| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

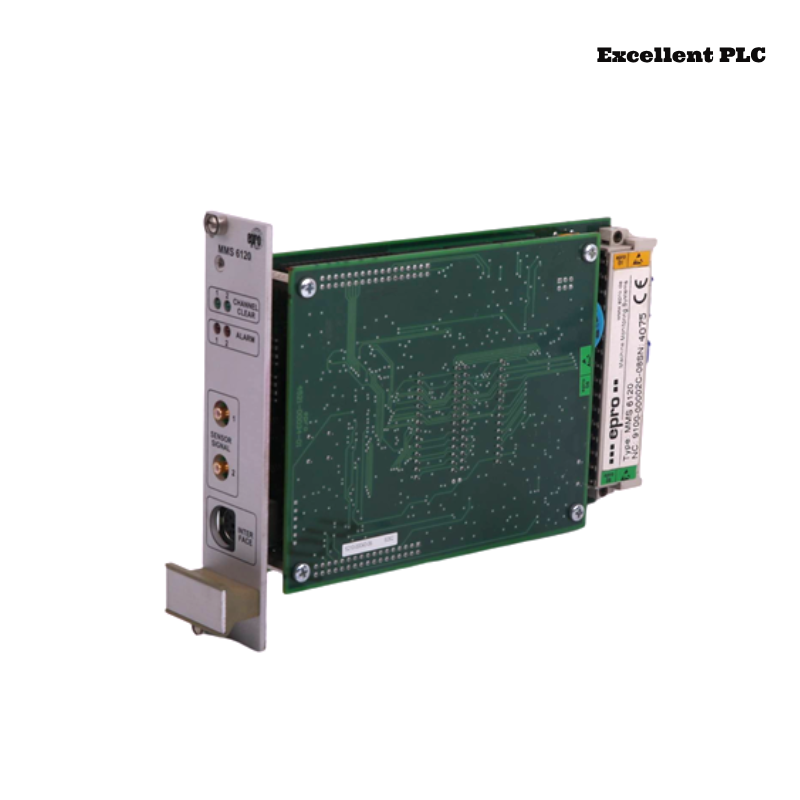

Product Overview

The Epro MMS6120 9100-00002-10 is a dual-channel bearing vibration monitor designed for continuous monitoring of machinery health, specifically aimed at bearing vibration detection. This product is used to safeguard critical machinery components by detecting early signs of wear, imbalance, or misalignment, allowing for preventative maintenance and reducing the risk of unexpected downtime. The unit offers high reliability and is well-suited for industries that demand precise, real-time monitoring of rotating equipment, such as power plants, oil and gas, and manufacturing facilities.

Product Specifications

The following table outlines the key specifications of the Epro MMS6120 9100-00002-10 Dual Channel Bearing Vibration Monitor:

| Parameter | Specification |

|---|---|

| Input Channels | 2 Channels (Dual Channel) |

| Vibration Measurement Range | 0.1 to 5000 Hz |

| Power Supply | 24 V DC ± 20% |

| Output Signal | 4-20 mA (current output for each channel) |

| Alarm Outputs | 2 relay outputs for alarm and warning |

| Communication Interface | Modbus RTU (RS485) |

| Operating Temperature | -20°C to +60°C (-4°F to +140°F) |

| Humidity | 5% to 95% RH (non-condensing) |

| Dimensions | 30 x 128.4 x 160 mm |

| Weight | 0.32 kg |

| Mounting | Wall or panel mountable |

| Environmental Protection | IP65 (dust-tight and water-resistant) |

| Display Type | Optional (external display unit) |

| Certification | CE, UL, RoHS |

Product Applications

The Epro MMS6120 is ideal for use in environments where the health of rotating machinery is critical to operation. Some key applications include:

- Power Generation: Monitoring turbines, pumps, and compressors for vibration abnormalities.

- Oil and Gas Industry: Ensuring the safety and efficiency of drilling equipment and pumping stations.

- Manufacturing: Protecting industrial machines like motors, conveyors, and presses from excessive vibration.

- Water Treatment: Monitoring pumps, fans, and motors in treatment facilities to avoid mechanical failures.

- Mining: Detecting early signs of bearing failure in crushers, mills, and conveyors to reduce unplanned downtime.

Product Advantages

The Epro MMS6120 9100-00002-10 offers a range of advantages that make it an excellent choice for critical machinery protection:

- Dual Channel Monitoring: The dual channel design allows simultaneous monitoring of two independent bearing locations, enhancing the system’s flexibility.

- Real-time Vibration Analysis: Provides continuous and real-time feedback on vibration levels, offering insights into the operational health of machinery.

