| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

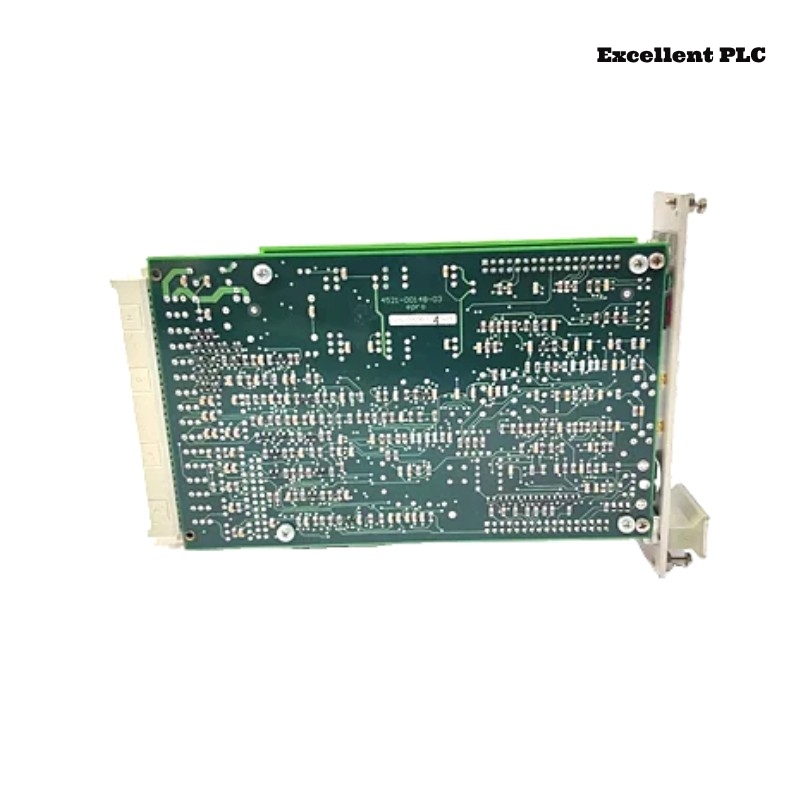

The Epro MMS6410 is a dual-channel measuring amplifier designed for precise vibration and displacement monitoring in industrial applications. It is part of the renowned MMS6000 series, known for its high reliability and accuracy in machinery protection and condition monitoring. The MMS6410 is widely used in industries such as power generation, oil and gas, petrochemicals, and heavy machinery, providing essential data for predictive maintenance and fault diagnostics.

This measuring amplifier processes signals from eddy current sensors, velocity transducers, or acceleration sensors, converting them into a standardized output that can be analyzed for equipment health monitoring. With its modular design, it integrates seamlessly into existing MMS6000 systems, making it an excellent choice for both new installations and system upgrades.

Product Specifications

| Parameter | Specification |

|---|---|

| Number of Channels | 2 (Dual-Channel) |

| Input Signal Types | Eddy current, velocity, acceleration |

| Frequency Range | 0.1 Hz – 10 kHz |

| Output Signal | 4–20 mA, ±10V |

| Power Supply | 24V DC |

| Operating Temperature | -20°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Relative Humidity | 5% to 95% (non-condensing) |

| Dimensions | 30 x 128.4 x 160 mm |

| Weight | 0.32 kg |

| Communication Interface | Modbus, RS485 |

| Housing Protection | IP20 |

| Installation | DIN rail mounting |

| Certification | CE, ATEX (optional for hazardous environments) |

Applications of Epro MMS6410

The MMS6410 dual-channel measuring amplifier is widely applied in machinery protection and predictive maintenance, ensuring safe and efficient operation of industrial assets. Some key application areas include:

- Turbomachinery Monitoring – Used in gas turbines, steam turbines, and compressors to detect early signs of imbalance, misalignment, and wear.

- Rotating Equipment Condition Monitoring – Helps in continuous monitoring of pumps, motors, and gearboxes.

- Vibration Analysis in Heavy Machinery – Supports condition-based maintenance in manufacturing plants.

- Oil & Gas Industry – Essential for monitoring critical rotating equipment in refineries and offshore platforms.

- Power Plants – Ensures smooth operation of generators and steam turbines by monitoring vibration levels.

Advantages of Epro MMS6410

1. Dual-Channel Functionality

- Allows simultaneous monitoring of two independent measurement points, reducing the need for multiple amplifiers.

