| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

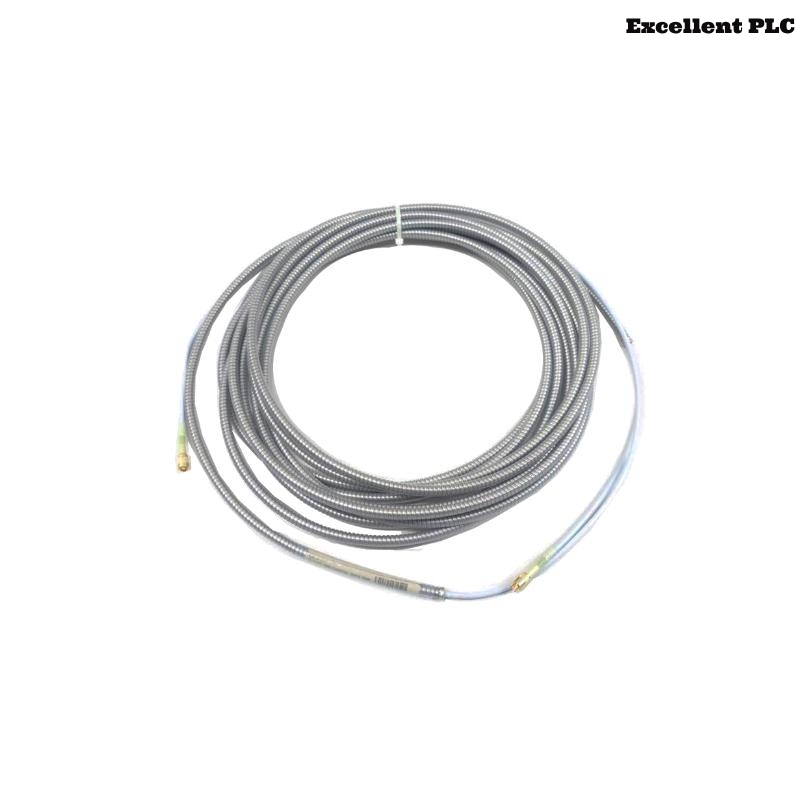

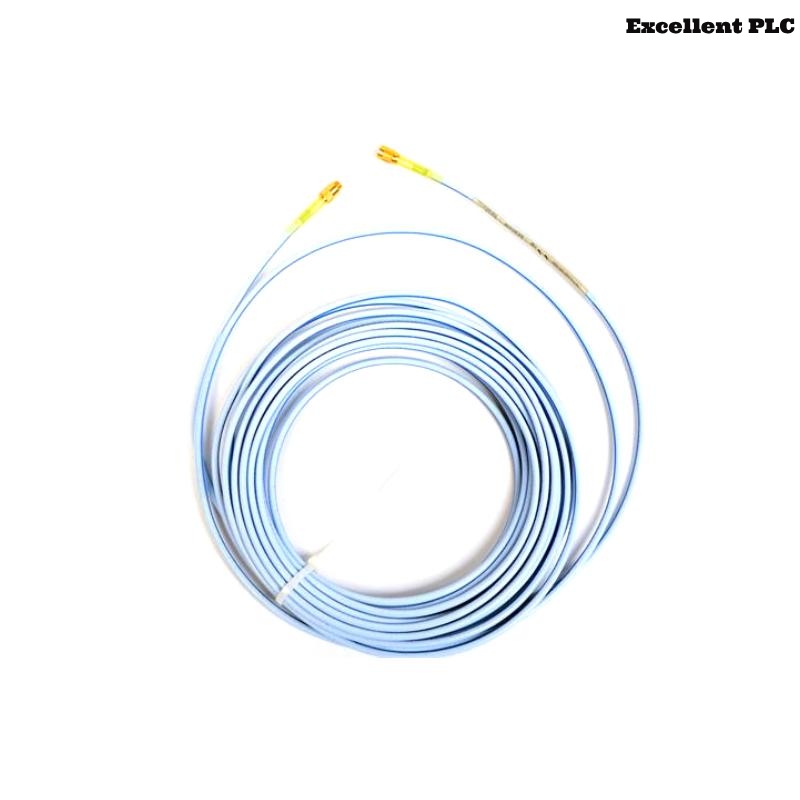

The Bently Nevada 330100-90-00 3300 Proximitor Sensor is a critical component in vibration monitoring systems designed by Bently Nevada, a globally recognized leader in condition monitoring and protection systems for rotating machinery. This sensor belongs to the 3300 series and is used in proximity sensing systems to detect and monitor shaft position and vibration in industrial rotating equipment such as turbines, compressors, pumps, and motors.

The 330100-90-00 sensor works in conjunction with matching probes and extension cables to provide precise, reliable measurements in high-temperature, high-vibration environments. Known for its stability, linearity, and robust design, it ensures long-term performance and consistent data output, making it a preferred choice in critical machinery monitoring applications.

