| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction:

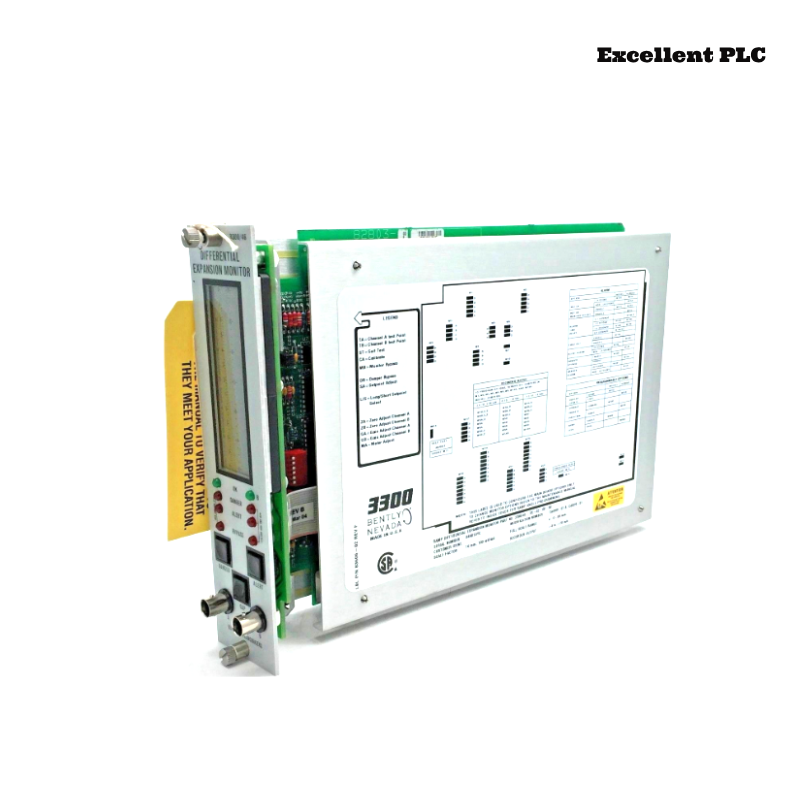

The Bently Nevada 3300/46-08-03-01-00 Differential Expansion Monitor is a state-of-the-art monitoring device used in machinery protection and monitoring applications. It is designed specifically to measure the differential expansion between two points of a rotating shaft, such as in turbines, compressors, or other critical rotating machinery. The differential expansion is vital in understanding the thermal growth and mechanical alignment of the machinery, ensuring it operates within safe parameters.

This monitor is part of the Bently Nevada 3300 series, known for its high precision and reliability in industrial environments. The system is engineered to help identify potential issues before they cause significant damage, thus reducing downtime and maintenance costs.

Product Specifications:

Here’s a detailed overview of the specifications for the 3300/46-08-03-01-00 model:

| Specification | Value |

|---|---|

| Model Number | 3300/46-08-03-01-00 |

| Measurement Type | Differential Expansion |

| Input Range | 0 to 25 mm |

| Output Type | Analog Output (4-20 mA) |

| Operating Voltage | 18-30 VDC |

| Mounting Type | DIN Rail Mount |

| Response Time | < 10 ms |

| Operating Temperature Range | -40°C to +85°C |

| Vertical Dimension | 83 mm |

| Weight | 1 kg |

| Signal Type | Differential Signal |

| Certification | CE, UL, CSA |

Applications:

The 3300/46-08-03-01-00 Differential Expansion Monitor is widely used in industries where precise measurements of the expansion between parts of rotating machinery are crucial. Some key applications include:

-

Turbine Monitoring: Used in steam and gas turbines for differential expansion measurement, ensuring thermal growth is accounted for and that the machinery remains aligned.

-

Compressor Protection: Helps in monitoring differential expansion in compressors, which can indicate potential mechanical failure.

-

Generators: Used for monitoring generator alignment and thermal growth.

-

Industrial Pumps: Ensures the expansion in pump shafts is within acceptable limits to avoid mechanical issues.

-

Oil & Gas Plants: Critical in offshore and onshore facilities where machinery uptime is vital to operations.

Product Advantages:

-

Precision Measurement: Offers high-precision differential expansion measurements, essential for detecting misalignments and thermal distortions.

-

Early Fault Detection: Provides early warnings about mechanical or thermal issues, reducing the risk of catastrophic failure.

-

Cost-Effective: Minimizes downtime and repair costs by enabling predictive maintenance.

-

Rugged Design: Built to withstand harsh industrial environments, including extreme temperatures and vibrations.

-

Simple Integration: Easy to integrate with existing machinery protection systems, thanks to its compatibility with common industrial protocols and its modular design.

-

Reliable Signal Processing: Provides stable and accurate analog outputs for further monitoring or control systems.

-

Enhanced Safety: By providing real-time feedback on machinery condition, it enhances the overall safety of plant operations.

