| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

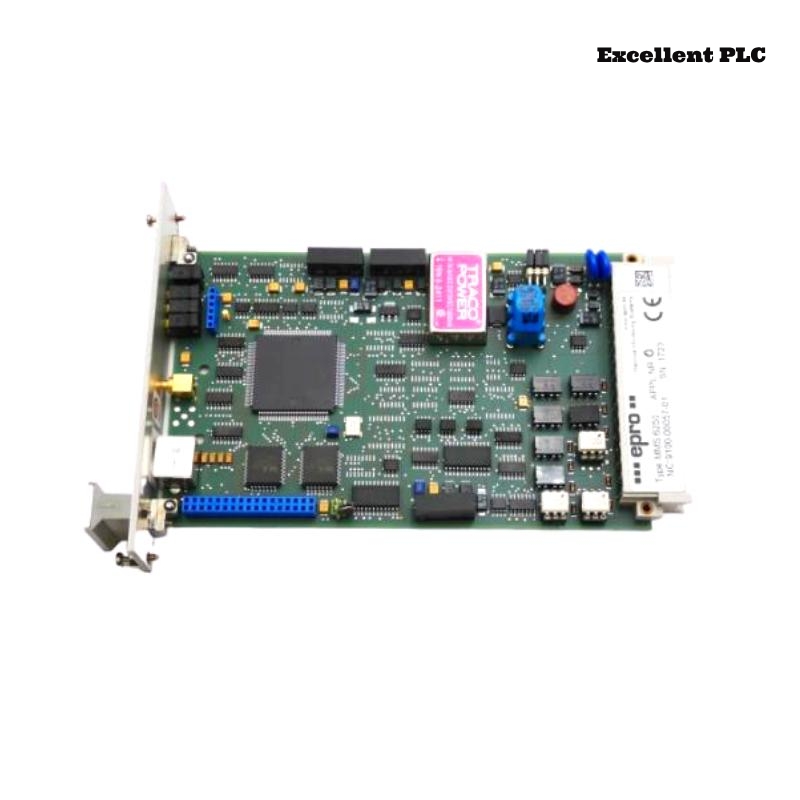

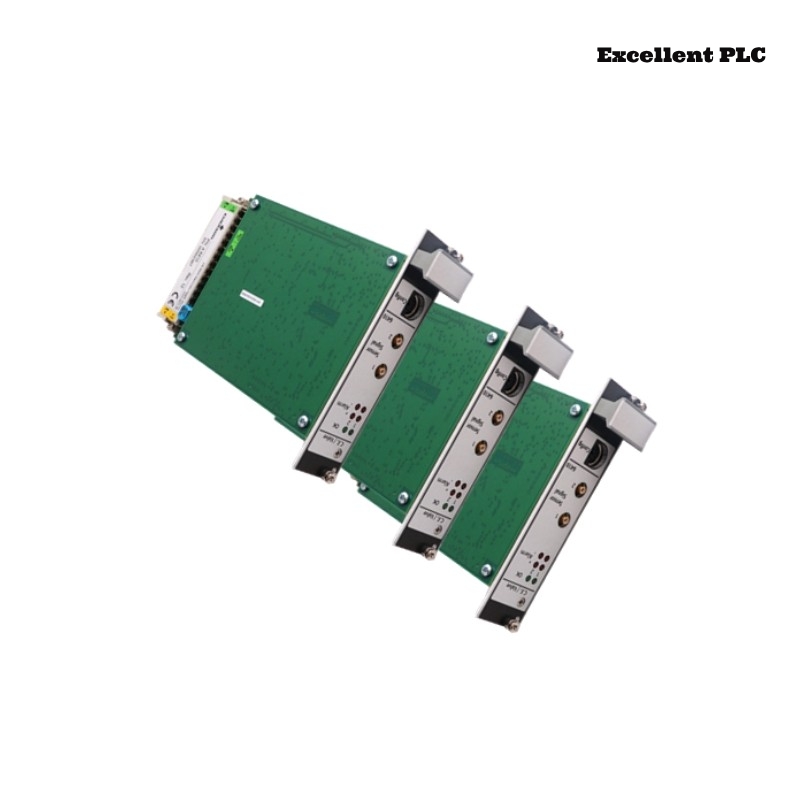

Product Overview: Epro MMS6250 9100-00057 Digital Axial Protection System Shaft Displacement Monitor

The Epro MMS6250 9100-00057 is a digital axial protection system designed to monitor shaft displacement in industrial rotating machinery. This system provides high-precision measurement and real-time protection to prevent excessive axial movement, which can lead to mechanical failures and costly downtime.

The MMS6250 is an essential component in turbines, compressors, pumps, and generators, where accurate shaft displacement monitoring is crucial for operational reliability and safety. This advanced system is engineered for seamless integration with condition monitoring and predictive maintenance systems, ensuring long-term equipment health.

