| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

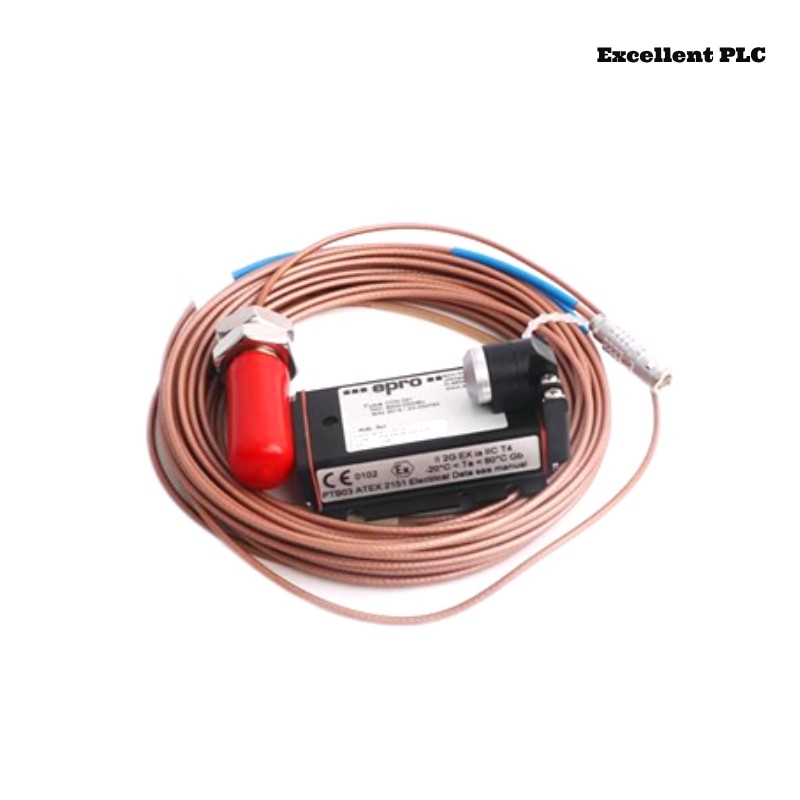

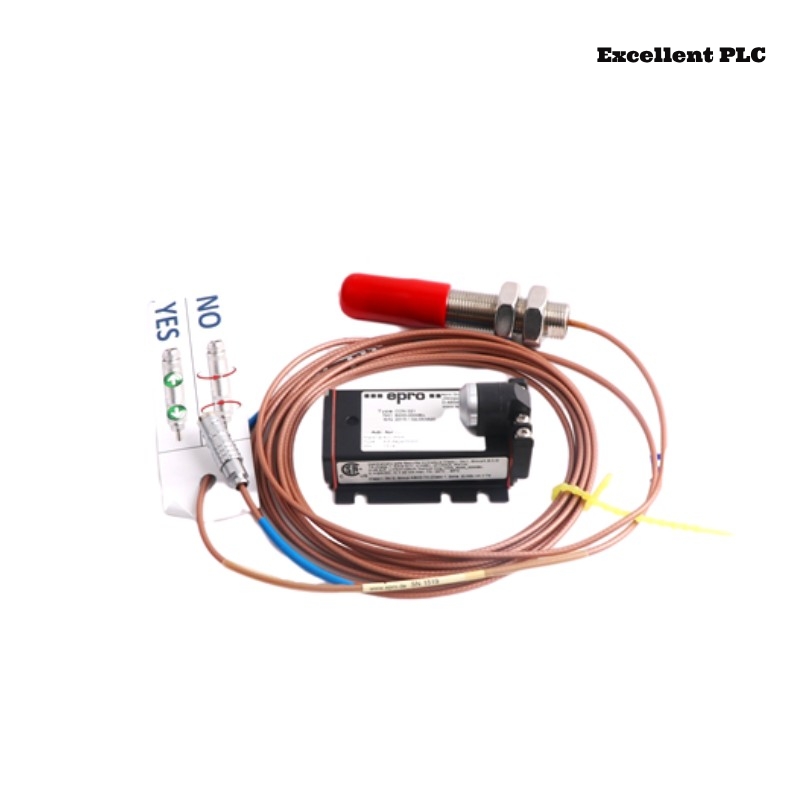

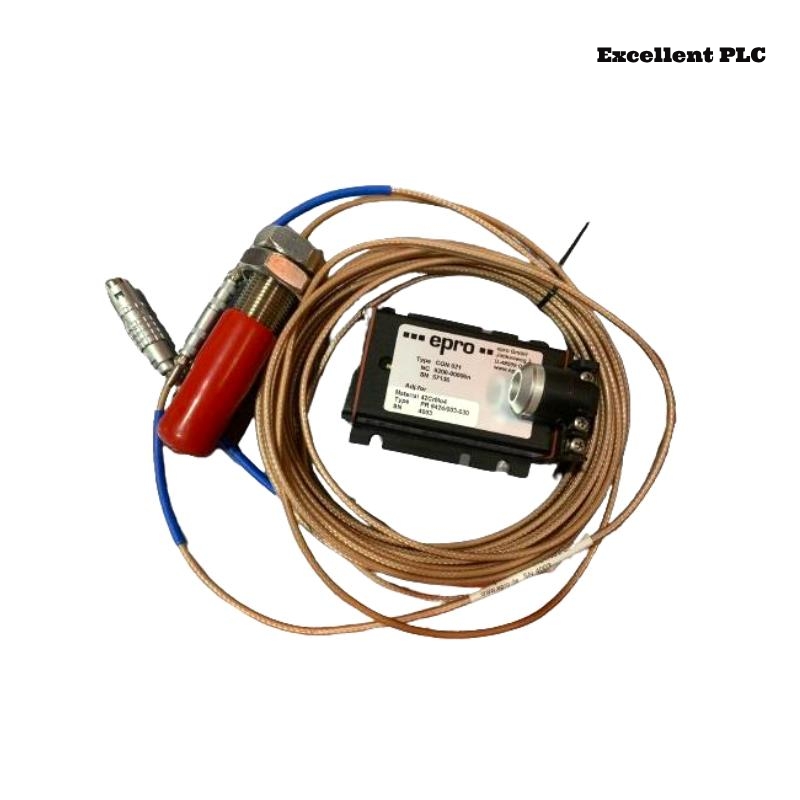

The Epro PR6423/010-100+CON021 8mm Eddy Current Sensor is a high-precision measurement solution designed to detect displacement, vibration, and position changes in rotating machinery. This combination of the Epro PR6423/010-100 Eddy Current Sensor and the CON021 signal converter enhances its versatility and reliability in a wide range of industrial applications. Together, they provide accurate, non-contact measurements, offering a solution to the growing demand for real-time condition monitoring in industries such as power generation, heavy machinery, and aerospace.

The Epro PR6423/010-100 sensor uses eddy current technology to detect movement in metallic surfaces, while the CON021 signal converter converts the sensor’s analog signals into formats compatible with various monitoring systems, including Epro MMS systems. This makes the PR6423/010-100+CON021 combination ideal for industries that require precise diagnostics, continuous monitoring, and predictive maintenance solutions.

Product Specifications

| Specification | Details |

|---|---|

| Manufacturer | Epro (Emerson) |

| Model Number | PR6423/010-100+CON021 |

| Measurement Principle | Eddy Current Technology |

| Sensor Head Diameter | 8mm |

| Output Signal | Analog Output (with CON021 conversion) |

| Power Supply | Typically 24V DC |

| Temperature Range | -35°C to 125°C |

| Environmental Protection | IP67 (Dustproof and Waterproof) |

| Housing Material | Stainless Steel |

