| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

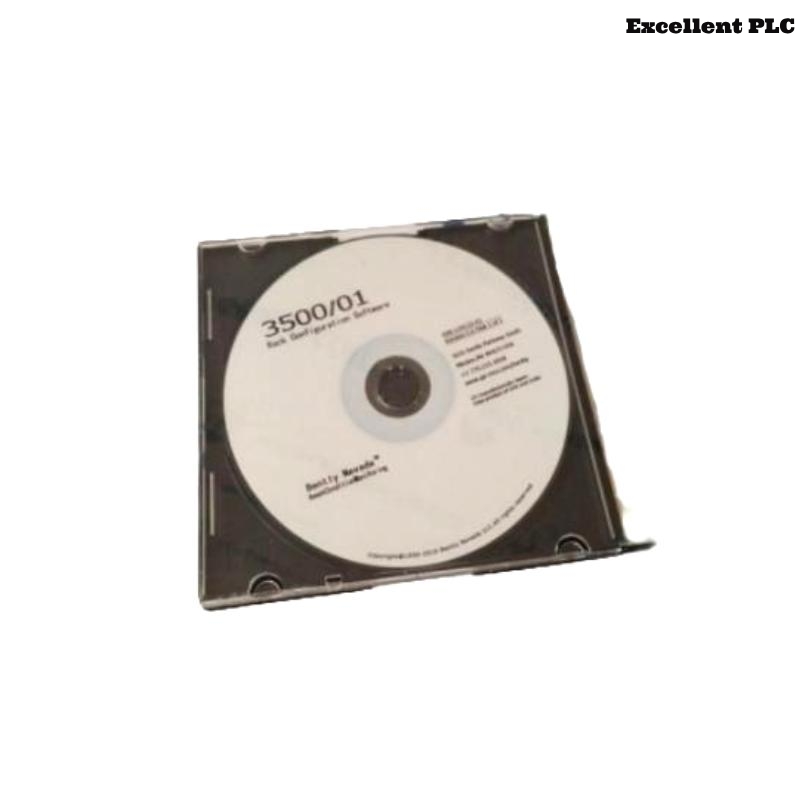

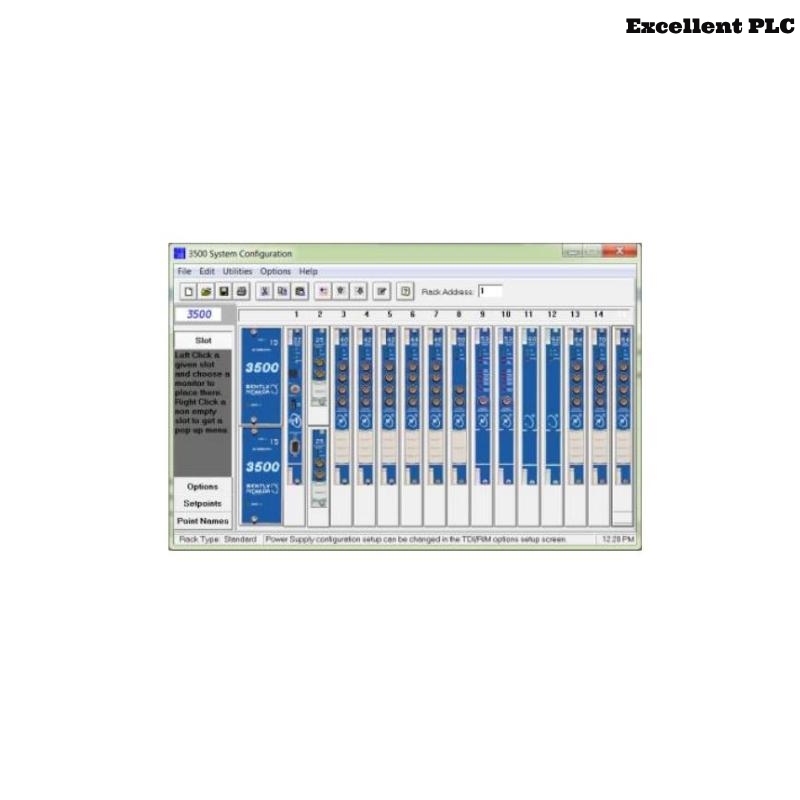

The Bently Nevada 3500/01-01 Rack Configuration Software is an essential software utility designed specifically for configuring and managing the Bently Nevada 3500 Series Machinery Protection System. This utility allows system integrators, field engineers, and maintenance teams to configure every module within the 3500 rack — including vibration monitors, relay modules, communication interfaces, and system parameters.

The software supports intuitive drag-and-drop configuration, module diagnostics, and advanced customization to adapt to unique plant or machine requirements. With real-time communication to the rack via a serial or Ethernet interface, users can upload, download, and verify configuration files, track changes, and maintain version control across the system.

