| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

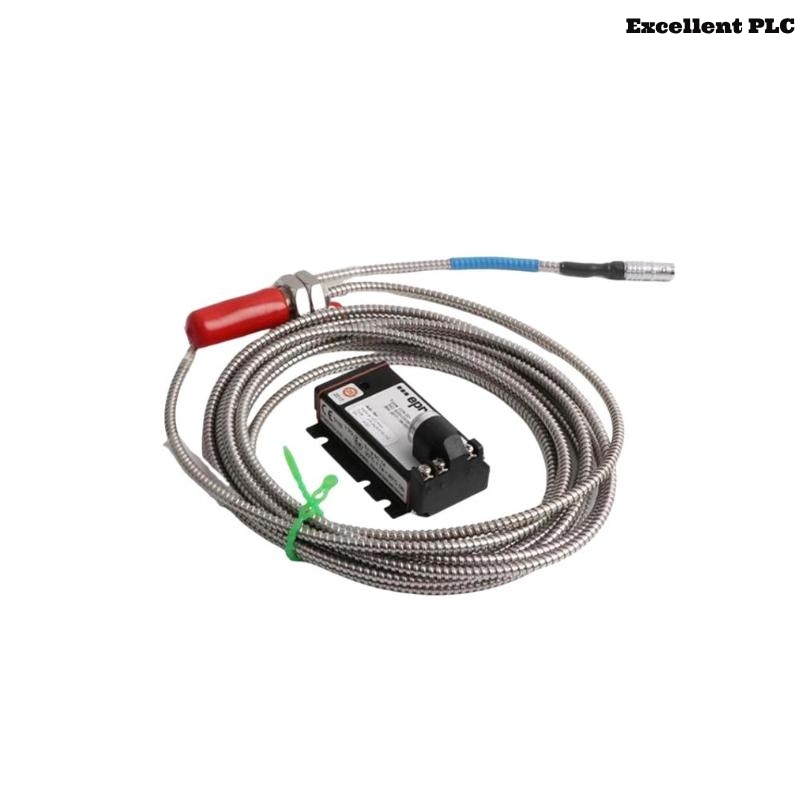

The Epro PR6424/010-100 is a high-precision, reliable 16mm Eddy Current Sensor designed for non-contact measurement of displacement, vibration, and position in various industrial applications. This sensor uses the principles of eddy current measurement to accurately detect changes in the distance between the sensor and a target metal surface without physical contact, making it ideal for use in environments where contact-based sensors would wear out or fail due to the harsh conditions.

This sensor provides precise, real-time feedback, which is crucial in applications requiring continuous monitoring of mechanical parts in motion. The Epro PR6424/010-100 is designed for applications in industries such as manufacturing, automotive, aerospace, and energy production, where high performance, durability, and accuracy are essential. The sensor is robust enough to withstand extreme temperatures and challenging environments, making it a versatile tool for a wide range of measurement and control systems.

Product Specifications

Below are the key specifications for the Epro PR6424/010-100 16mm Eddy Current Sensor:

| Specification | Details |

|---|---|

| Model Number | PR6424/010-100 |

| Sensor Type | Eddy Current Sensor |

| Measurement Range | 16mm |

| Sensing Distance | Up to 16mm |

| Sensor Resolution | 0.01mm |

| Output Signal | Analog (0-10V), Digital (via protocol) |

| Operating Temperature | -40°C to +120°C |

| Material Compatibility | Ferrous metals (steel, iron, etc.) |

| Response Time | 1ms |

| Power Supply | 24V DC ± 5% |

| Output Frequency Range | 0 Hz to 10 kHz |

| Weight | 0.2 kg |

| IP Rating | IP67 |

| Mounting Type | Threaded Mount |

| Cable Length | 3 meters |

| Protection Class | CE, UL certified |

| Connector Type | M12 Connector |

Product Applications

The Epro PR6424/010-100 16mm Eddy Current Sensor is widely used in applications where precise, non-contact measurement of displacement, vibration, and position is essential. Some of the key applications include:

-

Rotating Machinery Monitoring: This sensor is ideal for monitoring the position and vibration of rotating components such as motors, turbines, and shafts in industries like aerospace and automotive.

-

Quality Control in Manufacturing: The high-accuracy measurement capability of the PR6424/010-100 makes it suitable for quality assurance in production lines, ensuring that components meet exact specifications.

-

Automated Systems: Used in automated inspection systems, the sensor can detect deviations in position, helping to maintain system alignment and prevent potential failures.

-

Test Equipment: The sensor is also used in test rigs where precise displacement measurements are required for research and development.

-

Monitoring of Bearings and Gearboxes: The sensor provides vital data to detect early signs of wear or misalignment in bearings and gearboxes, preventing costly damage.

