaptable to a wide range of field devices such as flow meters, encoders, and sensors.

-

Compact and Robust Design: The compact size (270 x 46 x 253 mm) and durable IP20 protection rating ensure that the module can be easily integrated into existing systems while withstanding typical industrial conditions.

-

Ease of Integration: The 3511 is designed for easy integration into Triconex control systems. It provides seamless communication with other modules and control systems for optimal system performance.

-

Wide Temperature Range: With an operating temperature range from -20°C to +60°C, the module can be used in various industrial environments, ensuring reliable operation across a wide range of conditions.

-

Reliable Power Supply: The module operates on a 24V DC power supply with a ±20% tolerance, making it easy to integrate into existing power systems.

-

Safety Certifications: The module meets international safety standards, including CE and UL certifications, ensuring it is suitable for use in safety-critical applications.

-

Real-time Pulse Processing: The 3511 module processes pulse signals in real-time, providing accurate and immediate data for decision-making in control systems.

-

Reduced Downtime: With its high-performance capabilities, the module minimizes the risk of failure, ensuring continuous monitoring and reducing system downtime.

-

Flexible Connectivity: The spring-type terminal blocks make wiring easier and more secure, while also allowing for simple and error-free connections.

FAQ (Frequently Asked Questions):

-

What is the power supply requirement for the Triconex 3511 module?

The module requires a 24V DC power supply with a tolerance of ±20%. -

How many channels does the Triconex 3511 module support?

The 3511 module supports up to 8 channels for pulse inputs. -

What is the input frequency range of the Triconex 3511?

The module supports input frequencies from 0 to 10 kHz. -

What is the operating temperature range of the module?

The module operates in temperatures from -20°C to +60°C. -

What types of signals can the Triconex 3511 module process?

The module processes TTL-compatible pulse input signals. -

How is the Triconex 3511 module mounted?

The module is designed for DIN rail mounting, making installation straightforward. -

What certifications does the 3511 module have?

The 3511 module is CE and UL certified, meeting international safety and quality standards. -

What is the response time of the 3511 module?

The response time of the module is 10 milliseconds for pulse signal processing. -

What is the protection rating of the Triconex 3511 module?

The module has an IP20 protection rating, suitable for use in dry, indoor environments. -

What is the weight of the Triconex 3511 module?

The weight of the module is 3.03 kg.

Related Models from the Same Series:

| Model | Description | Channels | Input Type | Protection Rating | Response Time | Weight |

|---|---|---|---|---|---|---|

| 3501 | 8-Channel Digital Input Module | 8 | Digital Input | IP20 | 8 ms | 220g |

| 3502 | 16-Channel Digital Input Module | 16 | Digital Input | IP20 | 8 ms | 310g |

| 3510 | 4-Channel Pulse Input Module | 4 | Pulse Input | IP20 | 12 ms | 200g |

| 3520 | 8-Channel Analog Input Module | 8 | Analog Input | IP20 | 15 ms | 250g |

| 3530 | 16-Channel Pulse Input Module | 16 | Pulse Input | IP20 | 10 ms | 350g |

| 3540 | 4-Channel Digital Safety Input Module | 4 | Digital Input | IP20 | 12 ms | 180g |

Popular Triconex Models:

| Model | Description | Channels | Input Type | Protection Rating | Response Time | Weight |

|---|---|---|---|---|---|---|

| 3601 | 8-Channel Digital Safety Input Module | 8 | Digital Input | IP20 | 10 ms | 220g |

| 3701 | 16-Channel Analog Input Module | 16 | Analog Input | IP20 | 15 ms | 330g |

| 3610 | 4-Channel Pulse Input Module | 4 | Pulse Input | IP20 | 12 ms | 200g |

| 3750 | 8-Channel Process Input Module | 8 | Process Input | IP20 | 12 ms | 250g |

| 3810 | 8-Channel Safety Relay Module | 8 | Relay Input | IP20 | 10 ms | 280g |

| 3503 | 16-Channel Pulse Input Module | 16 | Pulse Input | IP20 | 10 ms | 310g |

Excellent PLC

Excellent PLC