Product Specifications

| Parameter | Description |

|---|---|

| Model | 330100-90-00 |

| Series | 3300 Proximitor Series |

| Measurement Range | 0 to 2 mm (80 mils) |

| Linear Range | 0.25 mm to 2.0 mm (10 mils to 80 mils) |

| Sensitivity | 7.87 mV/μm (200 mV/mil) ±5% |

| Frequency Response | 0 to 10 kHz |

| Operating Temperature | -35°C to +100°C (-31°F to +212°F) |

| Storage Temperature | -51°C to +177°C (-60°F to +350°F) |

| Relative Humidity | 0 to 95%, non-condensing |

| Power Supply | -24 Vdc (nominal), supplied by 3300 monitoring system |

| Output | Voltage output proportional to gap distance |

| Material | Epoxy-coated, rugged industrial enclosure |

| Mounting | DIN rail or panel mounting |

| Total Length | 9 metres |

| Weight | 0.29 kg |

| Connector Type | 3-pin connector for extension cable |

| Compliance | CE, RoHS |

Applications

The 330100-90-00 3300 Proximitor Sensor is commonly deployed in:

-

Steam and Gas Turbines – to monitor shaft vibration and position.

-

Centrifugal Compressors – for real-time bearing and shaft condition monitoring.

-

Electric Motors and Generators – for detecting misalignment or imbalance.

-

Pumps – for cavitation and wear monitoring.

-

Gearboxes – for gear mesh condition analysis.

-

Industrial Fans and Blowers – for balance and resonance detection.

The sensor is designed for critical applications where failure could result in unplanned shutdowns or safety risks.

Product Advantages

-

High Accuracy & Sensitivity: Provides precise and repeatable proximity measurements, essential for early fault detection.

-

Wide Operating Range: Performs reliably in extreme temperatures and harsh industrial conditions.

-

Modular Design: Easily integrated with 3300 series probes and monitoring systems.

-

Low Noise Output: Ensures signal stability and accuracy over extended distances.

-

Proven Reliability: Widely used in safety-critical environments worldwide.

-

Compact & Rugged Housing: Allows for installation in confined or vibration-intensive areas.

Frequently Asked Questions (FAQs)

-

What is the primary function of the Bently Nevada 330100-90-00 sensor?

It measures the distance (gap) between the probe tip and the shaft surface, allowing monitoring of shaft position and vibration. -

What probes are compatible with this Proximitor Sensor?

The 330100-90-00 is typically used with 3300 XL series proximity probes and extension cables. -

Can the sensor be mounted near high-temperature machinery?

Yes, the sensor operates effectively up to 100°C and can be used with high-temperature-rated probes for turbine applications. -

Does the sensor output an analog or digital signal?

The sensor outputs an analog voltage signal proportional to the distance between the probe and the target. -

Is it suitable for hazardous or classified areas?

It can be used in hazardous areas when installed in compliance with local and international standards using certified equipment. -

What kind of maintenance does this sensor require?

Very minimal. Periodic visual inspection and connector integrity checks are typically sufficient. -

Can this sensor detect shaft rub or eccentricity?

Yes, it is specifically designed to detect radial shaft vibration and axial position changes, including rubs and misalignment. -

Is there a calibration process required during installation?

Calibration is typically done by verifying system sensitivity using a micrometer and adjusting gap voltage during commissioning. -

How is the sensor connected to the monitoring system?

Through a three-pin connector and extension cable that links the probe, extension cable, and proximitor sensor to the monitor. -

What monitoring systems are compatible with this sensor?

It is compatible with Bently Nevada 3300, 3500, and some customized monitoring configurations using analog input modules.

Related Models from the Same Series

| Model | Description | Measurement Range | Connector Type |

|---|---|---|---|

| 330100-50-00 | 3300 Proximitor Sensor, 5m System Length | 0–2 mm | 3-pin |

| 330100-70-00 | 3300 Proximitor Sensor, 7m System Length | 0–2 mm | 3-pin |

| 330100-XX-08-XX | 3300 Proximitor Sensor, Multiple Configurable | 0–2 mm | Multiple options |

| 330130-040-00-00 | 3300 XL 8 mm Proximity Probe | N/A | Micro-dot |

| 330180-51-00 | 3300 XL Extension Cable, 5m | N/A | Micro-dot to 3-pin |

| 330101-00-20-10-02-00 | Proximitor Assembly for harsh environments | 0–2 mm | Epoxy-sealed |

Popular Models from Bently Nevada (Same Brand)

| Model | Description | Application | Type |

|---|---|---|---|

| 3500/22M | Transient Data Interface Module | Data Collection | Monitoring Module |

| 3500/42M | Proximitor/Seismic Monitor | Vibration Monitoring | Monitor |

| 3500/15 | Power Supply Module | System Power | Power Module |

| 3500/05 | System Rack | Chassis Housing | Mounting Frame |

| 330730-040-00-00 | NSv 5mm Proximity Probe | Small Shaft Monitoring | Proximity Probe |

| 3701/44 TDI | Dynamic Protection & Condition Monitoring Module | Turbine Monitoring | Monitoring Unit |

Excellent PLC

Excellent PLC