| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Protection Introduction

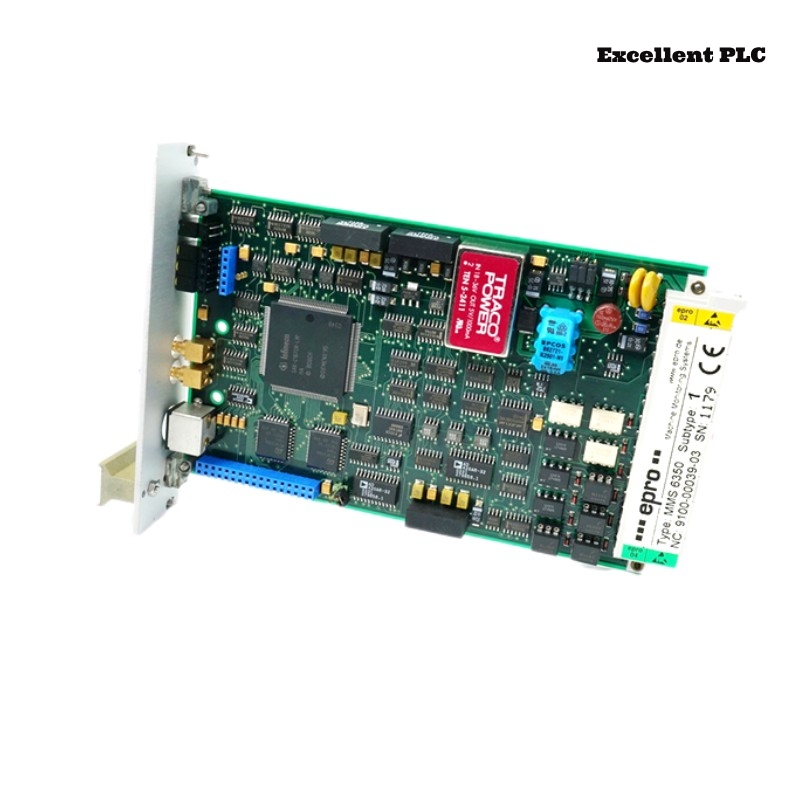

The Epro MMS6350 is a state-of-the-art digital overspeed protection system designed to safeguard rotating machinery from potentially hazardous overspeed conditions. Utilizing a microcontroller-based three-channel measuring system, it offers high reliability and precision in monitoring and controlling machinery speeds. The system is particularly suitable for applications requiring stringent safety standards, as it is certified to SIL3 (Safety Integrity Level 3).

Product Specifications

| Parameter | Details |

|---|---|

| Model | MMS6350 |

| Measurement Channels | 3 (Triple-channel) |

| Input Type | Speed sensors (e.g., eddy current sensors) |

| Measurement Range | 15,000 to 25,000 RPM |

| Accuracy | ±0.1% of full scale |

| Output Signals | 4-20 mA, relay contacts |

| Communication Interface | Optional PROFIBUS-DP |

| Alarm Functions | Up to 6 programmable limit values per channel |

| Operating Voltage | AC 120V / 230V |

| Power Consumption | < 15W |

| Mounting | DIN rail / panel mounting |

| Operating Temperature | -20°C to +70°C |

| Enclosure Rating | IP20 |

| Dimensions (L x W x H) | 30 x 128.4 x 160 mm |

| Weight | 0.32 kg |

Applications

The MMS6350 is widely used in industrial environments where precise speed monitoring and overspeed protection are critical. Common applications include:

- Turbines: Ensuring safe operation in power generation facilities.

- Compressors: Preventing mechanical failures due to overspeed conditions.

- Pumps: Maintaining operational integrity in various industrial processes.

- Generators: Protecting equipment in power plants and industrial settings.

- Motors: Monitoring and controlling speed to prevent damage in manufacturing processes.

Advantages

- High Safety Certification: Achieves SIL3 certification, ensuring compliance with stringent safety standards.

- Triple-Channel Redundancy: Enhances reliability through a three-channel measuring system.

- Programmable Limits: Offers up to six configurable limit values per channel for tailored monitoring.

- Flexible Integration: Optional PROFIBUS-DP interface facilitates seamless communication with control systems.

- User-Friendly Configuration: Microcontroller-based design allows for straightforward setup and operation.

- Compact Design: Optimized dimensions and weight for easy installation in various industrial environments.

