| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

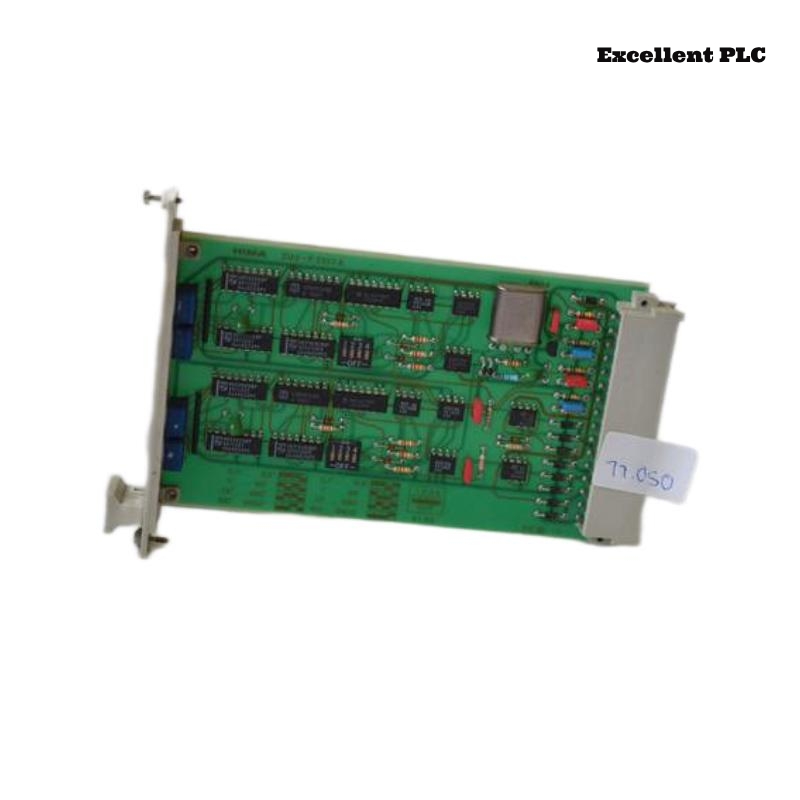

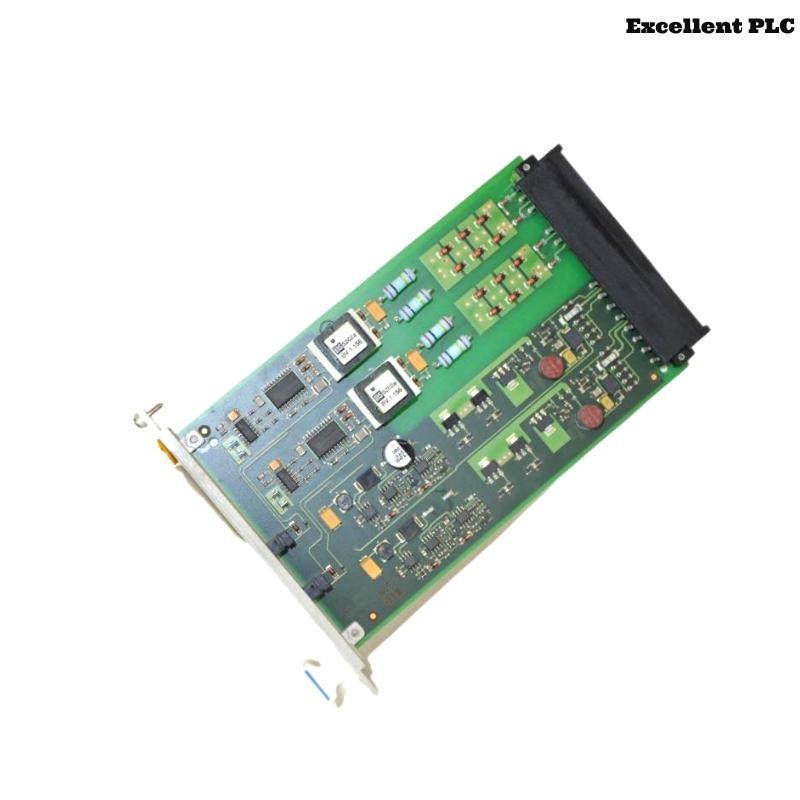

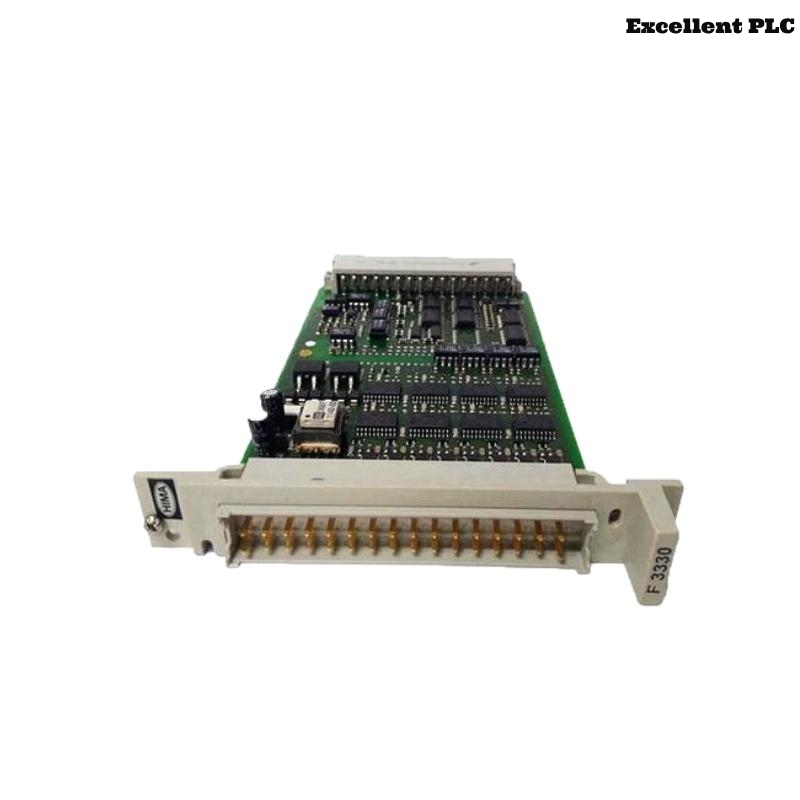

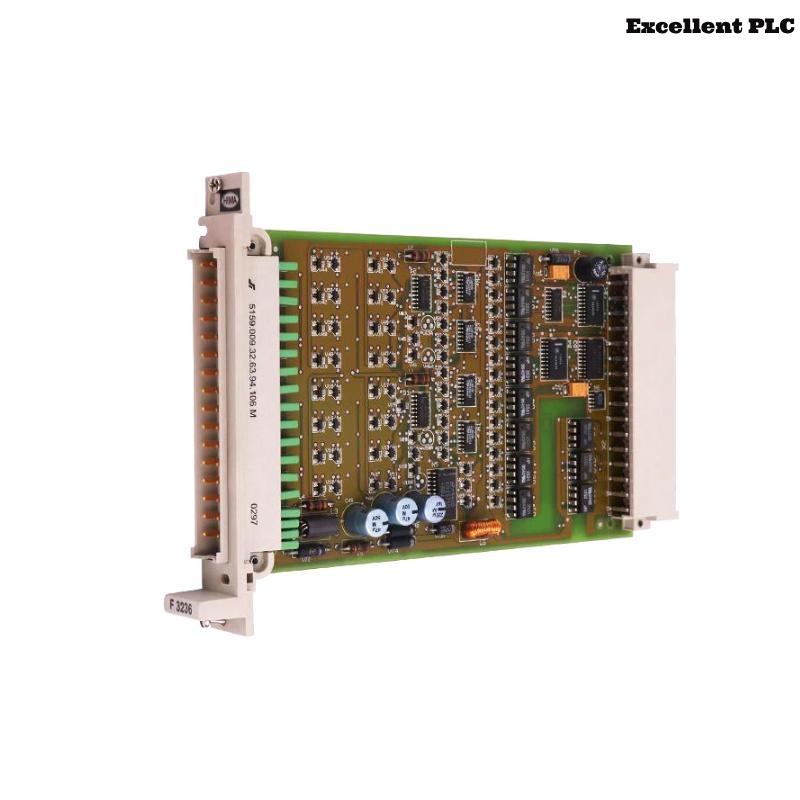

The HIMA F2103a Timer Module is a high-performance, safety-critical component designed for industrial control systems. This module provides accurate time-based control for a wide range of processes, enabling precise timing functions for safety applications. The F2103a is ideal for applications in industries such as chemical, oil & gas, energy, and manufacturing, where high reliability and accurate timing are essential.

This timer module is designed to work within the HIMA safety systems, which are based on a fault-tolerant, modular architecture, ensuring that safety-critical operations continue without interruption. The F2103a supports a variety of timer configurations, such as delay, pulse, and interval timing, which can be easily configured through HIMA’s proprietary software tools.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | HIMA F2103a Timer Module |

| Function | Timer module for process control |

| Input Voltage | 24V DC (nominal) |

| Power Consumption | Approx. 3W |

| Timer Type | Delay, Pulse, Interval |

| Operating Temperature | -25°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95% non-condensing |

| Dimensions | 255 x 114 mm |

| Weight | 2 kg |

| Mounting | DIN rail mounting |

| Response Time | < 5 ms |

| Compliancy | SIL3 certified |

Applications

The HIMA F2103a Timer Module is widely used in safety-critical and industrial applications where precise timing functions are required. Some of its key applications include:

- Process Control: Used for time-based control in manufacturing, chemical, and power plants where accurate timing is crucial for operations such as valve control, pump sequencing, or batch processing.

