| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

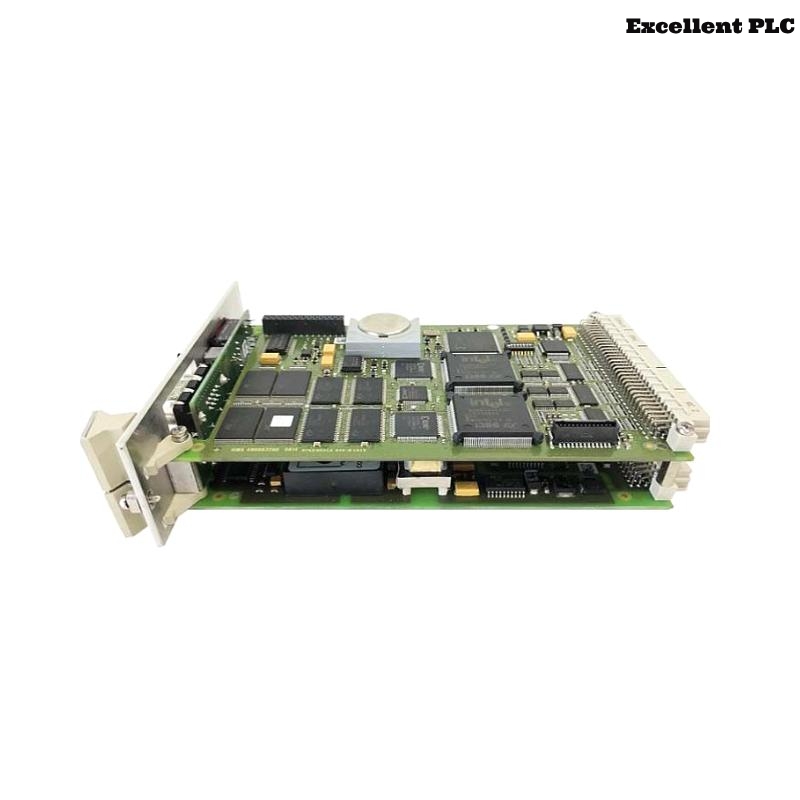

The HIMA F8650A Central Module is a safety-related CPU module designed for use in HIMA’s PES H51q-MS, -HS, and -HRS systems. It is applicable up to Safety Integrity Level 3 (SIL 3) according to IEC 61508 standards. The module features dual clock-synchronized INTEL 386EX microprocessors, each operating at 25 MHz, ensuring high reliability and performance in safety-critical applications.

Technical Specifications

| Parameter | Specification |

| Model Number | F8650A |

| Microprocessors | 2 × INTEL 386EX, 32-bit, 25 MHz |

| Memory per Processor | 1 MB Flash-EPROM (OS), 1 MB SRAM (Data) |

| Interfaces | 2 × RS-485 serial interfaces with electrical isolation |

| Diagnostic Display | 4-digit matrix display with selectable information |

| Fault Shutdown | Safety-related watchdog with 24 V output, loadable up to 500 mA, short-circuit proof |

| Construction | Two European standard PCBs, one PCB for diagnostic display |

| Space Requirement | 8 SU (Standard Units) |

| Power Supply | 5 V / 2 A |

| Operating Temperature | -40°C to +70°C |

| Dimensions (W × H × D) | 257 x 114 x 30 mm |

| Weight | 1.5 kg |

| Country of Origin | Germany |

Applications

The HIMA F8650A Central Module is utilized in various safety-critical industrial applications, including:

-

Process Control Systems: Managing and monitoring industrial processes in chemical, petrochemical, and pharmaceutical industries.

-

Power Generation: Ensuring safe operation of turbines, generators, and associated control systems.

-

Oil and Gas: Monitoring and controlling safety functions in offshore and onshore facilities.

-

Transportation Systems: Implementing safety measures in railway and metro control systems.

-

Manufacturing Automation: Providing safety control in automated production lines and machinery.

Advantages

-

High Reliability: Dual redundant processors ensure continuous operation even in the event of a processor failure.

-

Safety Compliance: Certified up to SIL 3, meeting stringent safety requirements.

-

Versatile Communication: Supports multiple fieldbus protocols, including PROFIBUS PA, Foundation Fieldbus, and HART.

-

Robust Design: Operates reliably in extreme temperatures and harsh industrial environments.

-

Comprehensive Diagnostics: Built-in diagnostic display provides real-time status and error information.

