| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

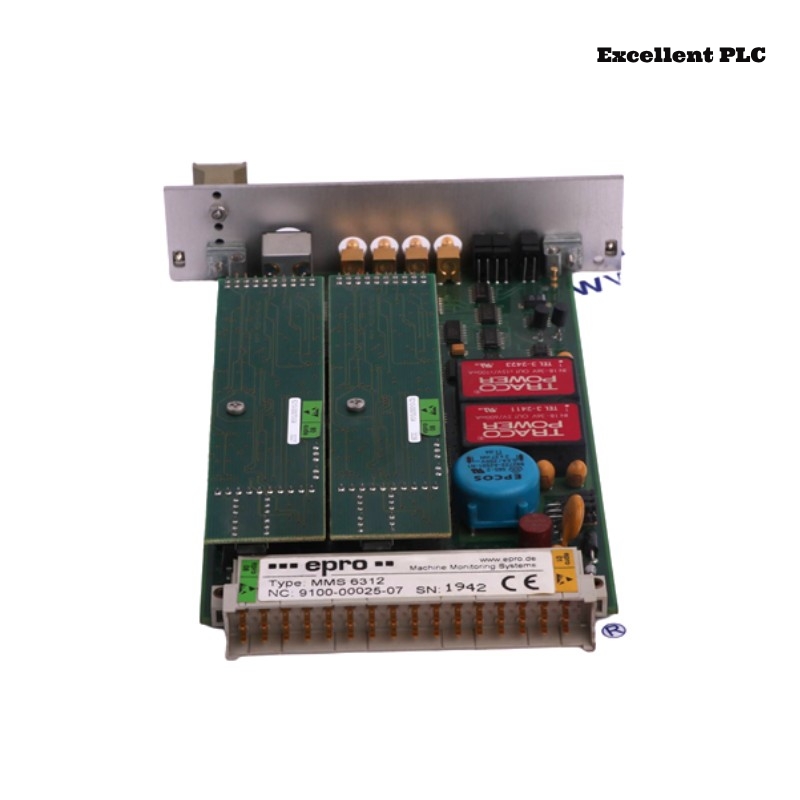

The Epro MMS6312 is a high-precision dual-channel rotational speed monitor designed for real-time monitoring and protection of rotating machinery. It is commonly used in industrial applications where precise speed measurement and safety monitoring are critical, such as turbines, compressors, pumps, and motors. With its dual-channel configuration, it ensures redundancy and reliability, making it ideal for mission-critical processes.

Product Specifications

| Parameter | Details |

|---|---|

| Model | MMS6312 |

| Measurement Channels | 2 (Dual-channel) |

| Input Type | Speed sensors (e.g., proximity probes, magnetic pickups) |

| Measurement Range | 0 – 60,000 RPM |

| Accuracy | ±0.01% of full scale |

| Output Signals | 4-20mA, relay outputs |

| Communication Interface | Modbus, RS485 (optional) |

| Alarm Functions | Programmable high/low-speed limits, overspeed detection |

| Display | LED/LCD Display |

| Operating Voltage | 24V DC / 230V AC (varies by model) |

| Power Consumption | < 10W |

| Mounting | DIN rail / panel mounting |

| Operating Temperature | -20°C to +70°C |

| Enclosure Rating | IP20 |

| Dimensions (L x W x H) | 30 x 128.4 x 160 mm |

| Weight | 0.32 kg |

Applications

The Epro MMS6312 is widely used in industrial automation and process control environments, including:

- Turbomachinery Monitoring – Ensures accurate speed measurement of gas and steam turbines.

- Compressor Systems – Monitors rotational speed to prevent overspeed failures.

- Pumps and Motors – Provides early warnings to prevent mechanical failures.

- Power Plants – Used in thermal and hydroelectric plants for turbine speed monitoring.

- Oil & Gas Industry – Ensures safe operation of rotating equipment in refineries and offshore platforms.

Advantages

- High Precision – Ensures highly accurate speed measurement and monitoring.

- Dual-Channel Design – Provides redundancy for enhanced safety and reliability.

- Programmable Alarms – Enables custom alarm settings for different operating conditions.