-

Long Lifespan: Designed for longevity, ensuring the product remains operational even in demanding conditions over long periods.

Latest News Titles:

-

Bently Nevada Launches New Differential Expansion Monitor Model for Enhanced Machinery Protection

-

Bently Nevada’s 3300/46-08-03-01-00 Monitor: A Key Component in Reducing Turbine Downtime

-

Ensuring Safe Operations with the Bently Nevada Differential Expansion Monitor

-

How the Bently Nevada 3300/46-08-03-01-00 is Revolutionizing Equipment Monitoring in Power Plants

-

Differential Expansion Monitoring: A New Era in Turbine Protection Technology

-

Reducing Preventative Maintenance Costs with the Bently Nevada Differential Expansion System

-

Bently Nevada 3300 Series: Setting New Standards in Rotating Equipment Monitoring

-

Bently Nevada Enhances Real-Time Performance with Differential Expansion Monitoring Technology

-

Key Benefits of Using the Bently Nevada 3300/46-08-03-01-00 in Industrial Applications

-

Bently Nevada Announces New Enhancements to its Differential Expansion Monitoring Technology

Frequently Asked Questions (FAQ):

-

What is the purpose of the Bently Nevada 3300/46-08-03-01-00 monitor?

-

The monitor is used to measure the differential expansion between two points of a rotating shaft, such as in turbines, compressors, and other rotating machinery.

-

-

How does the differential expansion measurement help in machinery protection?

-

It helps detect misalignments, thermal growth, or mechanical failures that could lead to machinery damage, allowing for early intervention.

-

-

What is the input range of this monitor?

-

The input range is from 0 to 25 mm, providing precise measurements for the machinery’s thermal expansion.

-

-

Can the Bently Nevada 3300/46-08-03-01-00 be integrated into existing monitoring systems?

-

Yes, it is designed for easy integration with common industrial monitoring systems, using analog outputs and standard communication protocols.

-

-

What kind of output does this monitor provide?

-

The monitor provides an analog 4-20 mA output, which can be used for further monitoring or control.

-

-

What are the environmental operating conditions for the monitor?

-

The monitor operates in temperatures ranging from -40°C to +85°C, making it suitable for harsh industrial environments.

-

-

Is the monitor certified for use in hazardous environments?

-

Yes, the monitor has CE, UL, and CSA certifications, ensuring compliance with international standards for safety and reliability.

-

-

How easy is it to install the 3300/46-08-03-01-00?

-

The monitor is designed for easy installation on DIN rails, making it quick to integrate into existing systems.

-

-

What is the response time of the Bently Nevada 3300/46-08-03-01-00?

-

The monitor has a fast response time of less than 10 milliseconds, ensuring real-time performance monitoring.

-

-

What are the dimensions and weight of the monitor?

-

The vertical dimension 83 mm and weighs 1 kg.

Recommended Related Models:

| Model Number | Description | Key Features |

|---|---|---|

| 3300/46-08-03-01-01 | Differential Expansion Monitor | Similar to 3300/46-08-03-01-00, with minor configuration changes |

| 3300/47-08-03-01-00 | Shaft Expansion Monitor | Suitable for larger machinery, higher input range |

| 3300/46-10-03-01-00 | Differential Expansion Monitor with advanced diagnostics | Offers additional diagnostic capabilities |

| 3300/46-08-04-01-00 | Differential Expansion Monitor | With added temperature sensors for more accurate measurements |

| 3300/46-09-03-01-00 | Dual Shaft Expansion Monitor | Monitors two shafts simultaneously for complex systems |

| 3300/46-07-03-01-00 | Basic Differential Expansion Monitor | Cost-effective version with standard output features |

| 3300/46-08-03-01-02 | Differential Expansion Monitor with enhanced signal processing | Improved signal processing for more accurate readings |

| 3300/46-08-05-01-00 | Differential Expansion Monitor with remote access | Remote diagnostic and monitoring capabilities |

Popular Models from Bently Nevada:

| Model Number | Description | Key Features |

|---|---|---|

| 3300/20-01-01-00 | Proximity Transducer | Measures shaft displacement with high precision |

| 3300/04-01-01-00 | Vibration Transducer | Provides continuous vibration monitoring |

| 3500/42M | Dynamic Pressure Monitor | Used for high-end pressure monitoring in critical systems |

| 3300/22-01-01-00 | Radial Vibration Monitor | Offers advanced radial vibration monitoring |

| 3500/40 | High-Speed Data Acquisition Module | Enables real-time data acquisition for multiple sensors |

| 3300/04-02-01-00 | Vibration Transducer with extended range | Designed for heavy machinery applications |

| 3500/30 | Machinery Protection System | Full machinery protection system with various sensor inputs |

| 3500/15 | Bearing Protection System | Provides bearing condition monitoring and protection |

Excellent PLC

Excellent PLC