Built with Bently Nevada’s legacy of high-reliability condition monitoring, the 3500/01-01 software is vital for industries that depend on accurate, fast, and secure monitoring of critical rotating machinery.

Product Specifications

| Parameter | Description |

| Product Name | Bently Nevada 3500/01-01 |

| Type | Rack Configuration Software |

| Compatible System | Bently Nevada 3500 Series |

| Communication Protocols | RS232, RS485, Ethernet |

| Supported Operating Systems | Windows 7, 10, 11 (64-bit recommended) |

| License Type | Perpetual or Floating (based on system configuration) |

| Functionality | Rack configuration, firmware update, module diagnostics, data logging |

| Display Support | 1024×768 resolution or higher |

| Processor Requirement | 1.8 GHz Dual Core or higher |

| Memory Requirement | Minimum 4 GB RAM |

| Disk Space Requirement | 500 MB free space |

| Network Connectivity | Required for remote configuration |

| Language Support | English, Chinese, Spanish, German, French |

| Software Size (Installer) | Approx. 280 MB |

| Shipping Weight | 2 kg |

Applications

-

System Setup for 3500 Series Racks: Enables full configuration of vibration monitors, relay logic, tachometer inputs, and display modules.

-

Machinery Protection: Used in industries where machinery condition monitoring is critical, including:

-

Oil & Gas

-

Power Generation

-

Petrochemical Plants

-

Pulp & Paper

-

Water Treatment Facilities

-

-

Remote Configuration: Supports remote commissioning and diagnostics via network access.

-

Maintenance & Troubleshooting: Ideal for maintenance teams conducting diagnostics or firmware updates.

-

System Integration: Frequently used by system integrators for turnkey project deployment.

Advantages

-

Full Control Over Rack Setup: Users can configure, edit, and update the entire rack from one interface.

-

Time-Saving Configuration: Pre-configured templates and auto-detect functions reduce engineering time.

-

Error Detection: Built-in logic checks catch configuration mismatches or missing modules.

-

Secure Configuration Handling: Offers versioning, backups, and password protections.

-

Remote Management Capability: Allows for rack setup without requiring on-site presence.

-

Multi-language Interface: Ideal for international engineering teams.

-

Seamless Firmware Updates: Keeps your rack and modules running on the latest firmware.

-

Diagnostic Access: View live module health, error logs, and signal trends.

Latest News Headlines (Industry/Brand Related)

-

“Bently Nevada Expands Digital Toolset for Industrial Condition Monitoring”

-

“GE’s Bently Nevada 3500 System Still the Industry Standard for Vibration Protection”

-

“New Configuration Tools Improve Plant Reliability, Cut Downtime”

-

“Bently Nevada Software Enables Remote Monitoring Across Global Sites”

-

“Enhancements to 3500/01 Software Add Cybersecurity and Template Tools”

Frequently Asked Questions (FAQ)

-

Q: Is the 3500/01-01 software backward compatible with older 3500 modules?

A: Yes, the software supports both legacy and newer 3500 modules, including firmware updates. -

Q: Can the software be used for remote diagnostics?

A: Yes, via Ethernet or serial communication with proper security settings enabled. -

Q: Is training required to use the software effectively?

A: While it’s user-friendly, formal training is recommended for advanced configuration tasks. -

Q: What is the licensing model of this software?

A: Both perpetual and floating licenses are available, depending on site and project needs. -

Q: How often is the software updated?

A: Bently Nevada releases updates periodically with bug fixes and new feature enhancements. -

Q: Can I configure a rack offline and then upload it later?

A: Absolutely. You can build and save the configuration file, then load it when connected. -

Q: What happens if the rack configuration fails?

A: The software provides diagnostic messages and roll-back options for troubleshooting. -

Q: Does the software support configuration backups?

A: Yes, you can export configuration backups in secure file formats. -

Q: Is this software compatible with Windows 11?

A: Yes, it is tested and compatible with Windows 11 (64-bit). -

Q: Is internet access required to use the software?

A: Not for rack configuration. However, internet may be needed for license validation or updates.