| Mounting Type | Threaded or Flange Mounting |

| Weight | 0.22 kg |

| Signal Conversion | Analog to Digital Signal with CON021 |

| Cable Length | Standard and Custom Lengths Available |

Applications

The Epro PR6423/010-100+CON021 is used in a wide array of industries and applications, including:

-

Turbine Condition Monitoring – Measures shaft displacement and vibration in turbines to prevent failure.

-

Compressor Monitoring – Tracks the performance of high-speed compressors to avoid mechanical damage.

-

Pump and Fan Systems – Ensures the continuous, efficient operation of pumps and fans in industrial settings.

-

Industrial Motors – Detects unbalanced forces, vibration, and displacement in motors to prevent premature failure.

-

Gearbox Systems – Monitors wear and tear, as well as alignment in industrial gearboxes.

-

Aerospace – Monitors rotating machinery in aircraft engines and other high-precision applications.

-

Power Generation – Helps in the early detection of faults in generators and turbines in power plants.

-

Oil & Gas Industry – Monitors pumps and motors in harsh environments where reliability is critical.

Product Advantages

-

Non-Contact Measurement – The sensor operates without touching the monitored surface, ensuring no mechanical wear.

-

High Sensitivity and Accuracy – Provides extremely precise readings, even for small displacements.

-

Wide Operating Temperature Range – The sensor functions optimally between -35°C to 125°C, making it suitable for diverse environments.

-

Durable and Reliable – The stainless steel housing and IP67 protection ensure it withstands harsh industrial environments.

