| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Introduction

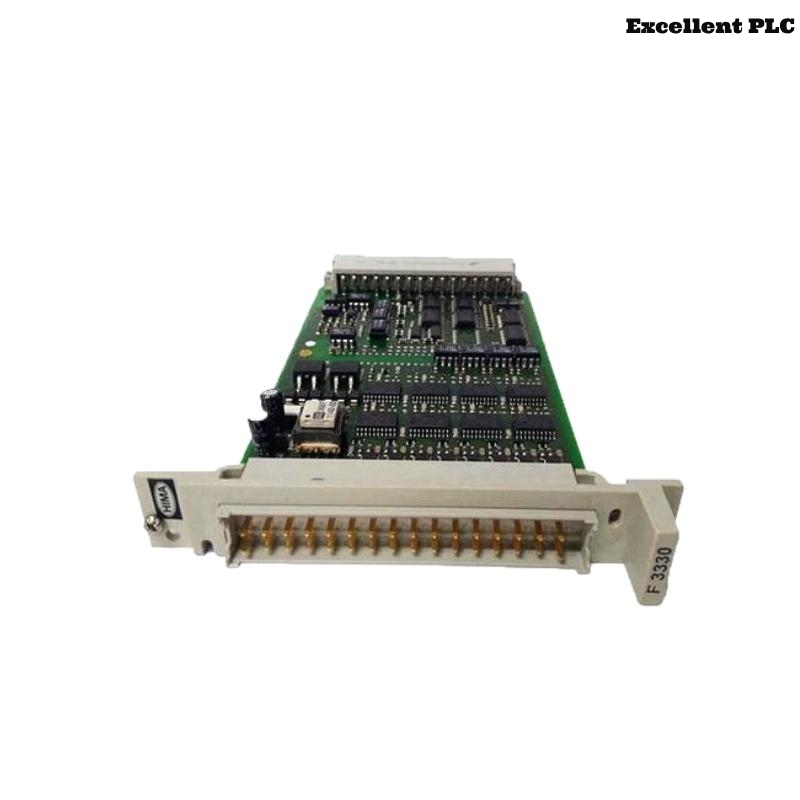

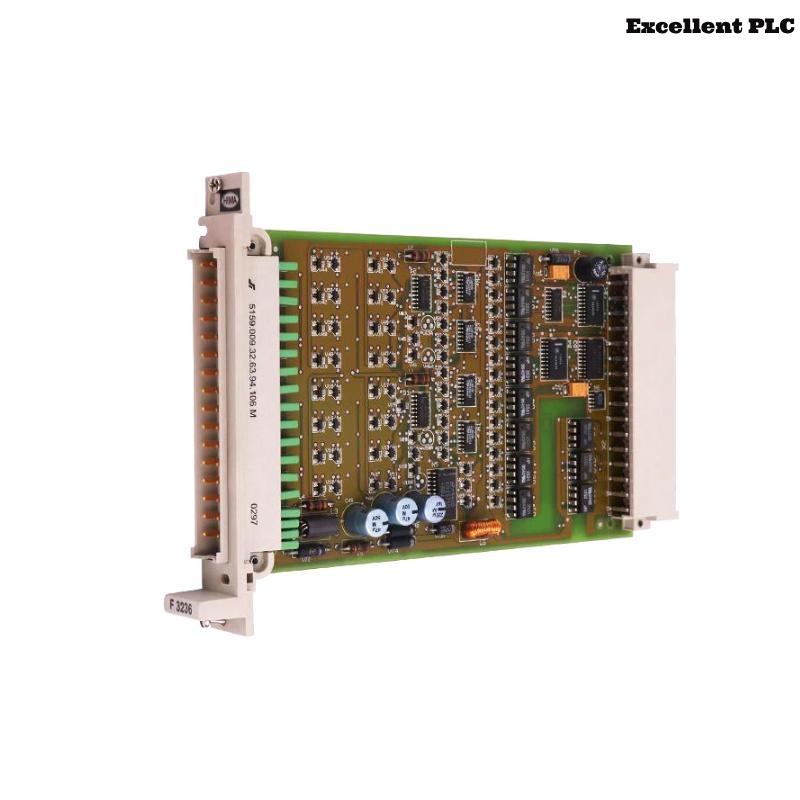

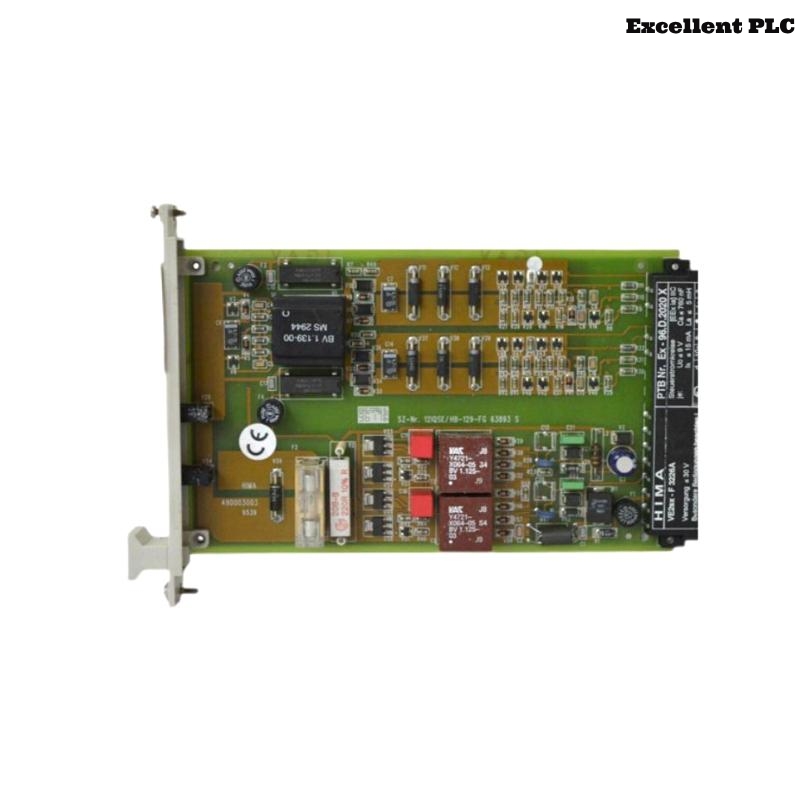

The HIMA F6220 Thermocouple Input Module is a high-precision module designed for industrial temperature measurement applications. As part of HIMA’s renowned safety and automation solutions, the F6220 provides reliable thermocouple signal processing for critical temperature monitoring in industries such as oil & gas, power generation, chemical processing, and manufacturing.

Equipped with multiple thermocouple input channels, this module supports various thermocouple types and ensures accurate temperature readings with high immunity to electrical noise. Designed for seamless integration into HIMA’s safety and control systems, the F6220 is ideal for applications where temperature stability and precision are paramount.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | HIMA F6220 |

| Module Type | Thermocouple Input Module |

| Input Channels | Multiple (typically 8-16) |

| Supported Thermocouples | Type K, J, T, E, N, R, S, B |

| Input Signal Range | -100°C to +1300°C (depends on type) |

| Measurement Accuracy | ±0.1% of full-scale value |

| Cold Junction Compensation | Yes, automatic |

| Isolation | Galvanic isolation for each channel |

| Power Supply | 24V DC |

| Response Time | <100ms |

| Communication Interface | HIMA safety system bus |

| Operating Temperature | -20°C to +70°C |

| Humidity Tolerance | 5% – 95% non-condensing |

| Protection Class | IP20 |

| Compliance Standards | IEC 61508, SIL 3 certified |

| Dimensions | 100 x 25 x 120 mm |

| Weight | 0.25 kg |

Applications

The HIMA F6220 module is widely used in various industries for precise and safe temperature monitoring, including:

-

Oil & Gas: Monitoring temperature in pipelines, refining processes, and offshore platforms.

-

Power Generation: Ensuring safe temperature control in turbines, boilers, and heat exchangers.

-

Chemical Processing: Maintaining optimal conditions in reactors and distillation units.

-

Pharmaceutical Manufacturing: Monitoring temperature-sensitive production processes.

-

Metallurgy & Steel Industry: Measuring high-temperature furnace operations.

-

Food & Beverage: Ensuring safe cooking and processing temperatures in industrial kitchens.

