| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction:

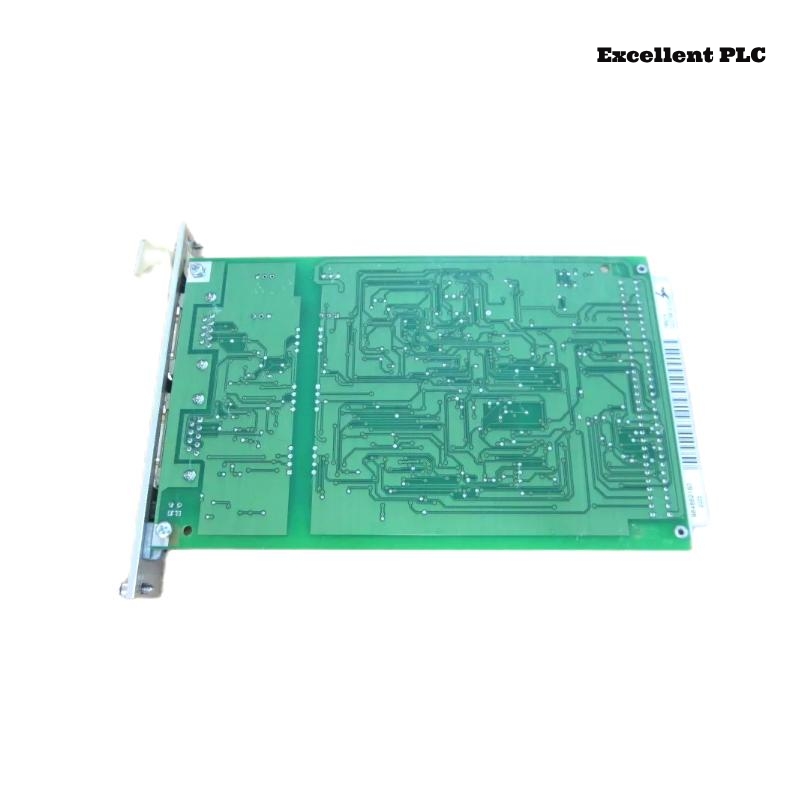

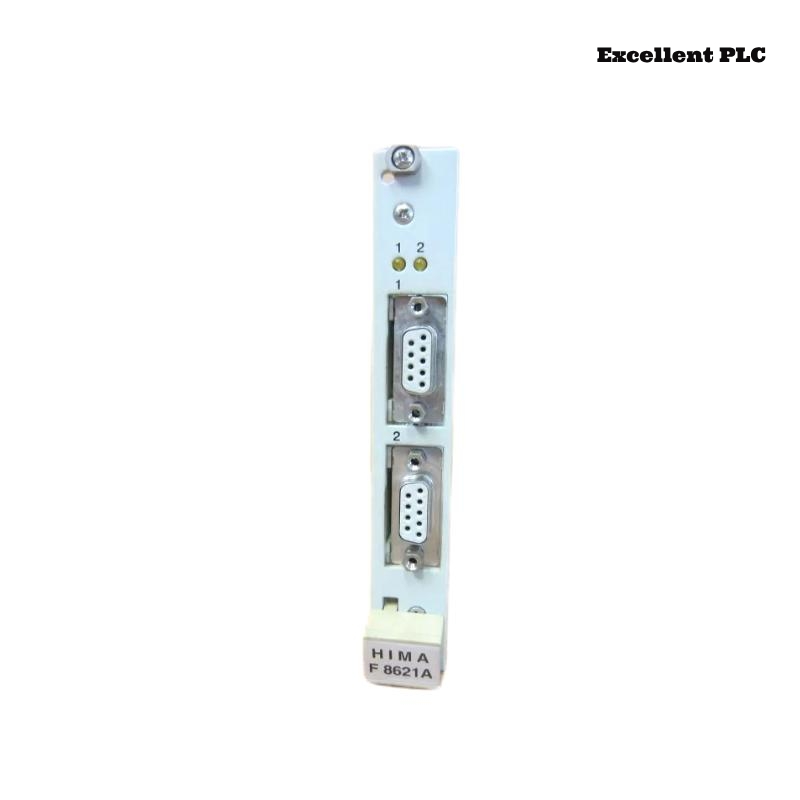

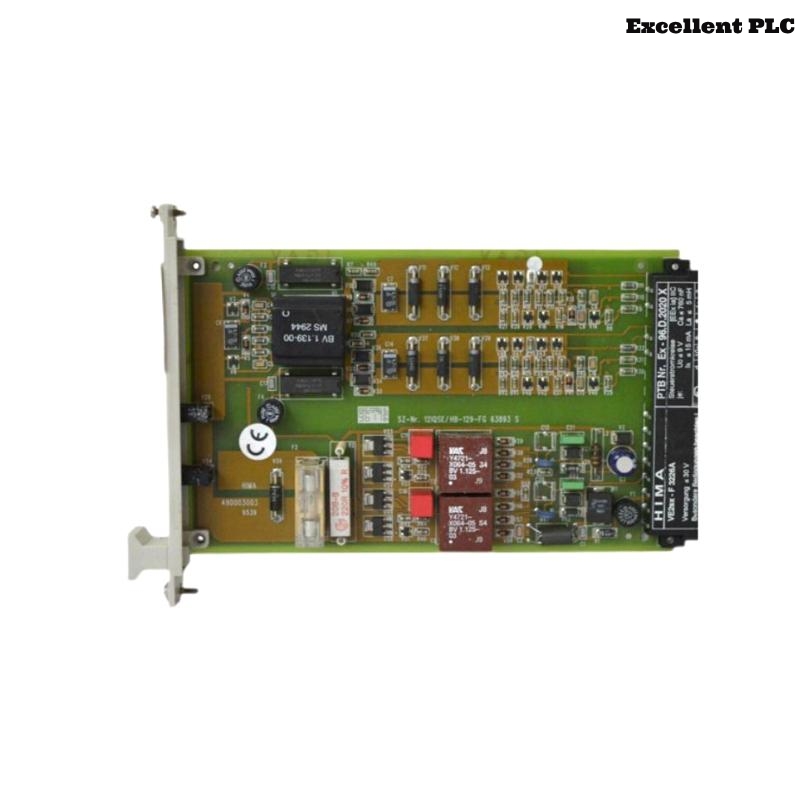

The HIMA F8621A CPU Module is a key component of HIMA’s safety and control systems. It is designed to provide high-performance computing for industrial automation systems, ensuring secure and reliable operations in a variety of critical applications. This CPU module is widely used in safety-critical industries where fault tolerance, redundancy, and scalability are essential. With advanced features for diagnostic capabilities, high-speed processing, and seamless integration, the F8621A is built to handle demanding automation tasks and maintain the highest safety standards.

Product Specifications:

| Specification | Details |

|---|---|

| Model | HIMA F8621A CPU Module |

| Processor Type | Multi-core processor |

| Operating System | Real-time operating system (RTOS) |

| Communication Protocol | Ethernet, Modbus, Profibus, CAN |

| Power Supply | 24 VDC, Power Consumption: 30W |

| Input/Output Capacity | 8 Digital Inputs, 8 Digital Outputs |

| Dimensions (L x W x H) | 200 x 100 x 50 mm |

| Weight | 1.2 kg |

| Environmental Protection | IP20 (Protection against dust) |

| Operating Temperature | -20°C to 60°C |

| Redundancy | Hot-swap capability for redundancy |

| Certification | IEC 61508, SIL 3 |

Applications:

The HIMA F8621A CPU Module is designed for a wide range of industrial applications that require safety, reliability, and performance, including:

-

Process Automation: Used in chemical plants, oil refineries, and pharmaceutical industries for controlling hazardous processes.

-

Energy Generation: Ensures safe operation in power plants, including nuclear, gas, and wind power generation.

-

Critical Infrastructure: Applied in transportation systems, water treatment facilities, and security systems for safety-critical control.

-

Manufacturing: Used in automotive, electronics, and heavy machinery industries to ensure automated processes meet strict safety requirements.

-

Automation in High-Risk Environments: Ideal for applications where process interruption could result in hazardous situations, such as in oil & gas extraction or chemical processing.

Advantages:

-

High Safety Standards: Meets the highest safety requirements with compliance to IEC 61508 and SIL 3 certifications.

-

Modular & Scalable: Designed to scale for complex systems, allowing easy integration with additional modules and devices.

-

Robust Performance: High-speed processor ensures rapid response times even in complex, high-demand scenarios.

-

Redundancy & Fault Tolerance: Offers built-in redundancy features for fault tolerance, increasing system reliability and uptime.

