| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

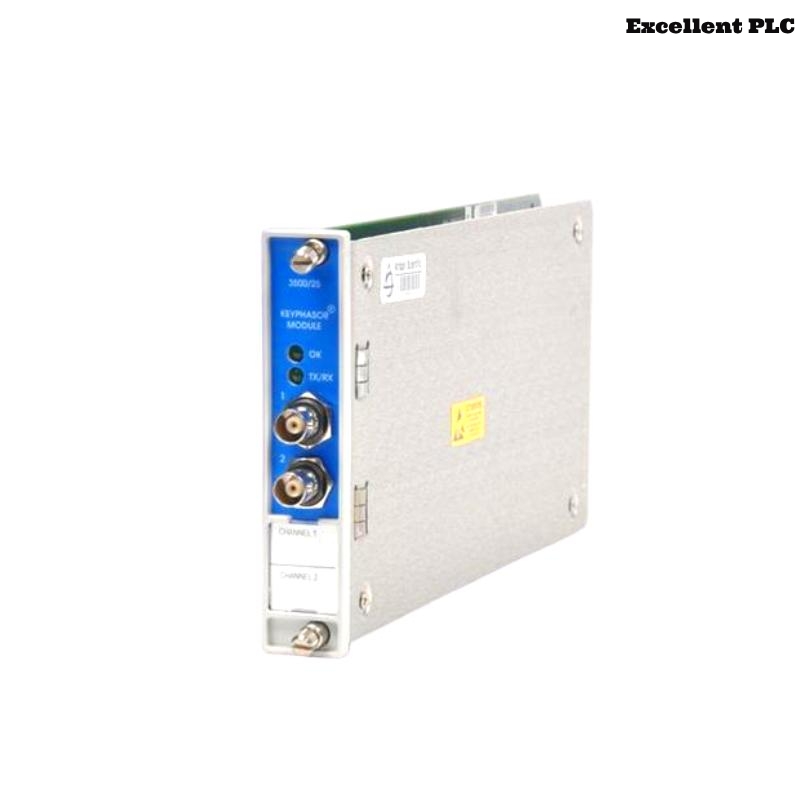

The Bently Nevada 3500/25-01-02-01 Enhanced Keyphasor Module is a critical component within the Bently Nevada 3500 Machinery Protection System. This half-height, two-channel module is designed to provide precise Keyphasor signals to monitor modules within a 3500 rack. By receiving input signals from proximity probes or magnetic pickups, it converts these signals into digital Keyphasor signals that indicate the alignment of the Keyphasor mark on the shaft with the Keyphasor transducer. This functionality is essential for accurate rotational speed measurements and phase reference information, enabling advanced machinery diagnostics and protection.

Technical Specifications

| Parameter | Specification |

| Part Number | 3500/25-01-02-01 |

| Module Type | Enhanced Keyphasor Module |

| Channels | Two (2) independent channels |

| Input Types | Proximity probes or magnetic pickups |

| Input Impedance | Minimum 21.8 kΩ |

| Output Impedance | Maximum 504 Ω |

| Signal Type | Digital Keyphasor signals |

| Mounting | Half-height module for 3500 rack |

| Dimensions (D x W x H) | 241.3 x 24.4 x 103.1 mm |

| Weight | 0.46 kg |

| Agency Approvals | cNRTLus (Class 1, Div 2) |

| Origin | USA |

Applications

The 3500/25-01-02-01 Enhanced Keyphasor Module is utilized in various industrial applications where precise rotational speed and phase reference measurements are critical. Key applications include:

-

Turbomachinery monitoring

-

Rotating equipment diagnostics

-

Condition monitoring systems

-

Predictive maintenance programs

-

Machinery protection systems

-

Industrial automation and control systems

Advantages

The Enhanced Keyphasor Module offers several benefits that enhance machinery monitoring and protection:

-

High Precision: Provides accurate Keyphasor signals for precise rotational speed and phase measurements.

-

Dual-Channel Capability: Supports two independent channels, allowing for redundancy and increased reliability.

-

Compatibility: Fully compatible with existing 3500 systems, facilitating easy integration and upgrades.

-

Compact Design: Half-height module design optimizes space within the 3500 rack.

-

Robust Construction: Designed to operate reliably in harsh industrial environments.

-

Regulatory Compliance: Meets cNRTLus standards for use in hazardous locations (Class 1, Div 2).

Frequently Asked Questions (FAQ)

1. What exactly does the 3500/25-01-02-01 module do in a monitoring system?

The 3500/25-01-02-01 Enhanced Keyphasor Module plays a crucial role in rotating machinery protection by generating a digital Keyphasor signal. This signal serves as a reference mark that corresponds to the position of a rotating shaft. It is used by other modules in the 3500 series rack to determine speed, phase, and the relative position of the rotor. Essentially, it allows the system to correlate vibration data with the shaft’s angular position — a foundation for diagnostics and protection.

2. How is this module connected within the 3500 monitoring rack?

This module is installed in a dedicated slot within the 3500 rack system and works in conjunction with an I/O module. It receives signals from proximity probes or magnetic pickups mounted near the rotating shaft. These inputs are connected to the terminal blocks on the I/O module, and the system processes them into standard Keyphasor signals. Once installed, the module functions as a shared signal source for other modules like the 3500/40M or 3500/42M.

3. What makes the 3500/25-01-02-01 different from a standard Keyphasor module?

This enhanced version of the Keyphasor module supports dual independent channels, allowing two separate Keyphasor inputs. This is particularly useful for applications where multiple shaft reference points are necessary, or redundancy is critical. It also provides improved noise rejection, better diagnostic coverage, and greater compatibility with modern proximity transducers and magnetic pickups compared to earlier generation models.