Latest News Headlines

- “Epro MMS6350 Sets New Standards in Industrial Overspeed Protection”

- “Integration of MMS6350 with PROFIBUS-DP Enhances System Communication”

- “Achieving SIL3 Certification: The Reliability of Epro’s MMS6350”

- “Case Study: MMS6350 Reduces Downtime in Power Generation Facilities”

- “Epro Introduces Firmware Update for MMS6350, Enhancing Sensor Compatibility”

- “Industry Experts Praise MMS6350 for Advanced Safety Features”

- “MMS6350: A Game Changer in Digital Overspeed Protection Systems”

- “Epro’s Commitment to Safety Highlighted by MMS6350’s Performance”

- “Upcoming Webinar: Implementing MMS6350 for Optimal Machinery Protection”

- “MMS6350 Recognized as Top Overspeed Protection System in Recent Survey”

Frequently Asked Questions (FAQ) for Epro MMS6350 Digital Overspeed Protection System

-

What is the primary purpose of the Epro MMS6350?

- The Epro MMS6350 is a digital overspeed protection system designed to monitor and safeguard rotating machinery from excessive speed conditions, preventing potential damage and ensuring operational safety.

-

How does the MMS6350 detect overspeed conditions?

- It uses a triple-channel measuring system with high-precision speed sensors to continuously monitor rotational speeds. If the speed exceeds predefined limits, the system triggers alarms or shutdown actions.

-

What types of machinery can the MMS6350 be used with?

- It is commonly used with turbines, compressors, pumps, motors, and generators in industries such as power generation, oil and gas, and manufacturing.

-

What communication interfaces does the MMS6350 support?

- The MMS6350 can be equipped with a PROFIBUS-DP interface for seamless integration into industrial control systems.

-

What safety certifications does this device have?

- The MMS6350 is SIL3-certified, ensuring high safety integrity for critical industrial applications.

-

How many programmable speed limit values does the MMS6350 support?

- Each of the three measurement channels supports up to six programmable limit values, allowing for precise speed monitoring and control.

-

Can the MMS6350 be used in harsh industrial environments?

- Yes, it is designed to operate in a wide temperature range of -20°C to +70°C and has an IP20 enclosure rating, making it suitable for industrial settings.

-

What are the mounting options for the MMS6350?

- The device supports DIN rail and panel mounting, offering flexibility in installation.

-

What power supply does the MMS6350 require?

- It operates on AC 120V / 230V power supply with a power consumption of less than 15W.

-

What redundancy features does the MMS6350 offer?

- The triple-channel system provides redundancy in speed measurement, and the system supports redundant power supply configurations for enhanced reliability.

Recommended Models – Same Series or Related Models

| Model | Description | Measurement Type | Safety Level |

|---|---|---|---|

| MMS6312 | Dual-channel rotational speed monitor | Speed Monitoring | SIL2 |

| MMS6350 | Digital overspeed protection system | Overspeed Protection | SIL3 |

| MMS6410 | Vibration and displacement monitor | Vibration Monitoring | SIL3 |

| MMS6620 | Multi-channel temperature monitoring system | Temperature Measurement | SIL2 |

| MMS6820 | Universal condition monitoring module | Condition Monitoring | SIL2 |

| PR6423/002-030+CON021 | Eddy current sensor system for vibration monitoring | Vibration Analysis | SIL3 |

| PR9268/300-000 | Speed sensor for turbo machinery | Speed Measurement | SIL3 |

| CON021 | Signal converter module for PR6423 series sensors | Signal Processing | SIL2 |

| MMS3120 | Machinery protection system for rotating equipment | Machinery Protection | SIL3 |

| MMS6110 | Displacement and shaft vibration monitor | Shaft Monitoring | SIL2 |

Recommended Models – Other Popular Epro Products

| Model | Description | Measurement Type | Safety Level |

|---|---|---|---|

| MMS6120 | Vibration monitoring system for rotating machinery | Vibration Analysis | SIL2 |

| MMS6410 | Advanced displacement and vibration monitor | Displacement Analysis | SIL3 |

| PR6423/010-000 | Eddy current sensor for proximity measurement | Proximity Measurement | SIL2 |

| MMS6250 | Multi-channel machinery condition monitoring | Condition Monitoring | SIL2 |

| PR9376/010-011 | Speed sensor for industrial applications | Speed Detection | SIL3 |

| CON041 | Signal processing module for MMS series sensors | Signal Processing | SIL2 |

| MMS6560 | Overspeed and shutdown monitoring system | Speed & Shutdown | SIL3 |

| MMS6220 | Temperature monitoring system | Temperature Measurement | SIL2 |

| PR9648/200-000 | Industrial speed measurement device | Speed Measurement | SIL2 |

| MMS7120 | Advanced vibration analysis system | Vibration Analysis | SIL3 |

Excellent PLC

Excellent PLC