| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

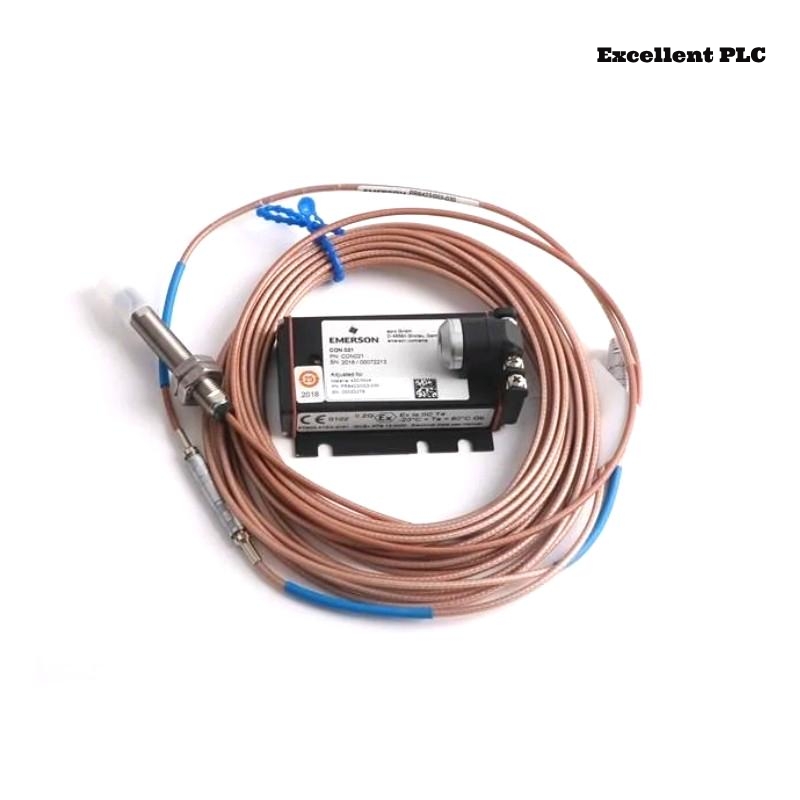

The Epro PR6423/012-120 is a high-precision eddy current sensor designed for non-contact vibration and displacement measurement in industrial machinery. This sensor is widely used in turbomachinery, rotating equipment, and critical asset monitoring. It provides reliable and accurate measurements, ensuring early detection of mechanical failures and enabling predictive maintenance.

With an 8mm measuring range, this sensor is suitable for detecting small yet critical displacements in machine components. It is often paired with Epro CON011 or CON021 signal converters to deliver high-quality data for industrial automation and process control applications.

Product Specifications

| Parameter | Value |

|---|---|

| Model | PR6423/012-120 |

| Sensor Type | Eddy Current Sensor |

| Sensor Head Diameter | 8mm |

| Frequency Range | 0 – 10 kHz |

| Supply Voltage | -24V DC |

| Sensitivity | 7.87 mV/μm |

| Linear Deviation | ≤ 1% of Full Scale |

| Operating Temperature | -35°C to +180°C |

| Storage Temperature | -40°C to +200°C |

| Protection Class | IP67 (Dustproof & Waterproof) |

| Weight | 0.1 kg |

| Cable Length | Customizable (Standard: 5m, 9m) |

| Material | Stainless Steel (Corrosion-resistant) |

Product Applications

-

Turbomachinery Monitoring – Used in turbines, compressors, and pumps for vibration analysis.

-

Rotating Equipment Condition Monitoring – Ensures the reliability of rotating shafts and bearings.

-

Power Generation Plants – Critical for gas and steam turbine condition monitoring.

-

Oil & Gas Industry – Prevents catastrophic failures in refinery and petrochemical equipment.

-

Industrial Automation – Used in smart condition monitoring systems.

-

Aerospace Engineering – Supports non-contact precision measurements.

-

Heavy Machinery & Manufacturing – Ensures stability and alignment of large industrial machines.

Product Advantages

-

High Precision Measurement – Provides accurate vibration and displacement readings.

-

Non-Contact Sensing – Minimizes wear and tear, extending sensor lifespan.

-

Rugged Design – Resistant to harsh industrial environments (IP67-rated).

