| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

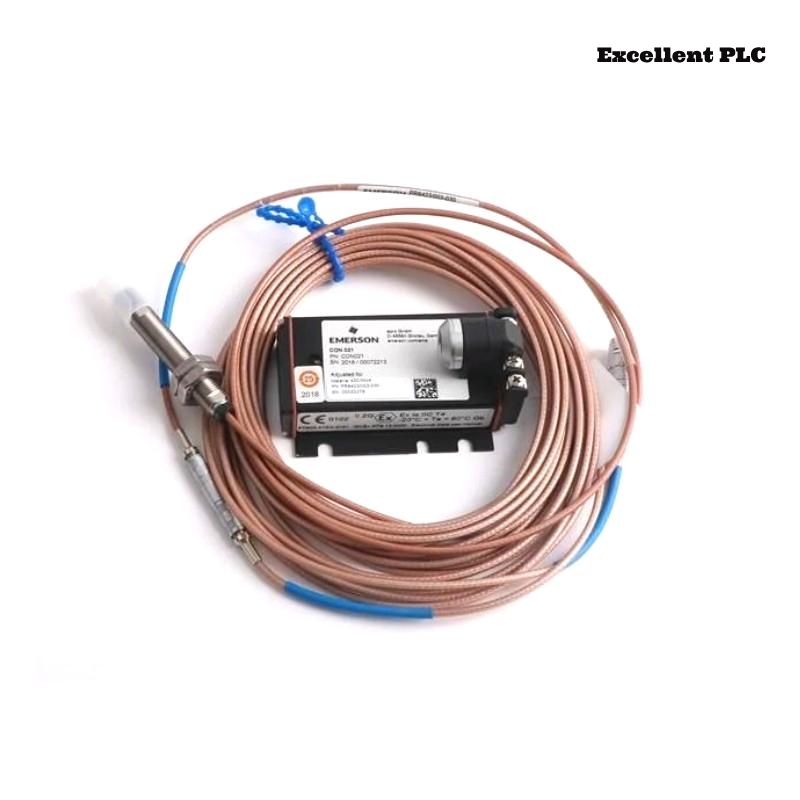

The Epro PR6423/002-030 8mm Eddy Current Sensor is a high-performance sensor designed for precise, non-contact measurement of displacement, distance, and vibration. Utilizing eddy current technology, it provides highly accurate data even in challenging industrial environments. This sensor is ideal for applications where precise, real-time monitoring is essential, such as machinery health diagnostics, vibration analysis, and process control.

Unlike traditional mechanical sensors, the PR6423/002-030 operates without physical contact, ensuring longer operational lifetimes, eliminating wear and tear, and improving reliability. It is particularly suitable for measuring the position of rotating or moving parts, like shafts and bearings, without risk of damage or interference. Additionally, its 8mm sensing range makes it highly versatile in a wide range of industrial and engineering applications.

This model is designed for high-precision industrial applications, offering excellent performance in extreme environmental conditions. It is used extensively in sectors such as automotive, aerospace, power generation, robotics, and manufacturing, where performance and reliability are of utmost importance.

Product Specifications

| Parameter | Details |

|---|---|

| Model | Epro PR6423/002-030 8mm Eddy Current Sensor |

| Technology | Eddy Current Sensor |

| Sensing Range | 8mm |

| Measuring Principle | Eddy current displacement measurement |

| Output Type | Analog (0-10V, 4-20mA) or Digital |

| Mounting Type | Flush, Non-Contact |

| Operating Temperature | -40°C to +120°C |

| Storage Temperature | -40°C to +85°C |

| Weight | 0.1 kg |

| Sensor Head Diameter | 8mm |

| Resolution | 0.1 µm |

| Voltage Supply | 10V DC to 30V DC |

| Frequency Response | Up to 100 kHz |

| Output Signal | 0-10V, 4-20mA, Digital |

| Protection Class | IP67 (Dust and Water Resistant) |

| Material | Stainless Steel Body |

| Response Time | 1 ms (Fast Response) |

| Application Area | Industrial Automation, Machinery Monitoring |

Applications

The Epro PR6423/002-030 8mm Eddy Current Sensor is highly versatile and can be applied across a wide range of industries where precision, durability, and reliability are required. Some of its key applications include:

- Rotating Machinery Monitoring: Perfect for measuring the displacement and vibration of rotating machinery such as motors, turbines, and pumps.

