| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

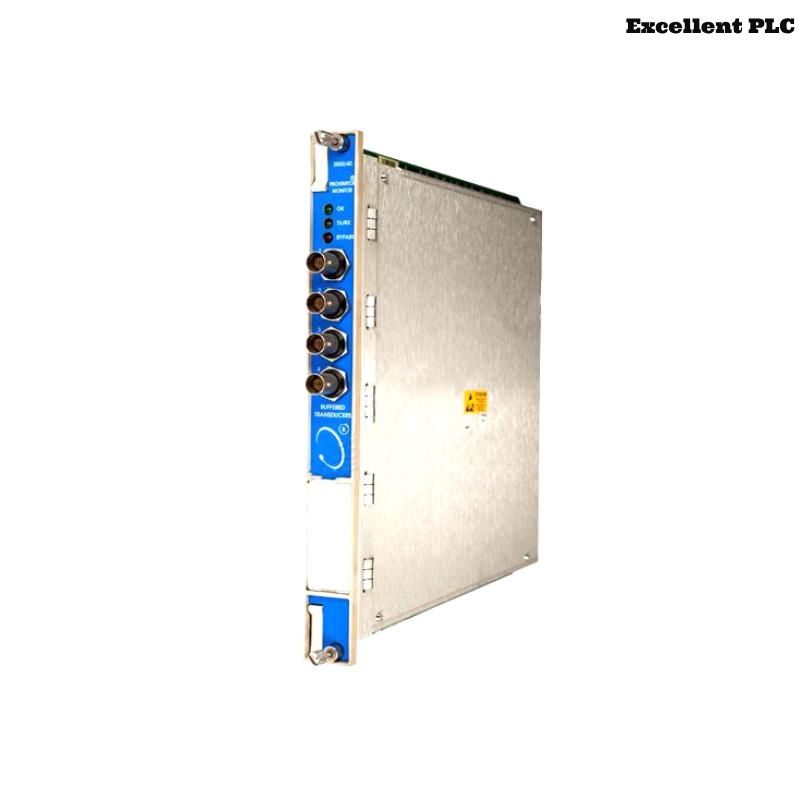

The Bently Nevada 3500/40-01-00 Proximitor Monitor is a four-channel module designed to interface with Bently Nevada proximity transducers. It conditions input signals to provide various vibration and position measurements, comparing them with user-defined alarms. Each channel can be configured for functions such as radial vibration, thrust position, differential expansion, and eccentricity, making it a versatile component in machinery protection systems.

Product Specifications

| Parameter | Details |

| Model Number | 3500/40-01-00 (3500/40M) |

| Channels | 4 independent channels |

| Input Type | Bently Nevada proximity transducers |

| Output Impedance | 550 Ω |

| Transducer Power Supply | -24 VDC |

| Alarm Setpoints | User-programmable for each channel |

| Operating Temperature | -30°C to +65°C (-22°F to +150°F) |

| Storage Temperature | -40°C to +85°C (-40°F to +185°F) |

| Humidity Range | 0% to 95% non-condensing |

| Certifications | CE, CSA, ATEX, IECEx, GOST |

| Dimensions | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

Product Applications

-

Machinery Protection Systems: Monitors critical parameters in turbines, compressors, and pumps.

-

Process Control Integration: Interfaces with DCS and PLC systems for comprehensive process monitoring.

-

Safety Systems: Implements voting logic for critical safety applications requiring high reliability.

-

Industrial Automation: Used in various industries including oil and gas, power generation, and manufacturing for equipment protection.

Product Advantages

-

Flexible Configuration: Each channel can be independently programmed for specific monitoring functions.

-

High Reliability: Designed for long operational life with robust construction.

-

Seamless Integration: Easily integrates into existing 3500 rack systems without additional hardware.

-

Global Certifications: Meets international standards for use in hazardous environments.

Frequently Asked Questions (FAQ)

-

What is the function of the 3500/40M module?

-

It provides four channels for monitoring vibration and position parameters in machinery protection systems.

-

-

Can each channel be configured independently?

-

Yes, each channel can be programmed separately for specific monitoring functions.

-

-

What types of measurements can the module perform?

-

It can measure radial vibration, thrust position, differential expansion, and eccentricity.

-

-

Is the module compatible with hazardous environments?

-

Yes, it has certifications including ATEX, CSA, IECEx, and GOST for use in hazardous areas.

-

-

Where is the module installed in the 3500 rack?

-

It occupies one full-height front slot and requires a corresponding I/O module in the rear slot.

-

-

What is the power supply requirement for the transducers?

-

The module provides a -24 VDC power supply for the transducers.

-

-

What is the output impedance of the module?

-

The output impedance is 550 Ω.

-

-

What is the operational temperature range?

-

The module operates between -30°C and +65°C (-22°F to +150°F).

-

-

Can the module be used in redundant configurations?

-

Yes, multiple modules can be used to provide redundancy in critical applications.

-

-

Is the module compatible with all 3500 series systems?

-

Yes, it is designed to integrate seamlessly with the entire 3500 series.

-

Related Models from the Same Series (Bently Nevada 3500 Series)

| Model Number | Description | Main Function |

| 3500/42M | Proximitor/Seismic Monitor | Monitors radial vibration, thrust, and seismic signals. |

| 3500/44M | Aeroderivative GT Vibration Monitor | Specialized for aeroderivative gas turbines; supports proximity and velocity sensors. |

| 3500/50 | Tachometer Module | Measures shaft speed and calculates zero speed and reverse rotation. |

| 3500/60 | Temperature Monitor | Interfaces with RTDs and thermocouples for temperature measurements. |

| 3500/64M | Dynamic Pressure Monitor | Measures dynamic pressure in combustion chambers, bearings, etc. |

| 3500/22M | Transient Data Interface (TDI) | Collects dynamic waveform and trend data, enabling condition monitoring. |

Popular Bently Nevada Models (Across Different Systems)

| Model Number | Description | Main Function |

| 3300 XL | Proximity Transducer System | Measures shaft position, vibration; used for rotating equipment monitoring. |

| 1900/65A | General Purpose Vibration Monitor | Compact two-channel vibration monitor for simple machinery monitoring. |

| 2300/20 | Balance-of-Plant Equipment Monitor | Low-cost protection for pumps, motors, fans, and other auxiliary equipment. |

| 3701/40 | Machinery Protection System | Compact system for critical equipment; high-performance condition monitoring. |

| 3500/25 | Keyphasor Module | Provides timing reference (phase) for vibration and speed analysis. |

| 3500/33 | 16-Channel Relay Module | Offers relay output capability for alarms and shutdown logic. |

Excellent PLC

Excellent PLC