-

Signal Conversion Capability – The CON021 converts the analog output from the sensor into compatible signals for a variety of systems, expanding its versatility.

-

Reduced Maintenance Costs – Helps in detecting issues early, which reduces unplanned downtime and maintenance costs.

-

Seamless Integration – Easily integrates with Epro MMS and other monitoring systems.

-

Real-Time Monitoring – Provides real-time data for predictive maintenance and decision-making.

-

Cost-Effective Solution – Low maintenance and high durability make it a cost-effective option for continuous operation.

-

Flexible Mounting – Can be mounted using threaded or flange types, providing ease of installation in different machinery setups.

Latest News Titles

-

“Epro PR6423/010-100+CON021: Revolutionizing Vibration Monitoring with Non-Contact Technology”

-

“How Epro’s Eddy Current Sensors Are Reducing Downtime in Turbine Operations”

-

“Emerson Enhances Its Industrial Monitoring Solutions with the Epro PR6423/010-100+CON021”

-

“Integrating Analog to Digital Conversion for Real-Time Monitoring: The Role of the CON021 Signal Converter”

-

“Epro PR6423/010-100+CON021: Advanced Tools for Predictive Maintenance in Heavy Machinery”

-

“Innovative Measurement Systems for Power Generation: The Power of Epro’s Eddy Current Sensors”

-

“Why Epro’s Combined Eddy Current Sensor and Signal Converter is a Game-Changer in Condition Monitoring”

-

“Emerson’s Epro PR6423/010-100+CON021 Sets New Standards for Shaft Vibration Measurement”

-

“How the Epro PR6423/010-100+CON021 Enhances Monitoring Systems in Oil & Gas Industries”

-

“The Future of Industrial Sensors: Epro’s Solutions for Early Fault Detection and Prevention”

Frequently Asked Questions (FAQ)

-

What is the primary function of the Epro PR6423/010-100+CON021?

This system provides precise, non-contact measurement of shaft displacement, vibration, and position, which is essential for predictive maintenance and monitoring. -

How does the CON021 improve the sensor’s functionality?

The CON021 signal converter allows the sensor’s analog output to be converted into a digital format, making it compatible with modern monitoring systems. -

What is the output signal type of the Epro PR6423/010-100?

The sensor outputs analog voltage signals, which are converted by the CON021 to be used with digital monitoring systems. -

What industries use this sensor?

This sensor is used in power generation, aerospace, oil and gas, heavy machinery, and industrial motors for condition monitoring. -

Can the Epro PR6423/010-100 be used in high-speed machinery?

Yes, the sensor is ideal for high-speed machinery, where precise measurement of vibrations and displacements is critical. -

How does this sensor handle harsh environments?

The sensor’s IP67 rating ensures it is resistant to dust, water, and other environmental contaminants, making it suitable for challenging industrial environments. -

What is the operating temperature range of this sensor?

The sensor operates efficiently in temperatures ranging from -35°C to 125°C. -

What types of mounting options are available?

The sensor can be mounted using either threaded or flange mounting, offering flexibility for different machinery setups. -

How often does the Epro PR6423/010-100 require maintenance?

This sensor requires minimal maintenance due to its non-contact measurement system, which reduces wear and tear over time. -

What makes the Epro PR6423/010-100+CON021 better than other vibration sensors?

The combination of non-contact measurement, high accuracy, and real-time monitoring capabilities makes this system ideal for continuous, precise monitoring of rotating machinery.

Recommended Related Models

| Model | Description |

|---|---|

| PR6423/000-000 | Basic Eddy Current Sensor |

| PR6423/005-010 | High-Sensitivity Eddy Current Sensor |

| PR6423/002-030 | Compact Eddy Current Sensor |

| PR6423/004-010 | Extended-Range Eddy Current Sensor |

| PR6423/007-100 | High-Temperature Eddy Current Sensor |

| PR6423/009-030 | Ultra-High Sensitivity Eddy Current Sensor |

| PR6423/001-010 | General-Purpose Eddy Current Sensor |

| PR6423/008-040 | Low-Noise Eddy Current Sensor |

Popular Models from Epro (Emerson)

| Model | Description |

|---|---|

| MMS3120/022-100 | Multi-Channel Vibration Monitoring System |

| MMS3125/022-020 | Advanced Vibration Monitoring Unit |

| PR6424/014-040 | High-Performance Proximity Sensor |

| MMS6312 | Digital Machinery Monitoring and Protection |

| MMS6350 | Industrial Diagnostics System |

| PR6424/01CS | Condition Monitoring Sensor |

| MMS6410 | Modular Machinery Protection System |

| CON021 | Signal Converter for Epro Sensors |

Excellent PLC

Excellent PLC