- Safety Instrumented Systems (SIS): The module plays a key role in controlling timed safety functions and ensuring that safety actions (such as shutdowns or alarms) are triggered at the correct moment.

- Automation Systems: Used to manage the timing of various processes within industrial automation systems, such as conveyor belts, batch processes, or machinery synchronization.

- Energy and Oil & Gas: Provides precise timing control for oil refinery units, gas pipelines, and energy plants where reliability and accuracy are paramount.

- Critical Equipment Protection: Monitors and controls time delays and sequences in equipment protection systems, such as overspeed protection in turbines or shutdown sequences in reactors.

Advantages of HIMA F2103a Timer Module

- High Reliability: Designed to meet SIL3 certification, ensuring high availability in safety-critical applications.

- Flexibility: Supports various timer functions, including delay, pulse, and interval timing, which can be easily configured for different use cases.

- Precise Timing: With a fast response time (<5 ms), the module ensures accurate time control, even in high-speed applications.

- Compact Design: Its compact size (255 x 114 mm) allows it to be easily integrated into control panels with limited space.

- Wide Operating Range: The module operates within a broad temperature range (-25°C to +70°C), making it suitable for harsh industrial environments.

- Energy Efficiency: Consumes minimal power (~3W), which makes it suitable for energy-conscious applications.

- Robust Performance: Provides consistent performance in both standard and safety-critical applications, reducing downtime and improving system reliability.

- Modular Design: Can be easily integrated into existing HIMA safety systems and expanded with other modules for increased functionality.

- Ease of Integration: Offers straightforward configuration through HIMA’s proprietary software tools, allowing for fast setup and troubleshooting.

- Certified Safety: Compliant with international safety standards, providing confidence in safety-critical environments.

Latest News Titles

- March 2025: HIMA F2103a Timer Module successfully integrated into a major chemical plant safety system.

- December 2024: HIMA announces software updates for the F2103a to support advanced timer features.

- September 2024: HIMA F2103a deployed in offshore oil platforms to enhance process reliability.

- July 2024: HIMA expands its portfolio with the F2103a, improving safety instrumented systems (SIS).

- June 2024: F2103a Timer Module passes rigorous testing for high-temperature industrial applications.

Frequently Asked Questions (FAQs)

1. What is the main function of the HIMA F2103a Timer Module?

The F2103a Timer Module provides accurate time-based control functions in safety-critical and industrial applications, including delay, pulse, and interval timing.

2. What industries use the F2103a Timer Module?

Industries such as chemical, oil & gas, power generation, and manufacturing use the F2103a for its precision timing and safety functions.

3. Is the F2103a Timer Module SIL certified?

Yes, the F2103a is SIL3 certified, making it suitable for safety-critical applications.

4. How is the F2103a Timer Module mounted?

The module is mounted on a DIN rail, making it easy to install in standard industrial control panels.

5. What is the power consumption of the F2103a Timer Module?

The module consumes approximately 3W of power during operation.

6. What is the temperature range for the F2103a?

The operating temperature range is -25°C to +70°C, making it suitable for a variety of industrial environments.

7. Can the F2103a be used for process control in manufacturing?

Yes, it is ideal for process control applications such as valve sequencing, pump control, and batch processing in manufacturing.

8. What types of timers does the F2103a support?

The module supports delay, pulse, and interval timers, making it versatile for different time-based control tasks.

9. How can I configure the F2103a Timer Module?

The module can be configured through HIMA’s proprietary software tools, which provide an easy-to-use interface for setup.

10. Is the F2103a suitable for hazardous environments?

Yes, it is designed to operate reliably in harsh industrial environments, including those with high humidity, vibration, and temperature variations.

Related Models (Same Series or Similar Functionality)

| Model Number | Description |

|---|---|

| F2102a | Timer Module with extended features for complex timing functions |

| F2201a | Digital Input Module with timing capabilities |

| F2104a | Advanced Timer Module with enhanced safety features |

| F2301a | Signal Converter Module for integrating timing into systems |

| F2501a | High-speed Timing and Control Module |

| F2303a | Timer and Digital Output Module |

| F2203a | Pulse Input Module with integrated timer functionality |

| F2305a | Safety Timer Module with integrated diagnostic functions |

| F2402a | Power Supply Module for timer-based systems |

| F2502a | Extended Timer Module with adjustable pulse widths |

Popular HIMA Models

| Model Number | Description |

|---|---|

| F2101a | Basic Timer Module for standard process control |

| F2200a | High-performance Digital Input Module |

| F2400a | Advanced Safety Relay Output Module |

| F3101a | Safety Communication Module for distributed systems |

| F3300a | Digital Output Module with fail-safe redundancy |

| F3200a | Advanced Digital Signal Processor for control systems |

| F2001a | Modular Safety Controller for complex applications |

| F3102a | Field Interface Module with integrated diagnostics |

| F3500a | High-capacity Output Module for industrial controls |

| F3401a | Universal Safety I/O Module for flexible applications |

Excellent PLC

Excellent PLC