4. In what kind of industrial systems is this module typically deployed?

The 3500/25-01-02-01 is most commonly used in systems that involve high-speed rotating equipment, such as turbines, compressors, pumps, generators, and expanders. These machines are often found in power plants, petrochemical refineries, natural gas processing facilities, and heavy manufacturing plants. Any machinery with a shaft that requires precise speed and phase monitoring can benefit from the deployment of this module.

5. Can this module be configured for redundant Keyphasor measurements?

Yes, redundancy is one of the core strengths of this module. The two independent channels can either monitor separate shafts or be configured for redundant monitoring of the same shaft. This ensures that if one channel fails, the second channel can still provide the required Keyphasor data, significantly enhancing system reliability and uptime in critical operations.

6. How does this module ensure accurate data in noisy industrial environments?

The module uses advanced signal processing and has a high common-mode rejection ratio to filter out electrical noise, which is common in large industrial environments. Furthermore, its compatibility with high-quality proximity probes ensures a clean signal acquisition. The physical design of the module, along with its EMI shielding and industrial certification (e.g., Class 1, Div 2), adds to its robust performance.

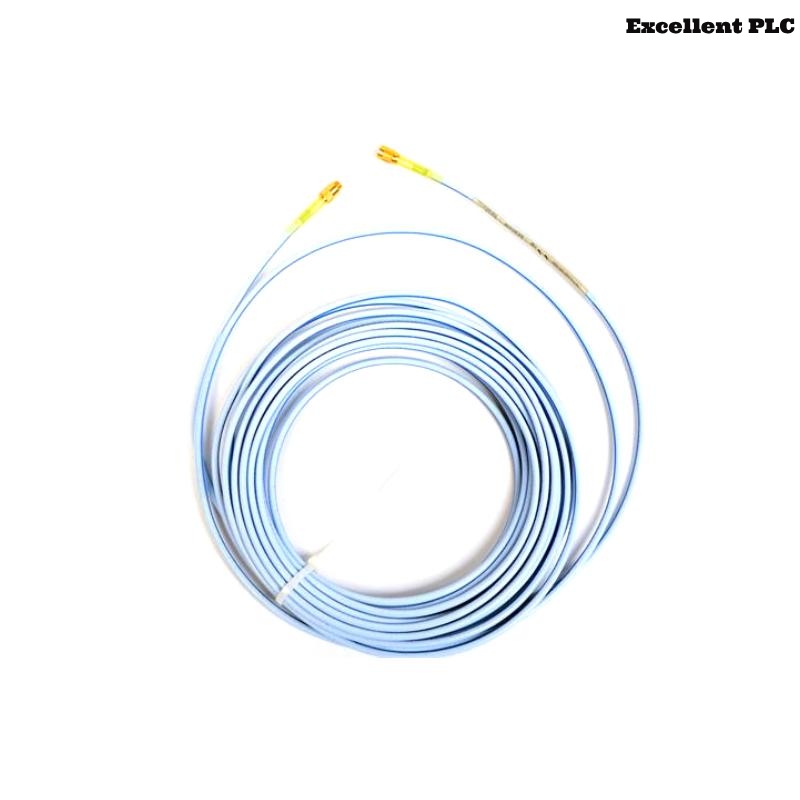

7. What types of probes or pickups can be used with this module?

The module supports both Bently Nevada proximity probes (commonly used for displacement measurements) and magnetic pickups, which detect changes in magnetic fields caused by rotating shaft marks. Compatibility includes the 3300 XL series and other standard Bently Nevada probe systems. The selection of sensor depends on the mechanical configuration and required precision of the machinery being monitored.

8. Does this module support online configuration or diagnostics?

Yes, the module can be configured using the Bently Nevada System 1 software, which allows engineers to set up channel parameters, view waveform data, and monitor performance in real-time. Built-in diagnostic LEDs and system-level integration also help in identifying issues such as channel faults, signal loss, or configuration mismatches quickly.

9. What are the physical dimensions and how much space does it take in the rack?

The module is a half-height unit, designed to fit neatly into the 3500 rack without occupying excess space. Its dimensions are 241.3 x 24.4 x 103.1 mm, making it compact and easy to handle during installation or maintenance. Its compact form allows for multiple modules to be housed in a single rack, supporting more functionality in a smaller footprint.

10. Is the 3500/25-01-02-01 field-replaceable, and what is the typical MTBF?

Yes, it is a field-replaceable module. Bently Nevada designs its monitoring systems with hot-swappable components, so replacing this module can often be done without shutting down the entire system, depending on the configuration. The Mean Time Between Failures (MTBF) for Bently Nevada components like this one is typically in the range of 100,000+ hours, indicating high reliability for long-term industrial operation.

Related Models (Same Series or Functional Type)

| Model | Description |

| 3500/25-01-01-00 | Enhanced Keyphasor Module with basic configuration |

| 3500/25-02-01-00 | Keyphasor I/O Module for 3500/25 series |

| 3500/22M | Transient Data Interface Module (System communication module) |

| 3500/60 | Temperature Monitoring Module |

| 3500/42M | Proximitor/Seismic Monitor Module |

| 3500/05 | System Rack for mounting 3500 modules |

Popular Models from Bently Nevada

| Model | Description |

| 3300 XL 8mm Proximity | Industry-standard proximity probe for vibration measurement |

| 3500/40M | Proximitor Monitor for shaft vibration and position |

| 3500/93 | Display Interface Module (color screen for data display) |

| 3500/15 | Power Supply Module for the 3500 system |

| 3500/32M | 4-Channel Relay Module for machinery shutdown logic |

| 3500/20 | Rack Interface Module for external system communication |

Excellent PLC

Excellent PLC