| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Description

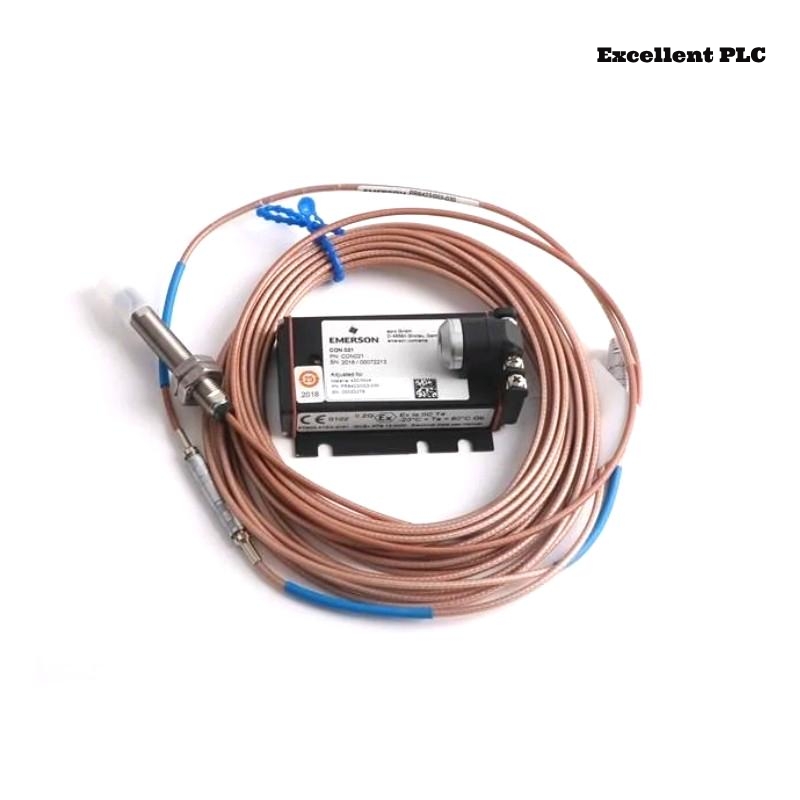

The Epro PR6423/010-100 is an 8mm eddy current sensor designed for high-precision measurement of shaft displacement, vibration, and position in rotating machinery. Manufactured by Epro (a part of Emerson), this sensor is widely used in industrial applications such as turbines, compressors, pumps, and generators. It is engineered to provide highly accurate, non-contact measurement of metallic surfaces, making it ideal for monitoring critical equipment in harsh environments.

With robust construction, high sensitivity, and excellent long-term stability, the PR6423/010-100 is a key component in condition monitoring and predictive maintenance systems, ensuring operational reliability and reducing unexpected downtime.

Product Specifications

| Specification | Details |

|---|---|

| Manufacturer | Epro (Emerson) |

| Model Number | PR6423/010-100 |

| Measurement Principle | Eddy Current Technology |

| Sensor Head Diameter | 8mm |

| Output Signal | Analog Voltage Output |

| Frequency Response | Wideband for High-Speed Vibration Monitoring |

| Power Supply | Typically 24V DC |

| Operating Temperature | -35°C to 125°C |

| Environmental Protection | IP67 (Dustproof and Waterproof) |

| Cable Length | Standard and Custom Lengths Available |

| Compatible Systems | Epro MMS Series, Emerson Machinery Monitoring |

| Housing Material | Stainless Steel |

| Mounting Type | Threaded or Flange Mount |

| Weight | 0.1 kg |

Product Applications

The Epro PR6423/010-100 is widely used in industrial and power generation applications where precise non-contact measurement is required. Its key applications include:

-

Turbine Monitoring – Used to measure shaft displacement and vibration in steam and gas turbines.

-

Compressor Systems – Ensures accurate monitoring of axial and radial movement in high-speed compressors.

-

Pumps & Fans – Detects misalignment, unbalance, and excessive vibration in rotating pumps and fans.

-

Gearbox Condition Monitoring – Tracks wear and misalignment in industrial gear systems.

-

Hydroelectric and Thermal Power Plants – Used for vibration monitoring in generators and turbines.

-

Oil & Gas Industry – Plays a crucial role in maintaining the reliability of drilling and refining equipment.

-

Aerospace and Defense – Used in high-speed rotating systems for precision diagnostics.

