| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

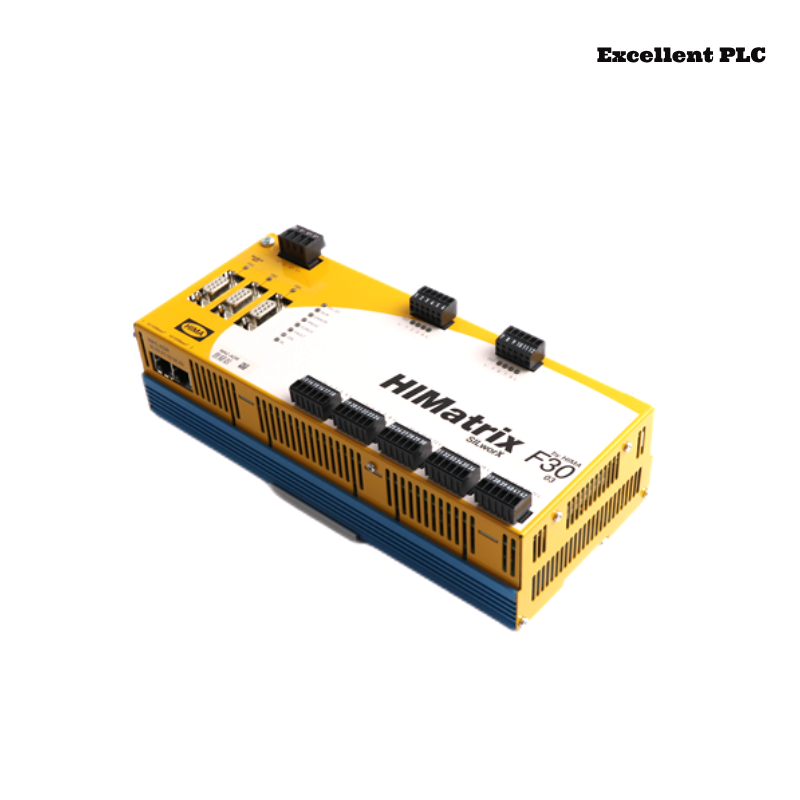

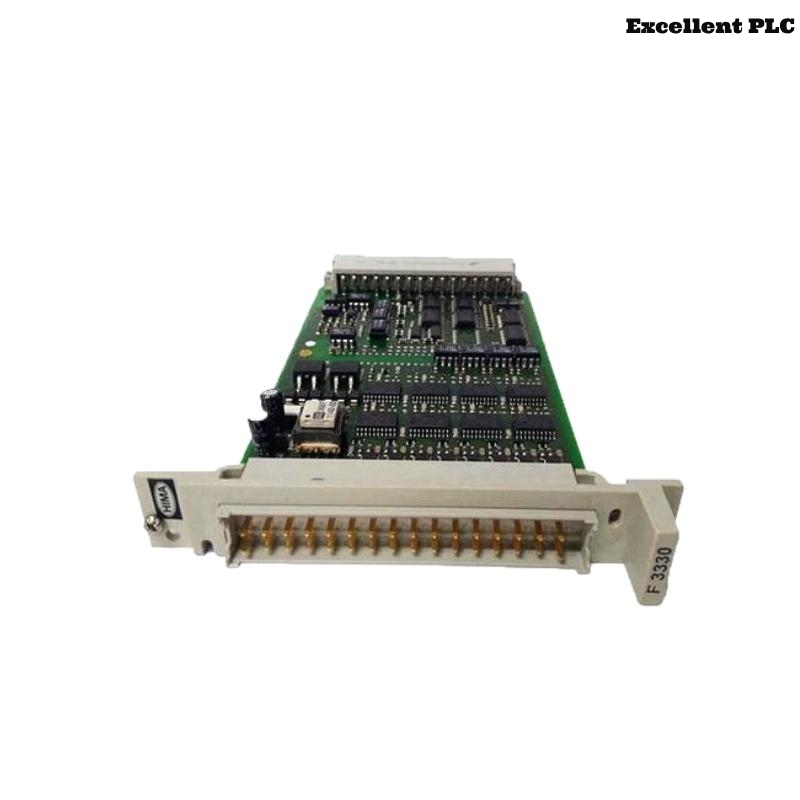

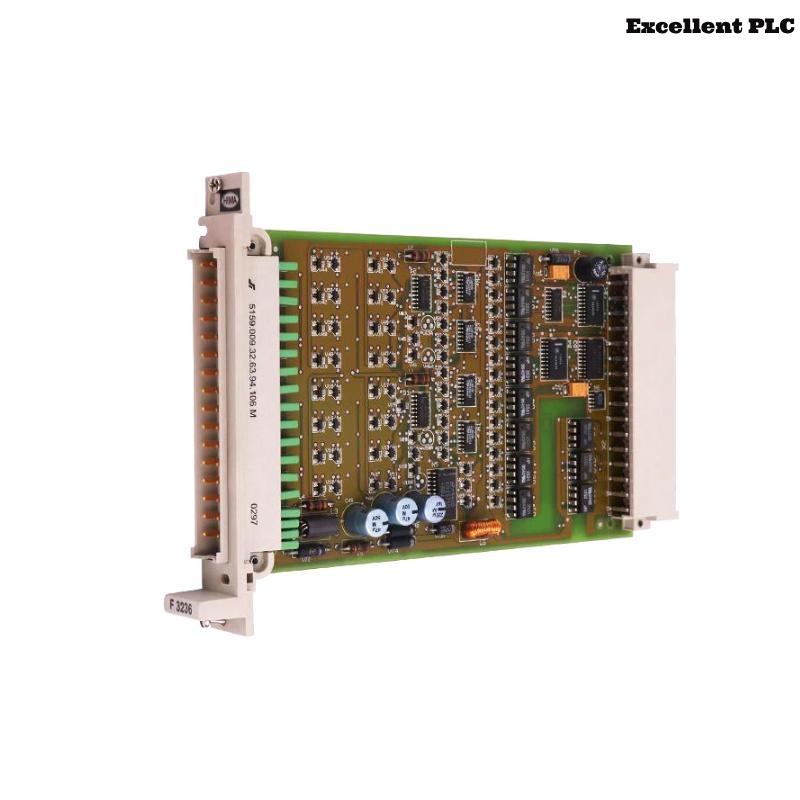

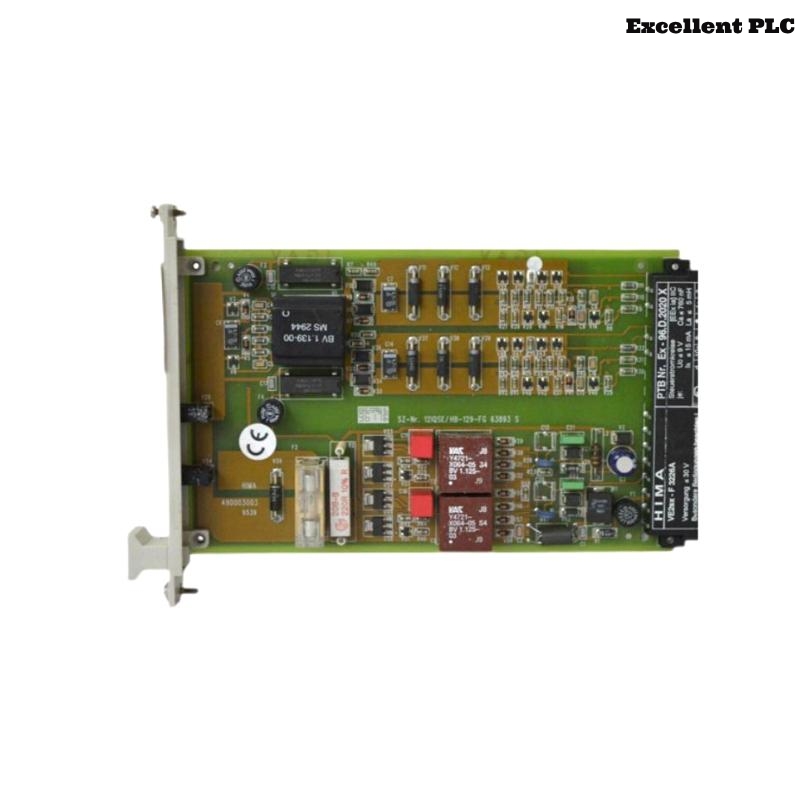

The HIMA F3003 Safety-Related Controller is a key component of the HIMA safety system family, designed to provide high-performance safety control in critical industrial applications. Specifically engineered for use in process control, automation, and safety-critical environments, the F3003 controller ensures the safety, reliability, and performance of complex industrial systems. It is designed to meet the highest standards of functional safety, providing a robust solution for applications where safety and uptime are paramount.