-

Flexible Communication: Supports multiple industrial protocols, enabling seamless integration with different control systems.

-

Durability: Capable of operating in harsh environmental conditions (temperature range from -20°C to 60°C).

-

Easy Integration: Simple to integrate with existing systems due to compatibility with standard industrial networks.

Latest News:

-

“HIMA’s F8621A CPU Module Enhances Safety for Oil and Gas Industry”: HIMA’s innovative CPU technology is now being used to improve operational safety and reduce downtime in critical oil and gas platforms.

-

“F8621A Module Certified for SIL 3 – Setting New Standards in Industrial Automation”: The F8621A module’s latest certification ensures it meets the highest standards for industrial safety, providing peace of mind for high-risk industries.

-

“HIMA F8621A CPU Enhances Redundancy and Fault Tolerance in Power Plants”: The new CPU module from HIMA is now delivering advanced redundancy capabilities for continuous and safe power generation.

FAQ:

-

What is the HIMA F8621A CPU Module used for?

-

It is used in safety-critical industrial applications, ensuring reliable operation and compliance with the highest safety standards.

-

-

What industries benefit from using the F8621A CPU Module?

-

Industries such as process automation, energy generation, manufacturing, and critical infrastructure applications benefit from its capabilities.

-

-

What safety certifications does the F8621A have?

-

It is certified according to IEC 61508, achieving SIL 3 (Safety Integrity Level 3) certification for industrial safety.

-

-

What are the communication protocols supported by the F8621A CPU?

-

The module supports protocols including Ethernet, Modbus, Profibus, and CAN for flexible system integration.

-

-

What is the operating temperature range of the F8621A?

-

The module operates in temperatures ranging from -20°C to 60°C, suitable for various industrial environments.

-

-

Can the F8621A be integrated with existing systems?

-

Yes, it is designed for easy integration with existing control systems, providing flexibility in complex environments.

-

-

Does the F8621A offer redundancy features?

-

Yes, the F8621A supports hot-swappable redundancy for fault tolerance and system reliability.

-

-

What power supply is required for the F8621A CPU?

-

The module operates on a 24 VDC power supply, with a power consumption of 30W.

-

-

What is the weight of the F8621A CPU Module?

-

The module weighs 1.2 kg.

-

-

What are the dimensions of the F8621A CPU Module?

-

The dimensions are 200 x 100 x 50 mm.

-

Recommended Models

Related Models from the F8600 Series

| Model | Description | Key Features |

|---|---|---|

| HIMA F8600A | Basic CPU module for industrial automation. | High-performance, scalable, SIL 2, modular design. |

| HIMA F8610A | Advanced controller for critical infrastructure. | SIL 3 certified, redundant, integrated diagnostics. |

| HIMA F8630A | High-speed controller with increased I/O capacity. | Enhanced I/O, real-time data processing. |

| HIMA F8640A | CPU for high-risk process control systems. | Dual processors, fault tolerance, robust communication. |

| HIMA F8650A | High-performance CPU for process automation. | Hot-swap, high redundancy, temperature range -40°C to 70°C. |

| HIMA F8660A | Safety and control module for advanced systems. | Supports up to 1,000 I/O, real-time performance. |

| HIMA F8670A | Modular system controller for large-scale automation. | SIL 3, scalable, integrates with multiple networks. |

| HIMA F8680A | Compact CPU for small industrial applications. | Low power consumption, compact design, modular. |