With its robust digital signal processing (DSP) capabilities, the MMS6250 delivers precise measurement, alarm triggering, and real-time data analysis. It is fully compatible with Epro’s MMS series monitoring modules and supports industry-standard communication protocols for easy integration into SCADA, DCS, and PLC systems.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | MMS6250 9100-00057 |

| Measurement Type | Digital Axial Shaft Displacement Monitoring |

| Input Signal | Supports Proximity Probes and Displacement Sensors |

| Measurement Range | ±0.5 mm to ±10 mm (Adjustable) |

| Resolution | 0.001 mm |

| Accuracy | ±1% of Full-Scale Reading |

| Signal Processing | Digital Signal Processing (DSP) |

| Alarm Settings | Programmable Alarm & Shutdown Thresholds |

| Outputs | 4-20mA Analog, Relay Outputs, RS485 (Modbus) |

| Communication Protocols | Modbus RTU, TCP/IP, HART, Profibus |

| Power Supply | 24V DC / 110V-240V AC |

| Operating Temperature | -20°C to +70°C |

| Humidity Range | 5% – 95% RH (Non-Condensing) |

| Display | LED/LCD Display with Status Indicators |

| Mounting Type | DIN Rail or Panel Mount |

| Enclosure Rating | IP65 (Dust and Water Resistant) |

| Weight | 0.32 kg |

| Dimensions (H x W x D) | 30 x 128.4 x 160 mm |

| Compliance | CE, ATEX, IECEx, RoHS |

Applications

The Epro MMS6250 is used in a variety of industrial sectors, ensuring machinery safety and optimal performance:

- Power Generation – Steam turbines and gas turbines in power plants require precise axial displacement monitoring to avoid unplanned shutdowns.

- Oil & Gas – Used in compressors and pumps in refineries to ensure equipment safety and efficiency.

- Chemical Processing – Protects critical rotating machinery in chemical and petrochemical plants.

- Steel and Mining – Applied in heavy-duty industrial machinery where shaft misalignment can cause catastrophic failures.

- Marine & Aerospace – Ensures safe and efficient operation of propulsion systems and turbomachinery.

Advantages

- High Precision Measurement – Provides real-time, accurate shaft displacement monitoring to prevent excessive axial movement.

- Advanced Digital Signal Processing (DSP) – Ensures fast response times and reliable data analysis.

- Programmable Alarms & Shutdowns – Customizable alarm levels to protect machinery from unexpected failures.

- Multi-Sensor Compatibility – Supports various proximity probes and displacement sensors for flexibility.

- Multiple Communication Interfaces – Supports Modbus, HART, and Profibus for seamless integration with SCADA/DCS/PLC.

- User-Friendly Interface – Features an intuitive display and LED indicators for easy monitoring and configuration.

- Robust Industrial Design – Built with IP65-rated enclosure for dust and water resistance in harsh environments.

- Flexible Mounting Options – Supports DIN rail or panel mounting for convenient installation.

- Low Power Consumption – Designed for efficient energy usage while maintaining high performance.

- Compliance with International Standards – Certified for CE, ATEX, IECEx, and RoHS, ensuring global safety compliance.

Latest News

Epro Enhances MMS6250 Series with AI-Based Predictive Maintenance Capabilities

Epro recently announced AI-driven enhancements for the MMS6250 series, allowing real-time predictive maintenance analytics. These new features utilize machine learning algorithms to detect early warning signs of shaft misalignment and wear, enabling proactive maintenance scheduling.

In addition, Epro has expanded remote monitoring capabilities, allowing plant operators to access shaft displacement data via cloud-based dashboards. This enhancement improves operational efficiency and reduces downtime risks.

Frequently Asked Questions (FAQ)

-

What is the primary function of the MMS6250 9100-00057?

- It is used for monitoring and protecting rotating machinery by detecting axial shaft displacement.

-

What types of sensors are compatible with this system?

- It supports proximity probes and displacement sensors from various manufacturers.

-

What communication protocols does the MMS6250 support?

- It supports Modbus RTU, Modbus TCP/IP, HART, and Profibus for integration with SCADA/DCS/PLC systems.

-

How accurate is the MMS6250 in detecting shaft displacement?

- It provides ±1% full-scale accuracy with 0.001 mm resolution.

-

Can the MMS6250 be used in hazardous environments?

- Yes, it is ATEX and IECEx certified for use in explosive atmospheres.

-

What is the power supply requirement for this system?

- It operates on 24V DC or 110V-240V AC, making it suitable for different industrial setups.

-

Does the MMS6250 have remote monitoring capabilities?

- Yes, it can be accessed remotely via Ethernet-based Modbus TCP/IP.

-

Is the system easy to install and configure?

- Yes, it offers DIN rail or panel mounting and a user-friendly interface for quick setup.

-

What industries commonly use the MMS6250?

- It is widely used in power plants, oil & gas refineries, chemical plants, and manufacturing facilities.

-

What maintenance is required for the MMS6250?

- Regular calibration and sensor inspections ensure optimal performance.

Recommended Related Models from the Same Series

| Model Number | Description |

|---|---|

| MMS6110 | Vibration Monitoring Module |

| MMS6120 | Velocity and Displacement Monitor |

| MMS6140 | Temperature Monitoring System |

| MMS6150 | Speed and Acceleration Monitor |

| MMS6160 | Multi-Channel Condition Monitoring Module |

| MMS6210 | Rotor Vibration Monitoring System |

| MMS6220 | Machine Protection System |

| MMS6230 | Overspeed Protection System |

| MMS6240 | Digital Bearing Condition Monitoring |

| MMS6260 | Advanced Condition Monitoring Analyzer |

Popular Models from Epro

| Model Number | Description |

|---|---|

| PR6423/000-010 | Proximity Probe for Shaft Vibration |

| PR6424/014-040 | High-Precision Displacement Sensor |

| PR9268/300-000 | Temperature Sensor for Rotating Machinery |

| CON021 | Proximity Probe Converter Module |

| MMS6312 | Turbine Supervisory System |

| MMS6350 | Multi-Channel Machine Protection System |

| MMS6410 | Advanced Diagnostic Module |

| MMS6500 | High-Speed Data Acquisition Module |

| MMS6800 | Wireless Condition Monitoring Solution |

| MMS6900 | Portable Vibration Analyzer |

Excellent PLC

Excellent PLC