- Condition Monitoring: Provides real-time monitoring of critical components like shafts, bearings, and gears, helping to detect early signs of failure.

- Process Control: The sensor helps maintain control over automated systems, ensuring smooth operation in production lines and manufacturing environments.

- Vibration Monitoring: Measures vibrations in various equipment to ensure that machinery is operating within optimal parameters, preventing catastrophic failures.

- Aerospace: In aircraft engines and parts, the sensor helps monitor conditions to ensure reliability and safety.

- Automotive Manufacturing: Used in the assembly line to ensure precision in parts placement and alignment.

- Power Generation: Provides continuous monitoring of turbine and generator systems, improving operational reliability in power plants.

- Structural Health Monitoring: Detects small displacements or deformations in structures such as bridges and buildings, helping in early detection of structural issues.

- Robotics: Utilized in robotics to provide accurate displacement and position feedback, crucial for precision automation.

- Testing and Quality Control: Commonly used in laboratories and manufacturing facilities to test and inspect parts with high accuracy requirements.

Advantages

- Non-Contact Measurement: The sensor uses eddy current technology to measure displacement without physical contact, reducing wear and tear on machinery.

- High Precision: Offers an excellent resolution of 0.1 µm, making it ideal for applications requiring high precision.

- Wide Sensing Range: With an 8mm sensing range, it offers great flexibility for measuring a variety of displacement and vibration parameters.

- Robust and Durable: Constructed with a stainless steel housing and rated at IP67, the sensor can withstand harsh environments, including exposure to dust, dirt, and water.

- Real-Time Monitoring: Its fast response time of just 1 ms ensures real-time monitoring of critical systems, enhancing process control and machine health monitoring.

- Wide Temperature Range: The sensor can operate in temperatures from -40°C to +120°C, making it suitable for demanding applications in extreme environments.

- Flexible Output Options: It provides multiple output options, including both analog (0-10V, 4-20mA) and digital signals, for seamless integration into various control systems.

- Minimal Power Consumption: The sensor operates efficiently with a low voltage supply range of 10V DC to 30V DC, making it energy-efficient.

- Easy Integration: Its compact design and compatibility with standard systems make it easy to integrate into existing monitoring systems without complex setup.

- Extended Operational Lifespan: As a non-contact sensor, it has a longer operational lifespan compared to traditional contact-based sensors, which require regular maintenance.

Latest News

- “Epro Releases New PR6423/002-030 Eddy Current Sensor for Industrial Applications”

- “Enhanced Accuracy and Durability with Epro PR6423 Eddy Current Sensors”

- “Non-Contact Sensors Revolutionize Condition Monitoring in Power Plants”

- “Epro’s 8mm Eddy Current Sensor: Improving Precision in Aerospace Engineering”

- “Epro’s New PR6423/002-030 Enhances Vibration Monitoring Capabilities”

- “Epro’s Latest Eddy Current Sensors Deliver Superior Performance in Automotive Manufacturing”

- “PR6423/002-030 Eddy Current Sensor: The Future of Non-Contact Measurement”

- “Epro Advances Real-Time Monitoring with New Eddy Current Sensor Technology”

- “How Epro’s Eddy Current Sensors are Shaping the Future of Industrial Automation”

- “PR6423/002-030 Eddy Current Sensor Optimizes Machinery Health Diagnostics”

FAQ

-

What is the working principle of the Epro PR6423/002-030 sensor?