Latest News Titles

-

HIMA F8650A Central Module Enhances Safety in Industrial Automation

-

Advancements in SIL 3 Certified Control Systems with HIMA F8650A

-

Integrating HIMA F8650A into Modern Process Control Architectures

-

Ensuring Operational Safety: The Role of HIMA F8650A in Power Plants

-

HIMA’s Commitment to Safety: Spotlight on the F8650A Central Module

-

Fieldbus Communication Simplified with HIMA F8650A Module

-

HIMA F8650A: A Reliable Solution for Safety-Critical Applications

-

Optimizing Industrial Safety Systems with HIMA’s F8650A Module

-

HIMA F8650A Central Module: Bridging Safety and Performance

-

Implementing Redundant Safety Systems Using HIMA F8650A

Frequently Asked Questions (FAQs)

-

What is the primary function of the HIMA F8650A Central Module?

-

It serves as the central processing unit in HIMA’s safety systems, managing safety-related control functions.

-

-

Which systems are compatible with the F8650A module?

-

It is designed for use in PES H51q-MS, -HS, and -HRS systems.

-

-

What safety standards does the F8650A comply with?

-

It is certified up to SIL 3 according to IEC 61508.

-

-

What type of processors does the F8650A use?

-

It utilizes two INTEL 386EX 32-bit microprocessors, each operating at 25 MHz.

-

-

What are the memory specifications of the F8650A?

-

Each processor has 1 MB Flash-EPROM for the operating system and 1 MB SRAM for data storage.

-

-

What communication interfaces are available on the F8650A?

-

It features two RS-485 serial interfaces with electrical isolation.

-

-

Does the F8650A have diagnostic capabilities?

-

Yes, it includes a 4-digit matrix display for real-time diagnostics and status information.

-

-

What are the power requirements for the F8650A?

-

It operates on a 5 V power supply with a current draw of 2 A.

-

-

What is the operating temperature range of the F8650A?

-

It functions reliably within a temperature range of -40°C to +70°C.

-

-

What are the dimensions and weight of the F8650A module?

-

The module measures 257 x 114 x 30 mm and weighs 1.5 kg.

-

Related Models (Same Series or Functionally Similar to HIMA F8650A)

| Model Number | Description | Features Summary |

| F8650 | Central Module for H51q systems | Standard version of central control with SIL 3 compliance |

| F8650E | Extended Central Module | Enhanced memory and communication ports |

| F8652 | Central Module with additional redundancy | SIL 3 capable, higher fault-tolerance |

| F8607 | CPU/Control Module for safety systems | Compact and cost-effective, suitable for smaller systems |

| F8653 | Advanced CPU Module for larger installations | Offers extended diagnostics and remote update features |

| F8651 | High-performance Safety CPU Module | Focused on high-frequency process applications |

| F8654 | Safety Central Processor Module | Enhanced data logging and remote interfacing |

| F8601 | Safety-Related Logic Processor Module | Modular CPU for distributed safety architecture |