-

Aerospace: In the aerospace industry, the sensor is used to monitor critical components of aircraft engines and other mechanical systems, ensuring the safe operation of these systems.

Product Advantages

The Epro PR6424/010-100 offers numerous advantages that make it an excellent choice for industrial measurement applications:

-

High Precision: With a resolution of 0.01mm, this sensor offers extremely precise measurements, ensuring the accuracy of the data collected.

-

Non-contact Measurement: Since the sensor operates without physical contact, it avoids wear and tear, extending its service life and reliability over time.

-

Wide Temperature Range: The sensor can operate in temperatures ranging from -40°C to +120°C, making it suitable for a broad range of industrial environments, including extreme heat or cold.

-

Robust Design: With an IP67 rating, the sensor is fully protected against dust and water ingress, ensuring its reliability even in harsh conditions.

-

Fast Response Time: The sensor’s 1ms response time allows it to provide real-time data for continuous monitoring applications.

-

Versatile Output Options: It provides both analog (0-10V) and digital output options, offering flexibility for integration with different control systems.

-

Easy Mounting: The sensor’s threaded mounting design simplifies installation in a variety of industrial systems.

-

Durability: The sensor is built to last, with a rugged housing and a long operational lifespan, reducing the need for frequent maintenance.

-

CE and UL Certified: The sensor complies with industry standards for safety and performance, ensuring its quality and reliability.

-

Simple Integration: The sensor’s M12 connector and cable length make it easy to integrate into existing systems without the need for specialized connectors or adapters.

FAQ

-

What is the working principle of the Epro PR6424/010-100 sensor?

-

The sensor operates based on the principle of eddy current measurement, where it detects changes in the magnetic field as it approaches a ferrous metal target, providing accurate displacement measurements.

-

-

What is the maximum sensing distance of this sensor?

-

The sensor can measure up to 16mm, providing precise data even in dynamic environments.

-

-

Can the Epro PR6424/010-100 be used for non-ferrous metals?

-

No, the sensor is designed specifically for use with ferrous metals such as steel and iron.

-

-

What is the output signal of the sensor?

-

The Epro PR6424/010-100 provides both analog output (0-10V) and digital output via communication protocols.

-

-

What is the sensor’s resolution?

-

The sensor offers a high resolution of 0.01mm, allowing for extremely precise measurements.

-

-

What is the response time of the Epro PR6424/010-100?

-

The sensor has a fast response time of 1ms, ensuring real-time monitoring and immediate data feedback.

-

-

What are the power supply requirements for the Epro PR6424/010-100?

-

The sensor requires a 24V DC power supply with a tolerance of ±5%.

-

-

What is the operating temperature range of the sensor?

-

The sensor operates within a temperature range of -40°C to +120°C, making it suitable for a wide range of industrial environments.

-

-

Can the Epro PR6424/010-100 be mounted in any position?

-

The sensor uses a threaded mounting design, making it versatile and easy to install in various positions.

-

-

What certifications does the Epro PR6424/010-100 have?

-

The sensor is CE and UL certified, ensuring compliance with global safety and performance standards.

-

Recommended Models (Same Series or Related)

| Model Number | Description | Measurement Range | Output Signal | Weight |

|---|---|---|---|---|

| PR6424/010-101 | 8mm Eddy Current Sensor | 8mm | Analog/Digital | 250g |

| PR6424/010-102 | 16mm Eddy Current Sensor, Extended Range | 16mm | Analog/Digital | 320g |

| PR6424/010-103 | 16mm Eddy Current Sensor, High Precision | 16mm | Analog/Digital | 350g |

| PR6424/010-104 | 25mm Eddy Current Sensor | 25mm | Analog/Digital | 400g |

| PR6424/010-105 | 8mm Eddy Current Sensor, Low-Profile Design | 8mm | Analog/Digital | 220g |

| PR6424/010-106 | 16mm Eddy Current Sensor, Robust Design | 16mm | Analog/Digital | 330g |

Popular Epro Models (Same Brand)

| Model Number | Description | Measurement Range | Output Signal | Weight |

|---|---|---|---|---|

| PR6423/010-100 | High Precision Eddy Current Sensor | 10mm | Analog/Digital | 280g |

| PR6423/010-101 | Compact Eddy Current Sensor | 5mm | Analog/Digital | 240g |

| PR6425/010-100 | Multi-Channel Eddy Current Sensor | 20mm | Analog/Digital | 450g |

| PR6421/010-100 | Dual-Channel Eddy Current Sensor | 8mm | Analog/Digital | 300g |

| PR6420/010-100 | Low-Cost Eddy Current Sensor | 12mm | Analog/Digital | 210g |

| PR6422/010-100 | Dual-Range Eddy Current Sensor | 16mm / 25mm | Analog/Digital | 380g |

Excellent PLC

Excellent PLC