Related Models (Same Series or Function)

| Model Number | Description | Function |

| 3500/01-02 | Rack Configuration Software with Advanced Diagnostics | Includes expanded diagnostic logging |

| 3500/15 | Power Supply Module | Provides power to the rack system |

| 3500/20 | Rack Interface Module | Communication interface between rack & host |

| 3500/22M | Transient Data Interface | For high-speed data capture and diagnostics |

| 3500/94 | Display Interface Module | Local display interface for rack data |

| 3500/60 | Temperature Monitor Module | Monitors bearing and process temperatures |

Popular Models from Bently Nevada (Same Brand)

| Model Number | Description | Key Application |

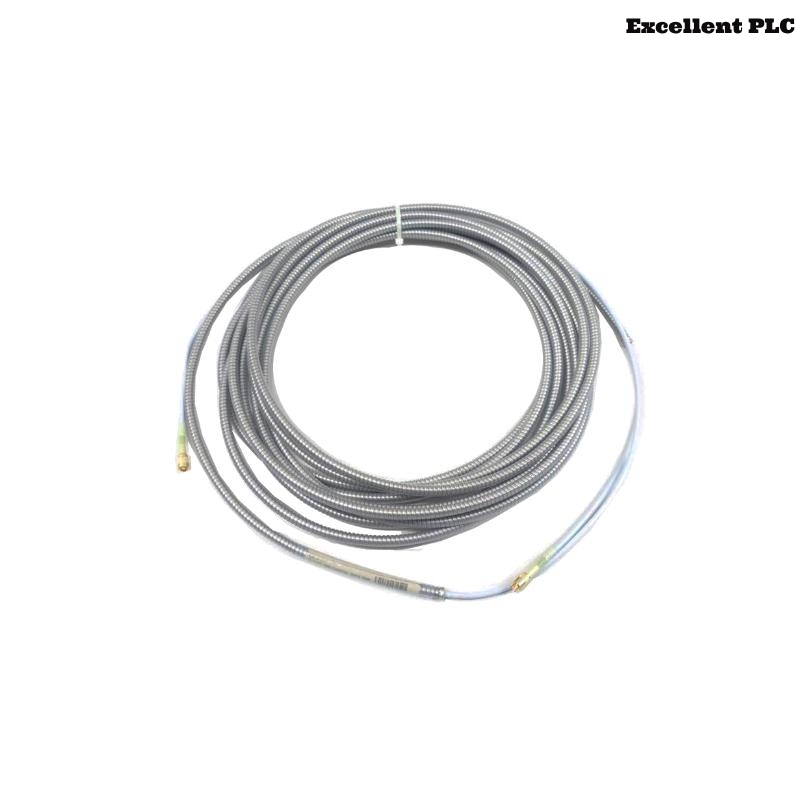

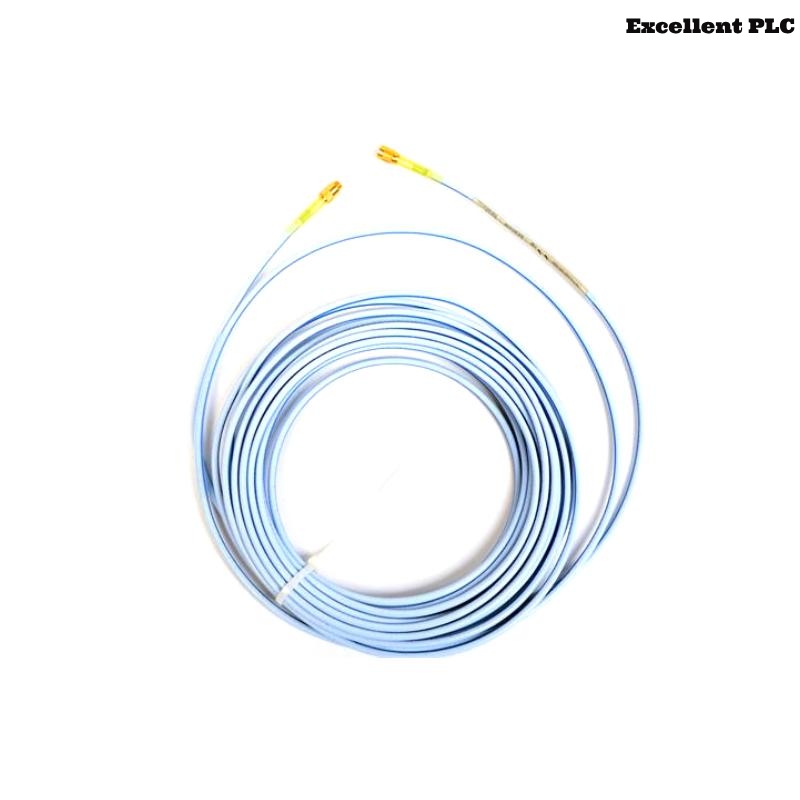

| 330104-00-05 | Reverse Mount Probe | Space-constrained machinery monitoring |

| 3500/42M | Proximitor/Seismic Monitor | Monitors shaft vibration and casing motion |

| 3500/33 | Relay Module | Activates alarms based on system parameters |

| 3500/94M | Touchscreen Display Module | User interface for system data |

| 3500/93 | System Display Interface | Outputs rack data to remote locations |

| 3300 XL Series | Complete Proximity Sensor Family | Vibration and axial position monitoring |

Excellent PLC

Excellent PLC