- The sensor works based on the eddy current principle, which uses induced currents to measure the displacement and vibration of conductive materials without physical contact.

-

What is the sensing range of the Epro PR6423/002-030 sensor?

- The sensor has a sensing range of 8mm, making it ideal for precise measurements in various industrial applications.

-

What industries can benefit from using this sensor?

- Industries such as power generation, aerospace, automotive manufacturing, robotics, and structural health monitoring can benefit from this sensor.

-

What are the output options available with the PR6423/002-030 sensor?

- The sensor offers both analog (0-10V, 4-20mA) and digital output signals, ensuring compatibility with a variety of industrial control systems.

-

What is the protection class of the PR6423/002-030?

- The sensor is rated IP67, which makes it dust-tight and resistant to water immersion, allowing it to be used in harsh environments.

-

How is the PR6423/002-030 mounted?

- The sensor is designed for flush mounting, ensuring that it can be integrated into equipment with minimal space requirements.

-

What is the operating temperature range of the Epro PR6423/002-030?

- The sensor operates in temperatures ranging from -40°C to +120°C, making it suitable for both cold and hot environments.

-

What is the resolution of the PR6423/002-030 sensor?

- The sensor has a high resolution of 0.1 µm, allowing for highly accurate displacement and vibration measurements.

-

Is the sensor energy-efficient?

- Yes, the sensor operates within a voltage supply range of 10V DC to 30V DC, making it energy-efficient for continuous operation.

-

What is the response time of the PR6423/002-030 sensor?

- The sensor has an extremely fast response time of 1 ms, ensuring real-time measurement and feedback for critical monitoring applications.

Recommended Models

| Model | Description | Applications |

|---|---|---|

| Epro PR6423/002-010 | 10mm Eddy Current Sensor | Industrial machinery monitoring |

| Epro PR6423/003-000 | High-speed Eddy Current Sensor | Aerospace, Automotive |

| Epro PR6424/002-000 | 8mm Eddy Current Sensor with extended range | Power Generation, Robotics |

| Epro PR6423/005-000 | Heavy-duty Eddy Current Sensor | Heavy Machinery Monitoring |

| Epro PR6425/006-000 | Dual Range Eddy Current Sensor | Aerospace, Power Plants |

| Epro PR6423/004-010 | 10mm Compact Eddy Current Sensor | Industrial Automation |

| Epro MMS3120/022-100 | High-precision Displacement Sensor | Automotive, Manufacturing |

| Epro MMS3125/022-020 | Displacement Sensor for industrial environments | Power Generation |

| Epro MMS3160/022-150 | Heavy-duty Displacement Sensor | Robotics, Aerospace |

| Epro MMS3150/022-090 | Process Control Sensor | Process Automation |

Sensor Head DiameterSensor Head DiameterSensor Head DiameterSensor Head DiameterSensor Head Diameter

Popular Models

| Model | Description | Key Features |

|---|---|---|

| Epro MMS3125/022-020 | Displacement Sensor for industrial environments | High-speed response |

| Epro MMS3120/022-100 | High-precision displacement sensor | Compact, Accurate, Robust |

| Epro MMS3160/022-150 | Heavy-duty displacement sensor | Vibration and displacement |

| Epro MMS3150/022-090 | Process control sensor | Analog and digital outputs |

| Epro PR6424/014-040 | Vibration monitoring sensor | Industrial automation |

| Epro PR6423/003-020 | 8mm Eddy Current Sensor | Non-contact measurement |

| Epro PR6423/004-050 | 5mm Eddy Current Sensor | Small parts precision |

| Epro MMS3123/022-100 | Displacement sensor for rotating machinery | Real-time condition monitoring |

| Epro MMS3140/022-050 | Eddy current sensor for process control | Versatile integration |

| Epro PR6423/002-020 | Compact displacement sensor | Low power consumption |

Excellent PLC

Excellent PLC