2. High Sensitivity and Accuracy

- Capable of detecting minor vibrations and displacement changes, providing early warning before serious mechanical failures occur.

3. Modular and Scalable Design

- Fully compatible with Epro MMS6000 monitoring systems, enabling easy system expansion.

4. Flexible Input and Output Options

- Supports various sensor inputs (eddy current, velocity, acceleration), making it adaptable for different industrial applications.

5. Robust and Reliable Performance

- Wide temperature operating range and IP20 housing protection ensure stable operation in harsh environments.

6. Seamless Integration with Control Systems

- Communicates via Modbus and RS485, making it easy to integrate with SCADA, DCS, and PLC systems.

7. Advanced Fault Detection

- Provides real-time diagnostics for quick response to potential machinery faults.

8. Cost-Effective Maintenance

- Helps reduce unplanned downtime and extends equipment lifespan by providing timely alerts.

Latest News About Epro MMS6410

- Epro Introduces Enhanced Diagnostic Features in MMS6410 for Predictive Maintenance

- MMS6410 Now Supports New Sensor Calibration Protocols for Increased Accuracy

- Epro Expands MMS6000 Series with MMS6410 for High-Performance Vibration Monitoring

- MMS6410 Successfully Deployed in Offshore Drilling Platforms for Critical Machinery Protection

- New Firmware Update Released for MMS6410, Enhancing Data Communication Speed

Frequently Asked Questions (FAQ)

-

What type of sensors can be used with the MMS6410 measuring amplifier?

The MMS6410 is compatible with eddy current sensors, velocity transducers, and acceleration sensors, providing flexibility for different monitoring needs. -

Can this amplifier be integrated into existing control systems?

Yes, it supports Modbus and RS485 communication, making it easy to connect with SCADA, DCS, and PLC systems. -

What is the output signal type of the MMS6410?

The module provides 4–20 mA current output and ±10V voltage output, which are widely used in industrial monitoring systems. -

How does the MMS6410 help in predictive maintenance?

By continuously monitoring vibration levels and displacement, the MMS6410 detects anomalies early, preventing unexpected failures. -

What industries benefit from using the MMS6410?

Industries such as power generation, oil & gas, petrochemicals, and heavy machinery rely on the MMS6410 for rotating equipment monitoring. -

Is the MMS6410 resistant to harsh environments?

Yes, it has an IP20 protection rating and can operate in temperatures ranging from -20°C to +70°C. -

Can the MMS6410 monitor two separate machines at the same time?

Yes, as a dual-channel measuring amplifier, it can process signals from two different monitoring points simultaneously. -

What are the installation requirements for this module?

The MMS6410 is designed for DIN rail mounting, making it easy to install within control cabinets. -

Does the MMS6410 support alarm and fault detection?

Yes, it provides real-time diagnostic alerts for vibration anomalies, ensuring fast response to potential failures. -

Is the MMS6410 compatible with legacy Epro systems?

Yes, it integrates seamlessly with the MMS6000 series, allowing upgrades without major system changes.

Recommended Related Models (Same Series or Similar Models)

| Model | Description |

|---|---|

| MMS6110 | Single-channel measuring amplifier |

| MMS6120 | Dual-channel measuring amplifier for displacement sensors |

| MMS6312 | Multi-channel vibration monitoring module |

| MMS6350 | Advanced vibration monitoring system |

| MMS6210 | Universal measuring module for rotating machinery |

| MMS6220 | Vibration monitoring module with extended frequency range |

| MMS6310 | Condition monitoring module for turbomachinery |

| MMS6700 | Advanced vibration analysis module |

| MMS6810 | Dual-channel amplifier for acceleration sensors |

| MMS6900 | High-speed monitoring module for industrial machinery |

Popular Emerson Models in the Same Brand

| Model | Description |

|---|---|

| A6410 | Machinery health monitoring module |

| KJ3002X1-BE1 | Analog output module for process control |

| KJ3243X1-BB1 | Input module for automation systems |

| KJ4001X1-BA2 | High-performance logic controller |

| VE3008 | DeltaV system I/O module |

| KJ3221X1-BA1 | Digital input module for industrial automation |

| KJ4010X1-BG1 | Redundant controller for DeltaV systems |

| 330130-040-00 | Bently Nevada proximity probe module |

| KJ2201X1-PW1 | Power supply module for control systems |

| VE2106 | Industrial communication module |

Excellent PLC

Excellent PLC