The HIMA F3003 is widely used in industries such as oil and gas, chemical processing, power generation, and manufacturing, where safety and regulatory compliance are critical. The controller supports the implementation of safety instrumented systems (SIS), emergency shutdown systems (ESD), and other safety-related processes that prevent hazardous events and ensure compliance with international safety standards such as IEC 61508 and IEC 61511.

Product Specifications

| Specification | Details |

|---|---|

| Model | HIMA F3003 Safety-Related Controller |

| Type | Safety-related Controller |

| Input Types | Digital, Analog, and Fieldbus Inputs |

| Outputs | Digital Outputs, Analog Outputs, and Relay Outputs |

| Communication Interfaces | PROFIBUS DP, Modbus, HART, and other fieldbus protocols |

| Safety Integrity Level (SIL) | SIL 3 (according to IEC 61508 and IEC 61511) |

| Power Supply | 24 V DC (Nominal), 18 V DC to 30 V DC |

| Temperature Range | -20°C to +60°C |

| Dimensions (L x W x H) | 257 x 114 x 66 mm |

| Weight | 1.2 kg |

| Housing Type | Metal housing, IP20 rated |

| Mounting | DIN Rail Mount |

| Certification | CE, UL, ATEX (for hazardous areas) |

| Diagnostics | Advanced diagnostic capabilities with real-time feedback |

| Redundancy | Redundant power supply and CPU (Hot Standby) |

| Certification | IEC 61508, IEC 61511, SIL 3 certified |

| Environmental Protection | Protection class IP20 |

Applications

The HIMA F3003 Safety-Related Controller is designed for a wide range of critical applications, where safety is a top priority. These applications include:

- Oil and Gas: The F3003 is widely used in offshore and onshore facilities, particularly in emergency shutdown systems (ESD) to protect against process upsets, fires, or explosions.

- Chemical Processing: It is implemented in chemical plants for managing safety processes, ensuring protection against toxic leaks or dangerous reactions.

- Power Generation: The F3003 ensures safe and reliable operation of critical processes in power plants, including boiler protection, turbine monitoring, and reactor safety.

- Nuclear Power Plants: The F3003 controller is used for safety-critical systems that ensure the safe operation of nuclear reactors, adhering to strict safety standards.

- Manufacturing: In factories with automated production lines, the F3003 helps control and monitor safety systems to prevent accidents and ensure smooth operation.

- Pharmaceutical: Applied in pharmaceutical production lines to maintain the integrity of manufacturing processes and comply with strict safety standards.

- Food & Beverage: Used to manage safety and quality control in food and beverage production, ensuring a safe environment for both workers and consumers.

- Water Treatment: The controller plays an integral role in water treatment plants, helping to monitor and control safety-critical processes like chemical dosing and water quality management.

- Mining: In mining operations, the F3003 is used to monitor hazardous processes and protect against accidents in high-risk environments.

- Automotive Manufacturing: Applied in automotive production lines to ensure that all safety protocols are met, preventing accidents during the manufacturing process.

Advantages

- High Safety Integrity: The F3003 meets SIL 3 safety requirements as per IEC 61508, providing the highest level of safety for industrial applications.

- Redundancy and Availability: With hot standby functionality for CPUs and power supplies, the F3003 ensures high availability, reducing downtime and increasing system reliability.

- Versatile Input/Output Options: The controller supports a wide range of input and output types (digital, analog, relay), making it suitable for diverse industrial applications.

- Flexible Communication: The F3003 supports several fieldbus protocols, including PROFIBUS DP, Modbus, and HART, allowing easy integration with existing systems.

- Diagnostic Features: With advanced diagnostic capabilities, the F3003 helps detect and troubleshoot faults before they result in system failures, improving uptime and system health.

- Scalable and Modular: The modular architecture of the F3003 allows for scalable solutions, making it easy to expand the system as operational requirements grow.

- Compliance with International Standards: The F3003 meets international safety standards, including IEC 61508 and IEC 61511, ensuring safety and regulatory compliance.

- Compact Design: With its compact and efficient design, the F3003 can fit into systems with limited space, offering high performance without a large footprint.

- Robust Housing: The module is housed in a durable metal casing, offering IP20 protection to withstand environmental conditions in industrial settings.