Advantages

-

High Precision: Supports multiple thermocouple types with ±0.1% accuracy.

-

Wide Temperature Range: Capable of measuring extreme temperatures from -100°C to +1300°C.

-

Industrial-Grade Durability: Built to withstand harsh environments and electrical noise.

-

Automatic Cold Junction Compensation: Enhances measurement accuracy in fluctuating conditions.

-

SIL 3 Certified: Meets stringent safety requirements for critical processes.

-

Fast Response Time: Less than 100ms for real-time temperature monitoring.

-

Reliable Isolation: Galvanic isolation for each input prevents interference and ensures signal integrity.

-

Easy Integration: Seamlessly connects to HIMA control systems for efficient process automation.

Latest News Titles

-

“HIMA F6220: Revolutionizing Industrial Temperature Monitoring”

-

“SIL 3 Certified Thermocouple Input Modules: Why HIMA Leads the Market”

-

“Enhancing Process Safety with HIMA’s Advanced F6220 Module”

-

“How HIMA F6220 Ensures Accuracy in High-Risk Temperature Applications”

-

“Comparing Thermocouple Input Modules: What Makes HIMA F6220 Stand Out?”

-

“New Innovations in Industrial Safety: The Role of HIMA F6220”

-

“Case Study: HIMA F6220 in High-Temperature Steel Manufacturing”

-

“Understanding the Role of Thermocouple Input Modules in Process Automation”

-

“Improving Efficiency in Oil & Gas with HIMA F6220”

-

“Temperature Control in Power Plants: The Benefits of HIMA’s F6220”

Frequently Asked Questions (FAQ)

-

What thermocouple types does the HIMA F6220 support?

It supports Type K, J, T, E, N, R, S, and B thermocouples. -

What is the maximum temperature the module can measure?

It depends on the thermocouple type, but the maximum range is up to +1300°C. -

Is the module suitable for safety-critical applications?

Yes, it is SIL 3 certified according to IEC 61508 safety standards. -

Can this module be integrated with other HIMA systems?

Yes, it is designed to work seamlessly with HIMA safety and automation systems. -

Does it provide cold junction compensation?

Yes, it features automatic cold junction compensation for enhanced accuracy. -

What is the response time of the F6220 module?

It has a response time of less than 100ms. -

Is the module resistant to electrical noise?

Yes, it has galvanic isolation for each input channel to prevent interference. -

What is the operating temperature range of this module?

It operates between -20°C and +70°C. -

Can it be used in humid environments?

Yes, it has a humidity tolerance of 5% – 95% (non-condensing). -

What industries commonly use the HIMA F6220?

It is widely used in power generation, oil & gas, chemical processing, metallurgy, and pharmaceuticals.

Recommended Related Models

| Model | Input Type | No. of Channels | SIL Certification |

|---|---|---|---|

| HIMA F6217 | Analog Input | 8 | SIL 3 |

| HIMA F6219 | Resistance Temperature Detector (RTD) | 16 | SIL 3 |

| HIMA F6221 | Voltage Input Module | 8 | SIL 3 |

| HIMA F6222 | Current Input Module | 8 | SIL 3 |

| HIMA F7126 | Thermocouple Input | 16 | SIL 3 |

| HIMA F7131 | Temperature Transmitter Input | 8 | SIL 3 |

| HIMA F8642 | High-Speed Analog Input | 4 | SIL 3 |

| HIMA F8650E | Multi-Function Input | 12 | SIL 3 |

Popular Models from the Same Brand

| Model | Application | Input Type | SIL Certification |

|---|---|---|---|

| HIMA HIMax | Safety PLC | Multiple | SIL 3 |

| HIMA HIMatrix | Compact Safety Controller | Digital/Analog | SIL 3 |

| HIMA F3331 | Digital Output Module | Digital | SIL 3 |

| HIMA F8627X | Communication Module | Ethernet | SIL 3 |

| HIMA F8652X | Power Supply Module | Ethernet | SIL 3 |

| HIMA F7105 | Relay Output Module | Relay | SIL 3 |

| HIMA F7553 | High-Speed Counter | Pulse Input | SIL 3 |

| HIMA F8621A | CPU Module | Ethernet | SIL 3 |

Excellent PLC

Excellent PLC