| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

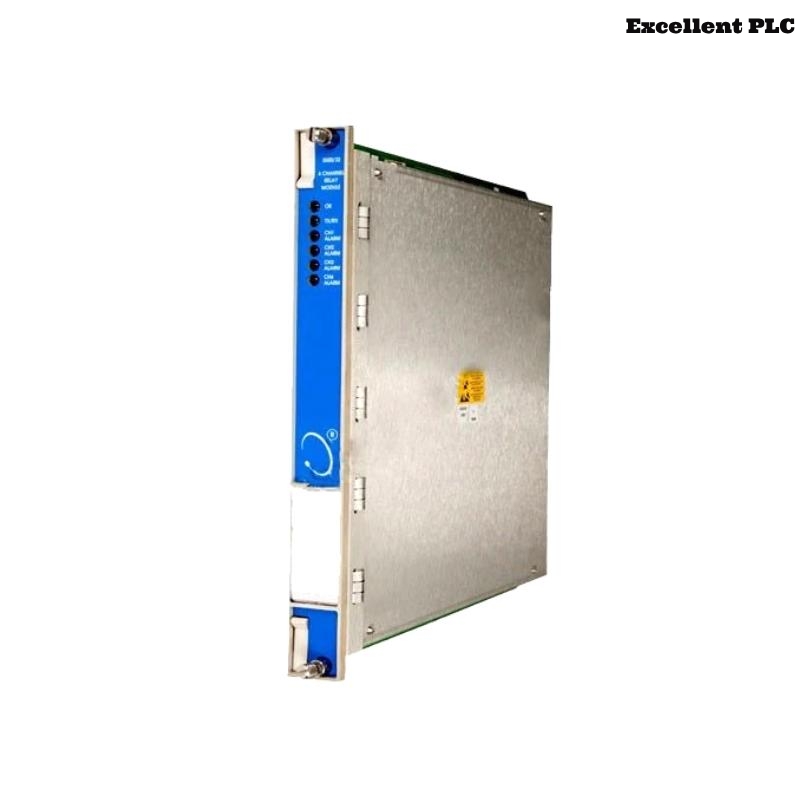

The Bently Nevada 3500/32-01-00 is a high-reliability 4-Channel Relay Module, purpose-built to deliver alarm and shutdown logic in the 3500 Series Machinery Protection System. Acting as a critical interface between the monitoring system and external equipment, the module provides user-configurable relays that respond to system alarms, operating conditions, or user-defined logic.

Each relay channel is completely independent and software-configurable through the 3500 System Configuration Software. This module is essential for integrating machine protection functions with broader plant control systems such as Distributed Control Systems (DCS), Programmable Logic Controllers (PLC), or Safety Instrumented Systems (SIS).

Product Specifications

| Parameter | Details |

| Model Number | 3500/32-01-00 |

| Description | 4-Channel Relay Module |

| Channels | 4 independent relays |

| Relay Type | Electromechanical SPDT (Single Pole Double Throw) relays |

| Contact Ratings | 5 A @ 24 VDC / 250 VAC resistive |

| Contact Life | 10⁶ operations minimum (resistive load) |

| Relay Energization | User-configurable (energized or de-energized) |

| Latch Functionality | Yes (software-configurable) |

| Alarm Conditions Supported | OK, NOT OK, ALERT, DANGER, System Events |

| Position in Rack | Requires adjacent Relay I/O Module in the rack |

| Power Consumption | < 6 Watts |

| Redundancy Support | Yes (in combination with dual modules) |

| Operating Temperature | -30°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 0% to 95% RH, non-condensing |

| Certifications | CE, CSA, ATEX, IECEx, GOST |

| Dimensions (H × W × D) | 241 x 24.4 x 242 mm |

| Weight | 0.7 kg |

Product Applications

-

Turbomachinery Shutdown Systems: Provides critical trip outputs for steam turbines, gas turbines, and compressors.

-

Alarm Indication: Visual and audible alarms triggered through external devices via relays.

-

Process Automation Integration: Connects with DCS and SIS systems to share machine state and fault status.

-

Emergency Interlocks: Links machinery faults with plant-wide emergency shutdown sequences.

-

Industrial Machinery Protection: Commonly applied in oil & gas, petrochemical, power generation, and mining operations.

Product Advantages

-

Flexible Relay Configuration: Each relay channel can be individually assigned to specific alarms or logical conditions.

-

Failsafe Design: Supports both energized and de-energized relay operation for safety-critical systems.

-

High Endurance: Mechanical design ensures reliable performance across millions of operations.

-

Compact & Scalable: Slim profile integrates seamlessly into 3500 racks without consuming excess space.

-

Reliable Isolation: Electrical isolation between channels minimizes interference and cross-talk.

-

Logic-Driven Output: Can be tied to AND/OR logic in system configuration for advanced control strategies.

-

Redundant Operation: Works in redundant pairs to ensure continuous relay function during failures.