- Global Certification: Certified for use in hazardous environments (ATEX) and compliant with UL, CE standards, making it suitable for a wide range of industries.

Recent Product News

-

“HIMA F3003: Enhancing Process Safety in Chemical Plants”

- This article discusses the HIMA F3003’s impact on improving safety and reducing risks in the chemical processing industry, including its role in emergency shutdown systems.

-

“HIMA F3003 Controller: The Future of Safety Instrumented Systems”

- A detailed look at how the F3003 is shaping the future of SIS, focusing on its flexibility, scalability, and adherence to the latest safety standards.

-

“HIMA F3003: A Key Player in Oil and Gas Safety Automation”

- This feature highlights the role of the F3003 in safety automation for the oil and gas industry, especially in remote and offshore applications.

-

“Ensuring High Safety Standards with HIMA F3003 in Nuclear Facilities”

- This news release explores how the F3003 meets the stringent requirements of safety-critical systems in nuclear power plants, ensuring operational integrity.

Frequently Asked Questions (FAQ)

-

What is the Safety Integrity Level (SIL) rating of the HIMA F3003?

- The HIMA F3003 is SIL 3 certified according to IEC 61508 and IEC 61511.

-

What types of inputs and outputs does the F3003 support?

- The F3003 supports digital, analog, and fieldbus inputs, as well as digital, analog, and relay outputs.

-

Can the F3003 be used in hazardous areas?

- Yes, the F3003 is certified for use in hazardous areas with ATEX certification.

-

What fieldbus protocols are supported by the F3003?

- The F3003 supports PROFIBUS DP, Modbus, and HART communication protocols.

-

What is the operating temperature range of the F3003?

- The operating temperature range of the F3003 is -20°C to +60°C.

-

What is the power supply requirement for the F3003?

- The F3003 requires a 24 V DC power supply, with a range from 18 V DC to 30 V DC.

-

How is the F3003 mounted?

- The F3003 can be mounted on a DIN rail.

-

What are the diagnostic features of the F3003?

- The F3003 offers advanced diagnostic capabilities, including real-time fault detection and troubleshooting features.

-

What certifications does the F3003 have?

- The F3003 is CE, UL, and ATEX certified and meets international safety standards like IEC 61508 and IEC 61511.

-

How does the F3003 ensure system availability?

- The F3003 features redundancy for both CPU and power supplies (hot standby), ensuring high availability and reliability.

10 Recommended Models

| Model | Description | Key Features |

|---|---|---|

| HIMA F3100 | Distributed safety controller | Suitable for large and distributed industrial systems |

| HIMA F3010 | Small-scale safety controller | Ideal for small machines and applications |

| HIMA F3503 | High-availability safety controller | Dual-redundant configuration for maximum reliability |

| HIMA F3000 | SIL 3 certified controller | High-performance safety solution for critical processes |

| HIMA F5000 | High-end safety controller | Designed for complex industrial environments |

| HIMA F2000 | Entry-level safety controller | Cost-effective solution for basic safety applications |

| HIMA F4000 | Advanced diagnostics safety controller | Suitable for large and complex safety systems |

| HIMA F6000 | Redundant safety controller | Provides high redundancy for safety-critical applications |

| HIMA F3500 | Advanced controller for complex systems | High flexibility and performance |

| HIMA F5100 | Modular and flexible safety controller | Suitable for diverse industrial sectors |

10 Popular Models from HIMA

| Model | Description | Key Features |

|---|---|---|

| HIMA F3003 | Safety-related controller | SIL 3 certified, designed for critical applications |

| HIMA F2000 | Entry-level safety controller | Budget-friendly solution for basic safety applications |

| HIMA F4000 | Advanced safety controller with diagnostics | Designed for large, complex safety systems |

| HIMA F6000 | High-redundancy safety controller | Redundant safety for mission-critical processes |

| HIMA F3500 | High-performance safety controller | Suitable for high-demand, complex systems |

| HIMA F1000 | Basic controller for smaller safety applications | Simple and compact design for small-scale needs |

| HIMA F7000 | Robust and highly reliable safety controller | Excellent for high-risk industrial applications |

| HIMA F9000 | Premium controller for high-end applications | Designed for the most demanding environments |

| HIMA F5000 | Industrial-grade safety controller | High availability for large and diverse systems |

| HIMA F1100 | Flexible safety controller | Suitable for diverse applications across industries |

Excellent PLC

Excellent PLC