-

Steel and Heavy Machinery – Helps detect bearing wear and machine misalignment in heavy-duty industries.

Product Advantages

-

Non-Contact Measurement – Ensures precise and reliable displacement monitoring without mechanical wear.

-

High Sensitivity – Detects minute changes in shaft movement and vibration.

-

Robust Construction – Stainless steel housing provides durability in extreme environments.

-

Wide Temperature Range – Operates effectively from -35°C to 125°C, suitable for various industries.

-

IP67 Protection – Resistant to dust, moisture, and contaminants.

-

Seamless Integration – Compatible with Epro MMS monitoring systems and third-party setups.

-

Long-Term Stability – Designed for continuous operation with minimal drift.

-

High Frequency Response – Ideal for high-speed rotating machinery.

-

Flexible Mounting Options – Supports multiple installation methods for different industrial needs.

-

Cost-Effective Maintenance – Reduces unplanned downtime and extends equipment lifespan.

Latest News Titles

-

“Epro PR6423/010-100: Advancing Industrial Vibration Monitoring Technology”

-

“How Eddy Current Sensors Enhance Predictive Maintenance Strategies”

-

“Emerson Expands Epro PR6423 Series for High-Precision Shaft Displacement Measurement”

-

“Reducing Equipment Downtime with Advanced Non-Contact Sensors”

-

“Why the Epro PR6423/010-100 is a Game-Changer for Industrial Condition Monitoring”

-

“The Role of Eddy Current Sensors in Gas Turbine Performance Optimization”

-

“Integrating PR6423 Sensors with Digital Monitoring Systems: A Step Towards Industry 4.0”

-

“Choosing the Right Vibration Sensor: Epro PR6423 vs. Other Technologies”

-

“Emerson’s PR6423 Series: Increasing Efficiency in Power Generation Plants”

-

“Advancements in Eddy Current Sensor Technology for Heavy Machinery Applications”

Frequently Asked Questions (FAQ)

-

What is the primary function of the Epro PR6423/010-100?

It is used for non-contact measurement of shaft displacement, vibration, and position in rotating machinery. -

What industries commonly use this sensor?

It is widely used in power plants, oil & gas, aerospace, and heavy machinery applications. -

Is this sensor compatible with Epro MMS monitoring systems?

Yes, it is fully compatible with Epro MMS and Emerson machinery monitoring systems. -

What type of signal does the sensor output?

It provides an analog voltage output for condition monitoring systems. -

Can this sensor withstand harsh environmental conditions?

Yes, it has an IP67 rating, ensuring protection against dust and water ingress. -

How is the sensor installed?

It supports threaded or flange mounting, depending on the application requirements. -

What is the operating temperature range of this sensor?

It operates between -35°C and 125°C, making it suitable for extreme environments. -

What makes eddy current sensors better than traditional contact sensors?

No mechanical wear, higher accuracy, and better long-term stability compared to contact sensors. -

Does the PR6423/010-100 require regular maintenance?

Minimal maintenance is required, as it operates with high stability and reliability. -

What is the weight and size of this sensor?

It weighs 0.1 kg and has sensor head diameter of 8 mm.

Recommended Related Models

| Model | Description |

|---|---|

| PR6423/000-000 | Standard Eddy Current Sensor |

| PR6423/005-010 | High-Precision Eddy Current Sensor |

| PR6423/002-030 | Compact Eddy Current Sensor |

| PR6423/004-010 | Extended-Range Eddy Current Sensor |

| PR6423/007-100 | High-Temperature Eddy Current Sensor |

| PR6423/009-030 | Ultra-High Sensitivity Eddy Current Sensor |

| PR6423/001-010 | General-Purpose Eddy Current Sensor |

| PR6423/008-040 | Low-Noise Eddy Current Sensor |

Popular Models from Epro (Emerson)

| Model | Description |

|---|---|

| MMS3120/022-100 | Multi-Channel Vibration Monitor |

| MMS3125/022-020 | High-Speed Data Acquisition Module |

| PR6424/014-040 | High-Performance Proximity Sensor |

| MMS6312 | Advanced Machinery Protection System |

| MMS6350 | Industrial Monitoring & Diagnostic System |

| PR6424/01CS | Condition Monitoring Sensor |

| MMS6410 | Digital Signal Processing Unit |

| CON021 | Signal Converter for Proximity Sensors |

Excellent PLC

Excellent PLC