-

Certification Ready: Suitable for global installations including explosive and hazardous environments.

Latest News Headlines (Sample Titles)

-

Bently Nevada Enhances Relay Logic Capabilities in 3500/32 Modules

-

Global Refinery Adopts 3500/32 Relay Module for Emergency Shutdown Reliability

-

Integration of 3500 Relays with SIS Systems Gains Traction in Process Plants

-

Bently Nevada Updates Relay Module Firmware with Advanced Logic Features

-

Successful Case Study: 3500/32 Used in Critical LNG Plant Safety Application

Frequently Asked Questions (FAQ)

-

What is the function of the 3500/32-01-00 Relay Module?

It outputs machine condition signals through relays, which can trigger alarms or shutdown commands. -

How many relays are included in this module?

The module includes four independent electromechanical relays. -

Can each relay be configured separately?

Yes, each channel can be assigned to specific conditions or logic operations. -

Does it support redundant installation?

Yes, two 3500/32 modules can be configured for redundancy in critical systems. -

What types of alarm conditions can it respond to?

OK, NOT OK, ALERT, DANGER, and custom system events. -

Is the relay operation latched or non-latched?

Both are supported and configurable via software. -

What’s the contact rating of each relay?

Each relay supports up to 5A at 24 VDC or 250 VAC resistive loads. -

Can it operate in hazardous environments?

Yes, with certifications including ATEX, CSA, IECEx, and GOST. -

How is the relay module powered?

Power is supplied directly from the 3500 rack. -

Do I need an additional I/O module for relay connections?

Yes, the 3500/33 Relay I/O Module is used for external wiring access.

Related or Same-Series Models

| Model | Description | Primary Function |

| 3500/33 | 16-Channel Relay Module | High-density alarm/trip relay output |

| 3500/20 | Rack Interface Module | Provides serial communication capabilities |

| 3500/60 | Temperature Monitoring Module | RTD & Thermocouple input monitoring |

| 3500/42M | Proximitor Monitor | Shaft vibration & position measurement |

| 3500/25 | Transient Data Interface (TDI) Module | System controller and System 1® interface |

| 3500/92 | Communication Gateway | Integrates with Modbus systems |

Popular Bently Nevada Models

| Model | Description | Application |

| 3300 XL Proximity Probe | Non-contact shaft position sensor | Vibration and position monitoring |

| 3500/94M | VGA Display Module | Rack-mounted visual system diagnostics |

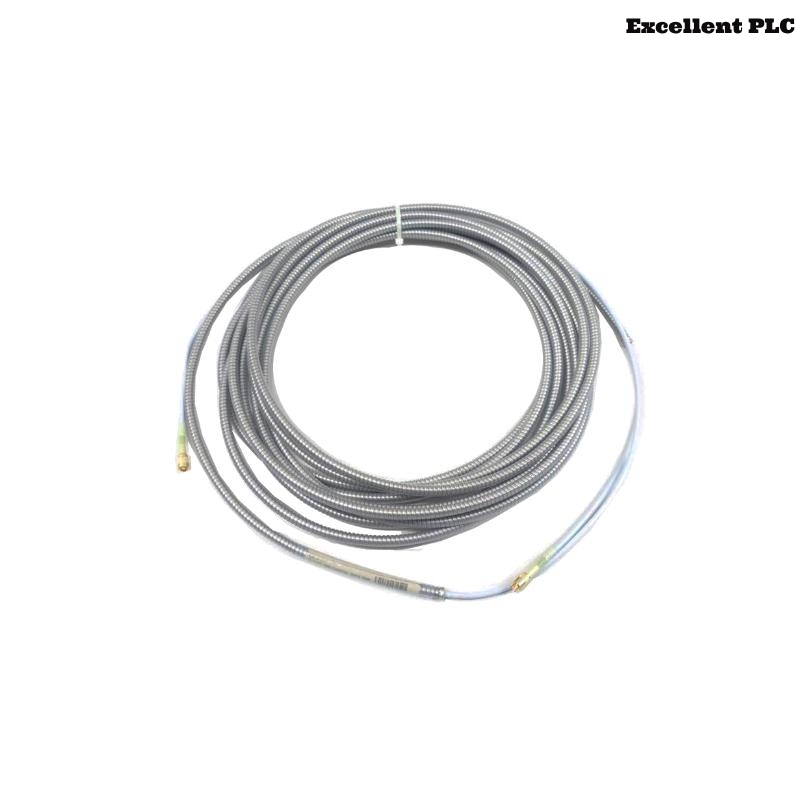

| 330130-040-00-00 | Extension Cable for 3300 Probes | Signal cable from probe to monitor |

| 330180-91-05 | Proximitor Sensor | Probe signal conditioning |

| 3500/15 | Power Supply Module | Provides redundant power to the rack |

| 3500/22M | TDI Power Supply | Supports transient data capture |

Excellent PLC

Excellent PLC