- Wide Compatibility – Supports various speed sensors, making integration easier.

- Industrial-Grade Build – Designed to withstand harsh industrial environments.

- Flexible Installation – Supports both DIN rail and panel mounting.

- Communication Interfaces – Supports Modbus and RS485 for remote monitoring.

- User-Friendly Interface – Features an LED/LCD display for real-time status updates.

- Low Power Consumption – Energy-efficient design with minimal power requirements.

Latest News Headlines

- Epro MMS6312 Introduces Enhanced Safety Features for High-Speed Applications

- How Epro MMS6312 is Revolutionizing Rotational Speed Monitoring

- Epro Releases Firmware Update for MMS6312, Improving Sensor Compatibility

- Case Study: MMS6312 Reduces Downtime in Oil Refinery Operations

- MMS6312 Certified for Use in High-Risk Industrial Environments

- Epro Expands Its MMS Series with New Advanced Monitoring Features

- Energy Efficiency in Industrial Monitoring: How MMS6312 Leads the Market

- Experts Recommend MMS6312 for Critical Rotational Speed Monitoring

- Top 5 Rotational Speed Monitors of 2025 – MMS6312 Ranked #1

- Upcoming Webinar: Maximizing Equipment Safety with MMS6312

Frequently Asked Questions (FAQ)

-

What types of sensors are compatible with the MMS6312?

The MMS6312 supports various speed sensors, including proximity probes, magnetic pickups, and optical encoders. -

Can the MMS6312 be integrated into an existing SCADA or DCS system?

Yes, it supports Modbus and RS485 communication for seamless integration. -

What is the advantage of having a dual-channel design?

The dual-channel setup provides redundancy, ensuring continuous monitoring even if one channel fails. -

Does the MMS6312 have programmable alarm thresholds?

Yes, users can set high and low-speed alarm limits, overspeed detection, and warning triggers. -

Is this device suitable for hazardous environments?

The standard version has an IP20 rating, but additional protective enclosures may be needed for hazardous areas. -

How is the MMS6312 powered?

It operates on 24V DC or 230V AC, depending on the model. -

What is the maximum rotational speed it can measure?

The MMS6312 can measure speeds up to 60,000 RPM. -

Does it have relay outputs for external alarms or controls?

Yes, it includes programmable relay outputs for alarms, trip signals, or interlocks. -

Can the MMS6312 store historical data?

No, it does not have onboard storage, but it can send data to a SCADA system or data logger. -

What power supply options are available for this module?

The MMS6312 operates on 24V DC or 230V AC, depending on the model configuration.

Recommended Related Models (Same Series or Similar Functionality)

| Model Number | Description |

|---|---|

| MMS6210 | Single-Channel Rotational Speed Monitor |

| MMS6410 | Multi-Channel Rotational Speed and Vibration Monitor |

| MMS6350 | Speed and Overspeed Protection Monitor |

| MMS6620 | Dual-Channel Condition Monitoring Module |

| MMS6200 | Speed Measurement Module for Low-Speed Applications |

| MMS6450 | Advanced Machinery Protection System |

| MMS6600 | High-Speed Rotational Monitoring System |

| MMS6700 | Speed and Acceleration Monitoring Module |

| MMS6150 | Compact Rotational Speed Monitoring Device |

| MMS6900 | Digital Speed and Overspeed Monitoring System |

Popular Epro Models (Same Brand, Different Functionality)

| Model Number | Description |

|---|---|

| PR6423/000-000 | Eddy Current Sensor for Vibration Monitoring |

| PR6424/014-040 | High-Temperature Vibration Sensor |

| PR9268/203-000 | Accelerometer for Machinery Monitoring |

| CON021 | Signal Converter for Proximity Probes |

| PR6425/000-031 | Industrial Vibration Sensor |

| PR6426/000-030 | Displacement Sensor for Rotating Equipment |

| PR6427/010-110 | Velocity Sensor for Turbomachinery |

| PR6428/016-110 | Precision Speed and Vibration Sensor |

| PR9268/302-000 | Piezoelectric Vibration Sensor |

| MMS3110 | Universal Monitoring Module for Industrial Equipment |

Excellent PLC

Excellent PLC