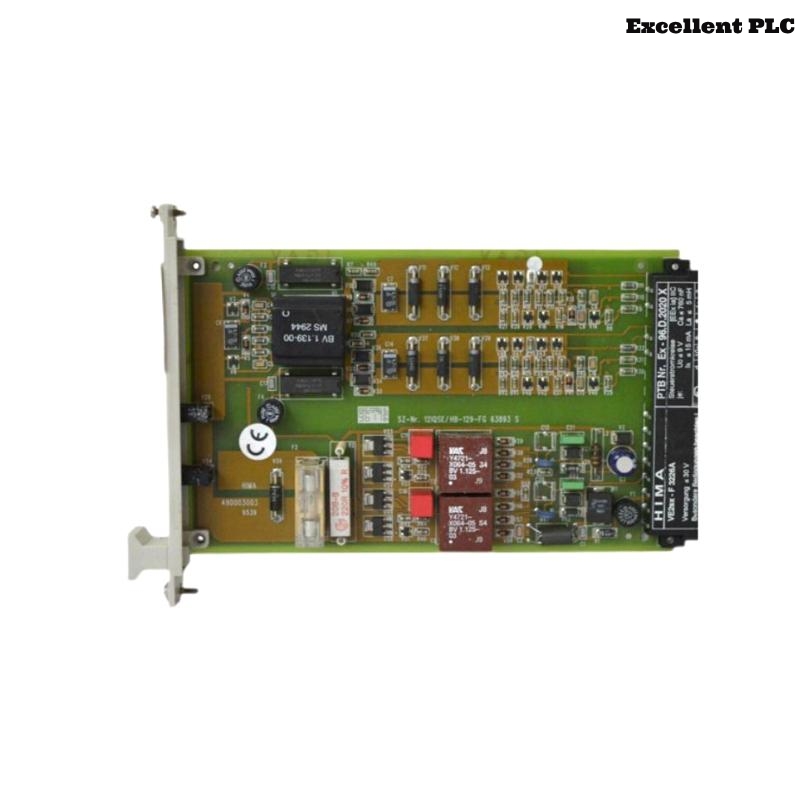

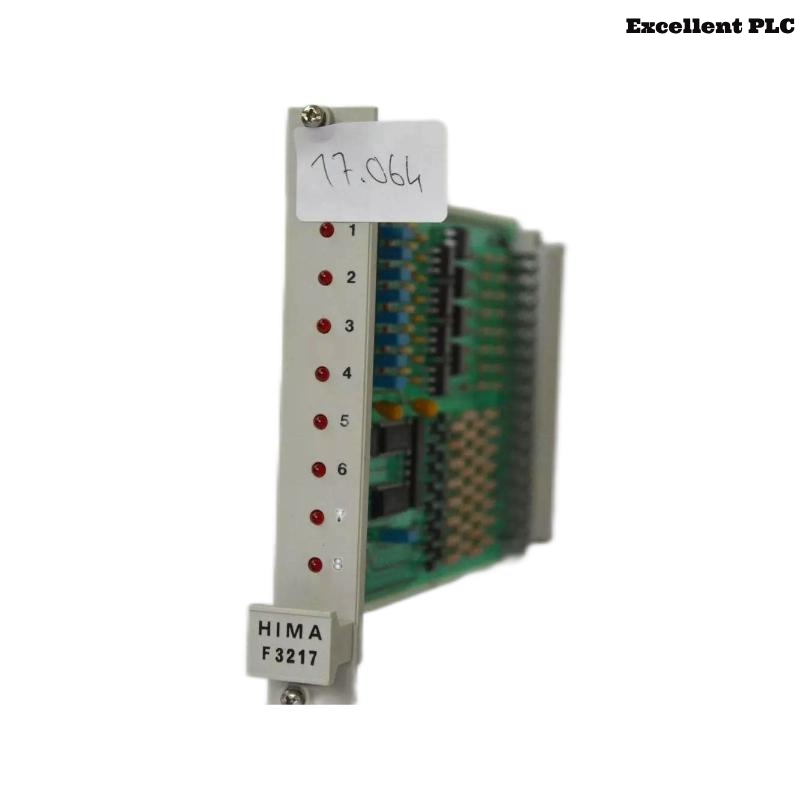

Popular HIMA Models (Same Brand – HIMA)

| Model Number | Description | Application Focus |

| F7133 | Digital Output Module (Relay) | Discrete output switching in safety systems |

| F6208 | Power Supply Module | Reliable power for system components |

| F8621A | CPU/Logic Module with Fieldbus Interface | High-speed safety logic and fieldbus support |

| F3423 | Digital Input Module | Secure input acquisition from field devices |

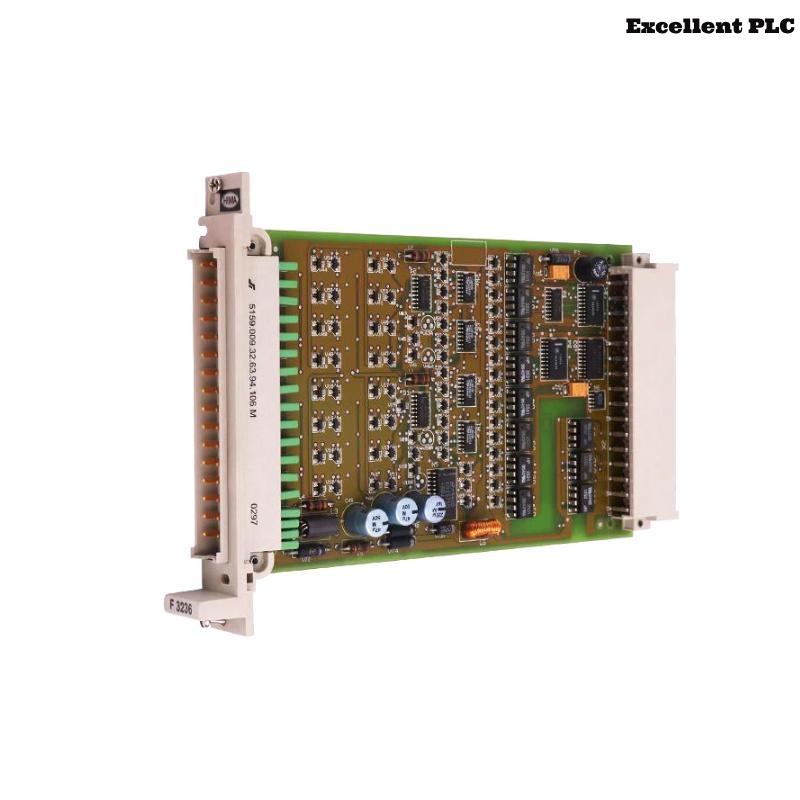

| F3236 | Analog Output Module | Precise analog signal control |

| F8650A | Central Safety Control Module | Main CPU for safety-critical applications |

| F7126 | Digital Output Module (24 VDC) | Used in ESD and fire/gas systems |

| F7130 | Relay Output Module (Isolated) | High-isolation control of external actuators |

Excellent PLC

Excellent PLC