Popular Models from HIMA

| Model | Description | Key Features |

|---|---|---|

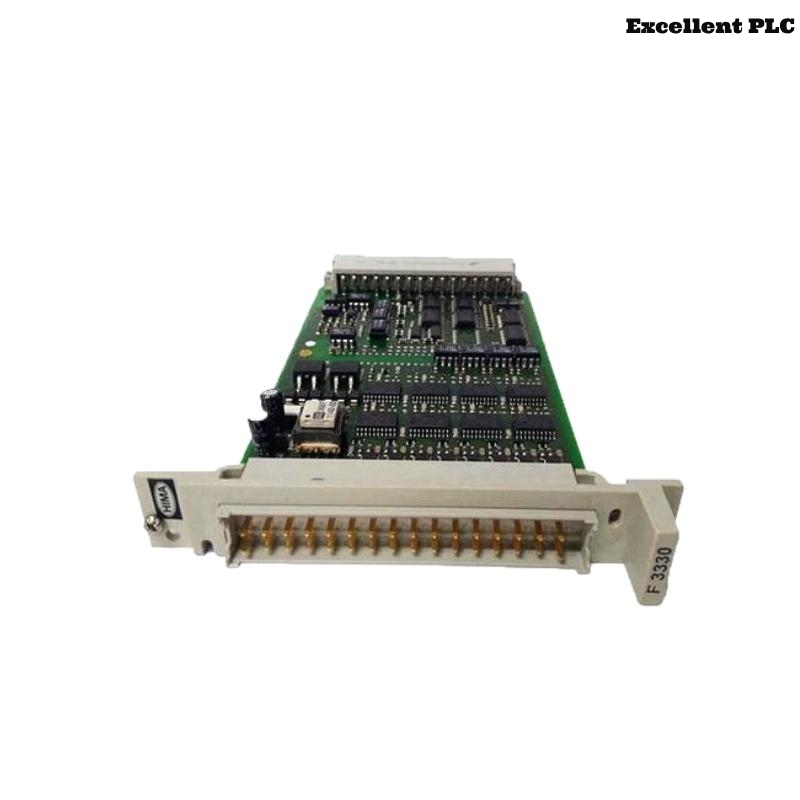

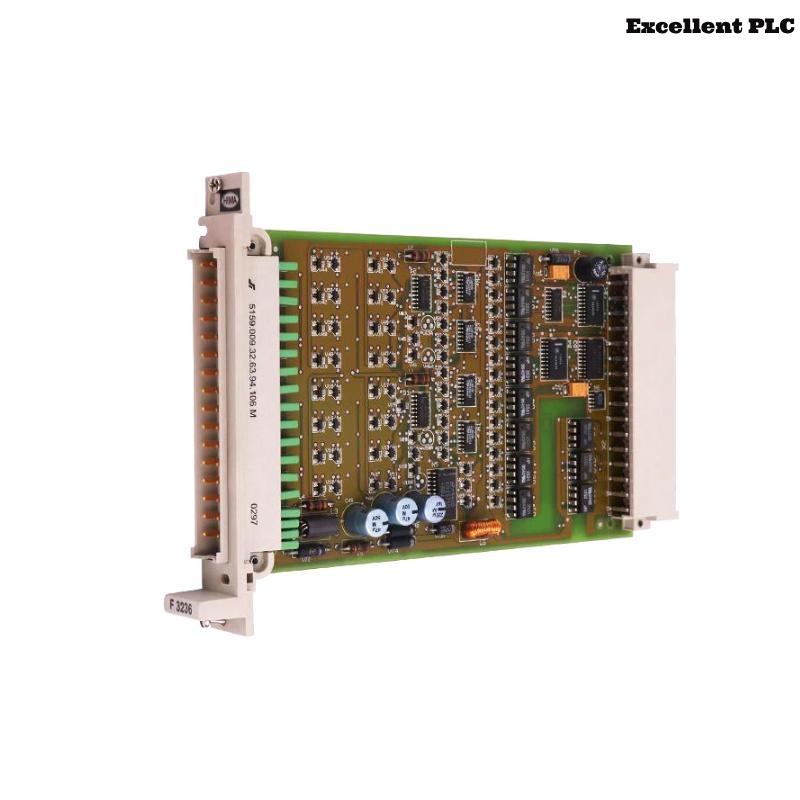

| HIMA F3230 | Control module for safety systems. | SIL 3 certified, suitable for chemical and energy sectors. |

| HIMA F3320 | Process safety controller for oil and gas. | High fault tolerance, hot-standby capabilities. |

| HIMA F7120 | Compact, integrated safety and control system. | Modular, flexible, suitable for industrial plants. |

| HIMA F7210 | Safety controller with advanced diagnostics. | Real-time monitoring, high availability. |

| HIMA F2110 | Modular control system for complex automation. | Scalable, supports diverse communication protocols. |

| HIMA F2300 | Intelligent safety controller for process control. | Easy integration, redundancy, fault detection. |

| HIMA F6120 | Safety and control solution for critical environments. | Designed for high-risk industries, fault-tolerant. |

| HIMA F6220 | Advanced controller with modular design. | Scalable, supports SIL 2 & SIL 3 standards. |

Excellent PLC

Excellent PLC