-

Broad Temperature Tolerance – Suitable for extreme operating conditions.

-

Versatile Applications – Compatible with various industrial monitoring systems.

-

Seamless Integration – Works with Epro MMS and Bently Nevada monitoring systems.

-

Low Maintenance – Designed for long-term use with minimal calibration.

-

Fast Response Time – Ensures real-time monitoring and immediate anomaly detection.

Latest News Titles

-

“Epro PR6423/012-120: A Benchmark in Eddy Current Sensing for Industrial Applications”

-

“Advancements in Predictive Maintenance: How Eddy Current Sensors Enhance Machine Reliability”

-

“Comparing Epro PR6423 Series with Industry Alternatives: A Comprehensive Review”

-

“Why Non-Contact Vibration Monitoring is the Future of Industrial Asset Management”

-

“The Role of Eddy Current Sensors in Gas and Steam Turbine Protection”

-

“Enhancing Rotating Equipment Reliability with Epro PR6423/012-120 Sensors”

-

“How Eddy Current Sensors Help Reduce Unplanned Downtime in Manufacturing”

-

“Epro PR6423/012-120: Best Practices for Installation and Calibration”

Frequently Asked Questions (FAQ)

-

What is the measurement range of the Epro PR6423/012-120 sensor?

-

It has a measurement range of 8mm, suitable for precise displacement monitoring.

-

-

What type of output does this sensor provide?

-

It provides an analog voltage output, typically paired with signal converters like CON011 or CON021.

-

-

Is this sensor compatible with Bently Nevada systems?

-

Yes, it is compatible with various industrial monitoring systems, including Bently Nevada.

-

-

What is the operating temperature range of this sensor?

-

The sensor operates between -35°C to +180°C and can be stored in conditions up to 200°C.

-

-

Can the sensor be used in hazardous environments?

-

Yes, the stainless steel housing and IP67 protection make it suitable for harsh environments.

-

-

How do I install the PR6423/012-120 sensor?

-

It should be installed at a fixed distance from the target surface, with alignment ensured for accurate measurement.

-

-

What signal converter should I use with this sensor?

-

The recommended converters are Epro CON011 or CON021 for optimal signal processing.

-

-

Does the sensor require regular maintenance?

-

It requires minimal maintenance, though periodic inspections are recommended to ensure accuracy.

-

-

Can I customize the cable length?

-

Yes, standard cable lengths are 5m and 9m, but custom lengths are available upon request.

-

-

What industries commonly use this sensor?

-

It is widely used in power plants, oil & gas refineries, aerospace, and heavy manufacturing.

-

Related Models (Same Series or Similar Functionality)

| Model | Measurement Range | Cable Length | Application |

|---|---|---|---|

| PR6423/010-000 | 8mm | 5m | General Industrial Use |

| PR6423/011-010 | 8mm | 9m | High-Temperature Areas |

| PR6423/002-030 | 8mm | 5m | Power Plant Equipment |

| PR6423/003-010 | 8mm | 5m | Steam and Gas Turbines |

| PR6423/004-010 | 8mm | 9m | Oil & Gas Industry |

| PR6423/005-010 | 8mm | 5m | Compressor Vibration Monitoring |

| PR6423/009-010 | 8mm | 9m | Manufacturing Machinery |

| PR6423/001-000 | 8mm | Customizable | Aerospace Engineering |

Popular Models from the Same Brand (Epro)

| Model | Type | Application |

|---|---|---|

| PR6424/014-040 | Eddy Current Sensor | High-Temperature Monitoring |

| PR6425/010-140 | Proximity Sensor | Turbomachinery Vibration Analysis |

| MMS6312/022-100 | Vibration Monitoring Module | Industrial Equipment Protection |

| MMS3120/022-100 | Diagnostic Monitoring Module | Predictive Maintenance |

| CON021 | Signal Converter | Eddy Current Sensor Compatibility |

| CON011 | Signal Converter | Epro PR6423 Series Integration |

| PR6426/000-030 | Displacement Sensor | Heavy Machinery Condition Monitoring |

| PR9268/300-000 | Speed Sensor | Rotational Speed Measurement |

Excellent PLC

Excellent PLC