| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

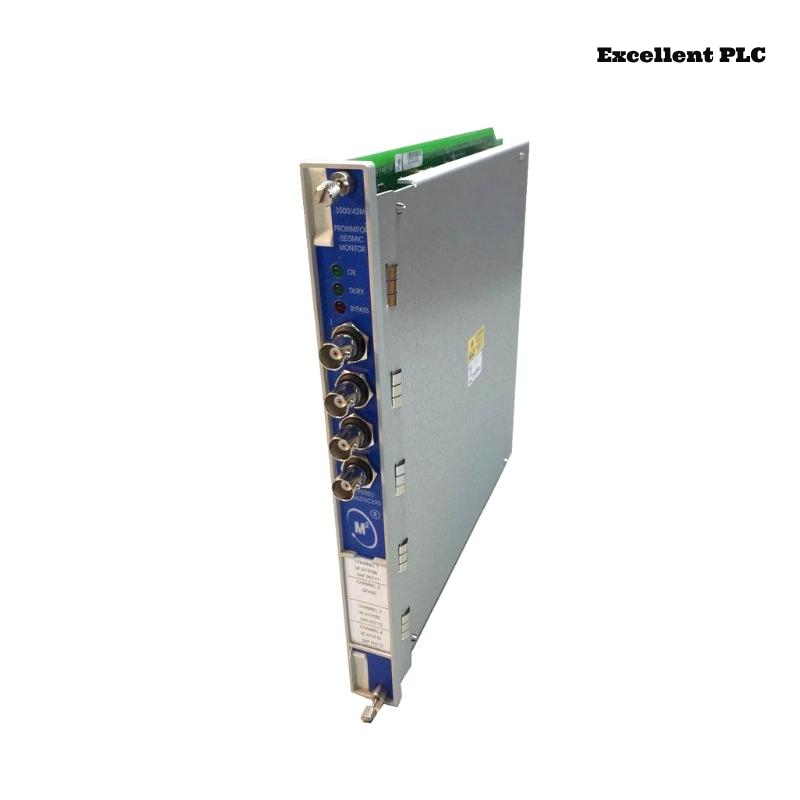

Product Overview

| Specification | Details |

|---|---|

| Product Number | 176449-02 |

| Module Type | Proximitor/Seismic Monitor |

| Channels | 4 |

| Input Types | Proximity and seismic transducers |

| Functions | Radial Vibration, Thrust Position, Differential Expansion, Eccentricity, Acceleration, Velocity, Shaft Absolute, Circular Acceptance Region |

| Power Consumption | 7.7 W |

| Input Impedance | 10 kΩ (standard I/O) |

| Dimensions (D x W x H) | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

| Compliance | CE, CSA, ATEX, IECEx |

| Operating Temperature Range | -30°C to +65°C |

| Storage Temperature Range | -40°C to +85°C |

| Humidity | 0% to 95% non-condensing |

| Mounting | 3500 rack system |

Product Applications

The Bently Nevada 3500/42M 176449-02 Proximitor Seismic Monitor is utilized across various industries for critical machinery protection and condition monitoring. Key applications include:

-

Rotating Machinery Monitoring: Ensures the operational integrity of turbines, compressors, pumps, and motors by continuously measuring vibration and position parameters.

-

Seismic Event Detection: Monitors structural vibrations to detect seismic events, safeguarding equipment from potential damage.

-

Thrust Position Measurement: Tracks axial displacement in machinery to prevent contact between stationary and rotating components.

-

Differential Expansion Monitoring: Measures the relative expansion between rotors and casings in turbines, preventing mechanical interference.

-

Eccentricity Measurement: Assesses shaft bow or misalignment to maintain optimal machinery performance.

Product Advantages

The 3500/42M Proximitor Seismic Monitor offers several benefits that enhance machinery protection and operational efficiency:

-

Comprehensive Monitoring: Supports multiple measurement types, including vibration, position, and acceleration, providing a holistic view of machinery health.

-

User-Programmable Alarms: Allows customization of alarm thresholds for each channel, enabling tailored responses to specific operational requirements.

-

High Reliability: Designed for continuous operation in demanding industrial environments, ensuring consistent machinery protection.

-

Scalability: Easily integrates into existing 3500 rack systems, facilitating expansion as monitoring needs grow.

-

Regulatory Compliance: Meets international standards such as CE, CSA, ATEX, and IECEx, ensuring adherence to global safety and performance requirements.

Recent News

Recent developments related to the Bently Nevada 3500/42M 176449-02 Proximitor Seismic Monitor include:

-

Bently Nevada Enhances 3500 Series with Advanced Monitoring Capabilities: A recent update highlights the integration of advanced diagnostics in the 3500 series, improving machinery health assessment.

-

New Firmware Release for 3500/42M Monitor: The latest firmware update introduces enhanced data processing algorithms, increasing the accuracy of vibration and position measurements.