- Prevention of Unplanned Downtime: Early detection of bearing faults such as imbalance, misalignment, or excessive wear reduces the risk of catastrophic failure.

- Modbus RTU Communication: Easily integrates into existing systems for remote monitoring and control via standard communication protocols.

- Compact and Robust Design: The compact form factor and IP65 rating make it suitable for harsh industrial environments.

- Low Maintenance: Designed for minimal maintenance while offering reliable performance over extended periods.

- Cost-effective: By detecting potential failures before they become critical, the monitor helps reduce maintenance and repair costs, improving overall equipment efficiency.

Recent Product News

The Epro MMS6120 9100-00002-10 is part of the broader trend in the industry toward more sophisticated and reliable machinery protection systems. Epro continues to innovate in vibration monitoring technology, helping companies reduce costs and improve operational efficiency.

Frequently Asked Questions (FAQs)

-

What types of machinery can the Epro MMS6120 monitor?

- It is designed to monitor bearing vibrations in various industrial machinery, including motors, pumps, compressors, and turbines.

-

How does the system alert users to potential problems?

- The monitor has relay outputs for alarm and warning signals, which can be connected to an external system to alert operators.

-

What kind of output signal does the Epro MMS6120 provide?

- It provides a 4-20 mA current output for each channel, which can be used for further analysis and monitoring.

-

Can the monitor communicate with other control systems?

- Yes, the Epro MMS6120 uses Modbus RTU (RS485) communication to integrate easily with other industrial systems.

-

What is the operating temperature range of the monitor?

- The device can operate in temperatures ranging from -20°C to +60°C (-4°F to +140°F).

-

Is the Epro MMS6120 suitable for use in harsh environments?

- Yes, it has an IP65 rating, making it dust-tight and resistant to water, ideal for harsh industrial settings.

-

What is the power supply requirement for the unit?

- The monitor requires a 24 V DC power supply, with a tolerance of ±20%.

-

Can this unit be used in multiple channels simultaneously?

- Yes, the Epro MMS6120 has two channels for monitoring two independent bearing locations.

-

How does the vibration range of 0.1 to 5000 Hz benefit the user?

- This wide frequency range allows the monitor to detect various vibration abnormalities, from low-frequency bearing issues to high-frequency mechanical faults.

-

What are the typical applications of the Epro MMS6120?

- The device is commonly used in power generation, oil and gas, manufacturing, water treatment, and mining industries.

Related Models in the Same Series or Category

| Model | Description |

|---|---|

| Epro MMS6120 9100-00002-20 | Enhanced version with additional features for more complex machinery monitoring. |

| Epro MMS6120 9100-00001-10 | Single-channel version for simpler monitoring needs. |

| Epro MMS6200 | Advanced vibration monitor with additional diagnostic capabilities for critical machinery. |

| Epro MMS6200-2 | Dual-channel version offering higher flexibility and additional data analysis options. |

| Epro MMS6350 | Multi-axis vibration monitor designed for large-scale turbines and compressors. |

| Epro MMS6250 | Compact vibration sensor ideal for smaller rotating equipment in industrial applications. |

| Epro MMS6310 | Portable version designed for on-site diagnostics and vibration measurement. |

| Epro MMS6340 | System designed for multi-point vibration monitoring, used in complex plant operations. |

| Epro MMS6300 | Standard vibration monitoring system, suitable for a variety of industrial machinery. |

| Epro MMS6190 | Vibration monitor for use in highly sensitive applications requiring high precision analysis. |

Popular Models from Epro

| Model | Description |

|---|---|

| Epro MMS6240 | Compact vibration monitor for continuous operation and preventive maintenance. |

| Epro MMS6500 | High-end machinery monitoring system offering comprehensive diagnostics and analysis. |

| Epro MMS6230 | Vibration analysis system with real-time fault detection and performance monitoring. |

| Epro MMS6600 | Advanced monitoring system providing multi-sensor integration for critical equipment protection. |

| Epro MMS6300 | Reliable, cost-effective vibration monitor designed for small to medium-sized industrial machinery. |

| Epro MMS6280 | High-precision monitor used in high-speed equipment, including turbines and large compressors. |

| Epro MMS6050 | Entry-level vibration monitor with essential features for small-scale applications. |

| Epro MMS6220 | Modular vibration monitoring system with scalable options for complex systems. |

| Epro MMS6100 | Basic vibration monitor for single-axis measurement and low-cost vibration monitoring solutions. |

| Epro MMS6400 | Advanced vibration monitor for turbines, engines, and other high-precision machinery. |

Excellent PLC

Excellent PLC