-

Industry Adoption of 3500/42M in Renewable Energy Sector: The renewable energy industry has adopted the 3500/42M monitor for wind turbine condition monitoring, ensuring efficient and reliable operations.

Frequently Asked Questions (FAQs)

-

What transducers are compatible with the 3500/42M monitor?

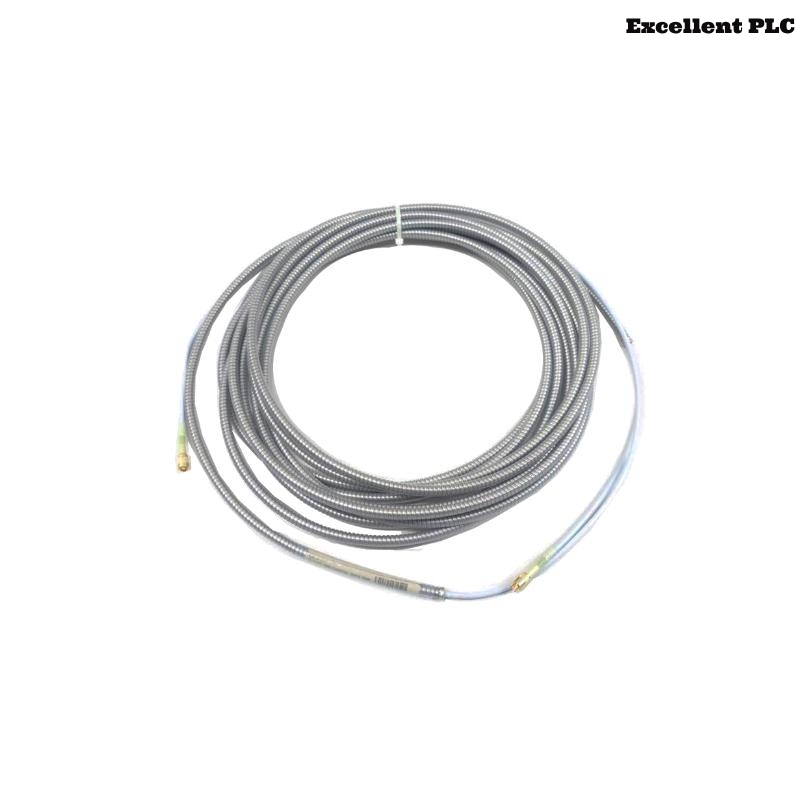

- The monitor is compatible with Bently Nevada proximity and seismic transducers, including Proximitor sensors, accelerometers, and velocity sensors.

-

Can the alarm thresholds be customized?

- Yes, each channel’s alarm setpoints are user-programmable to accommodate specific operational requirements.

-

Is the 3500/42M monitor suitable for hazardous environments?

- Yes, it complies with certifications such as ATEX and IECEx, making it suitable for use in hazardous locations.

-

How does the monitor integrate with existing control systems?

- The 3500/42M monitor integrates seamlessly with Bently Nevada’s 3500 rack systems and can communicate with plant control systems via standard protocols.

-

What diagnostic features does the monitor offer?

- It includes self-testing and fault detection capabilities to ensure continuous and reliable operation.

-

Is field calibration possible for the 3500/42M monitor?

- Yes, the monitor supports field calibration procedures to maintain measurement accuracy over time.

-

What is the power consumption of the monitor?

- The 3500/42M monitor has a power consumption of 7.7 W.

-

Can the monitor’s firmware be upgraded?

- Yes, the firmware is field-upgradable, allowing for enhancements and new features to be added as they become available.

-

What are the operating temperature limits for the monitor?

- The monitor operates effectively within a temperature range of -30°C to +65°C.

-

Does the monitor support remote monitoring?

- Yes, it supports remote monitoring capabilities through network interfaces, enabling off-site data access and analysis.

Related Models

Here are 10 related models within the same series or with similar functionalities:

| Model Number | Description |

|---|---|

| 3500/40M | Proximitor Monitor |

| 3500/44M | Aeroderivative GT Vibration Monitor |

| 3500/45 | Position Monitor |

| 3500/46M | Hydro Monitor |

| 3500/50 | Tachometer Module |

| 3500/60 | Temperature Monitor |

| 3500/64M | Dynamic Pressure Monitor |

| 3500/65 | Velocity Monitor |

| 3500/70M | Recip Rod Position Monitor |

| 3500/72M | Recip Impulse Velocity Monitor |

10 popular models from Bently Nevada:

| Model Number | Description |

|---|---|

| 3300/16 | Dual Vibration Monitor |

| 3300/20 | Dual Thrust Position Monitor |

| 3300/25 | Keyphasor Module |

| 3300/35 | Temperature Monitor |

| 3300/40 | Proximitor Monitor |

| 3300/50 | Tachometer Module |

| 3300/60 | Process Variable Monitor |

| 3300/65 | Velocity Monitor |

| 3300/70 | Recip Rod Position Monitor |

| 3300/80 | Recip Cylinder Pressure Monitor |

Excellent PLC

Excellent PLC