| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

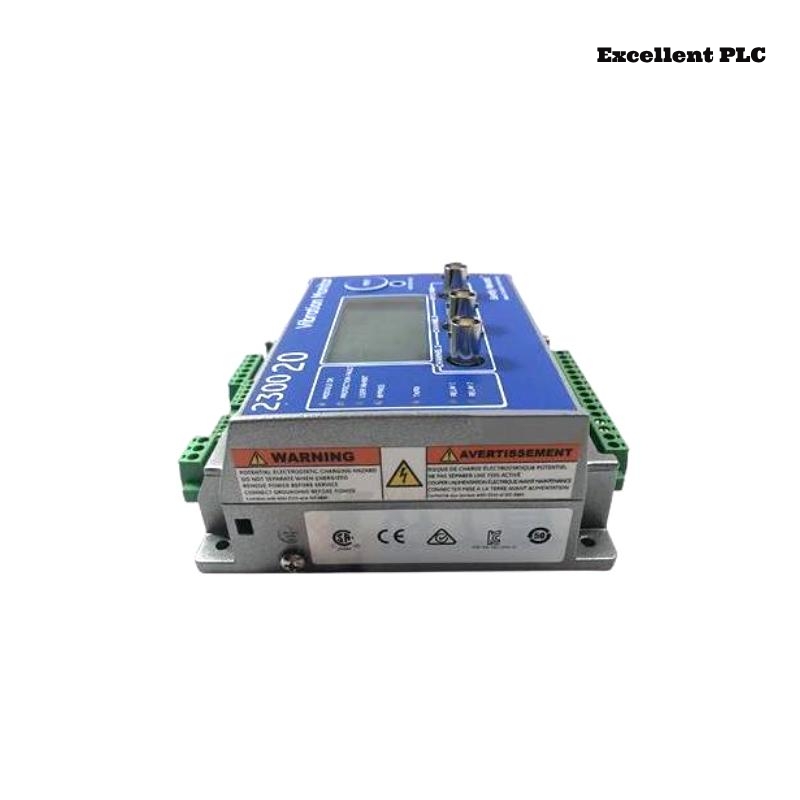

The Bently Nevada 2300/20-00 Vibration Monitor is a highly reliable and efficient monitoring system designed for rotating machinery such as pumps, motors, compressors, and turbines. This model is part of the 2300 series, which provides continuous condition monitoring and early fault detection to prevent catastrophic failures and unplanned downtime.

The 2300/20-00 features dual-channel vibration monitoring, real-time data processing, and multiple communication interfaces, making it a powerful solution for both standalone and integrated system applications. Designed to meet the rigorous demands of industrial environments, this monitor offers high sensitivity and precision, ensuring that operators can detect potential mechanical faults before they lead to serious equipment damage.

With compliance to industry standards and seamless integration capabilities with Bently Nevada’s System 1 software, the 2300/20-00 Vibration Monitor is an essential tool for predictive maintenance and asset protection.

Product Specifications

The technical specifications of the Bently Nevada 2300/20-00 Vibration Monitor are as follows:

| Parameter | Specification |

|---|---|

| Product Type | Vibration Monitor |

| Model Number | 2300/20-00 |

| Number of Channels | 2 Vibration Channels + 1 Speed Channel |

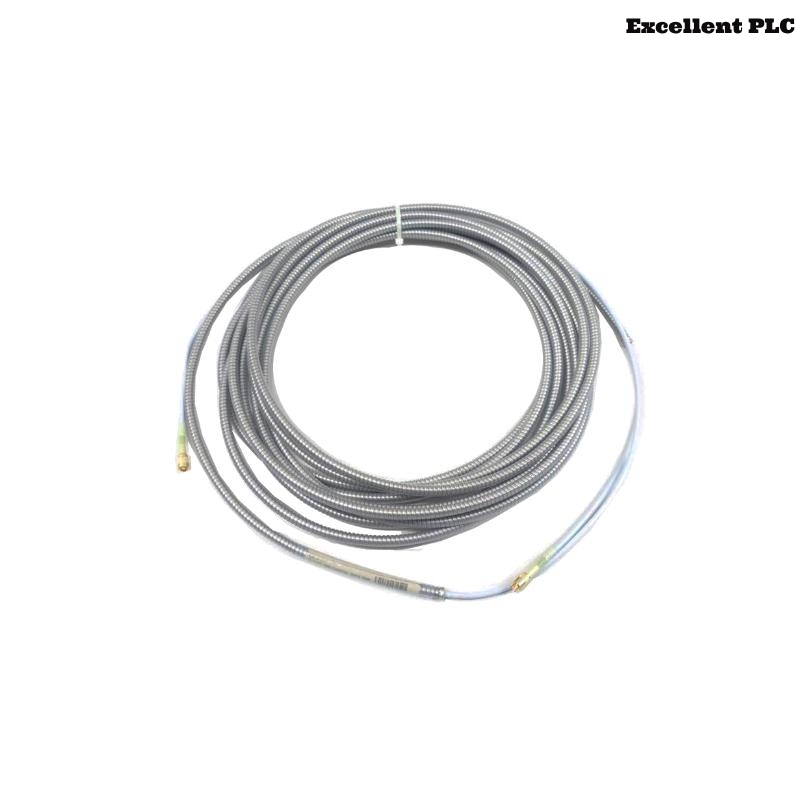

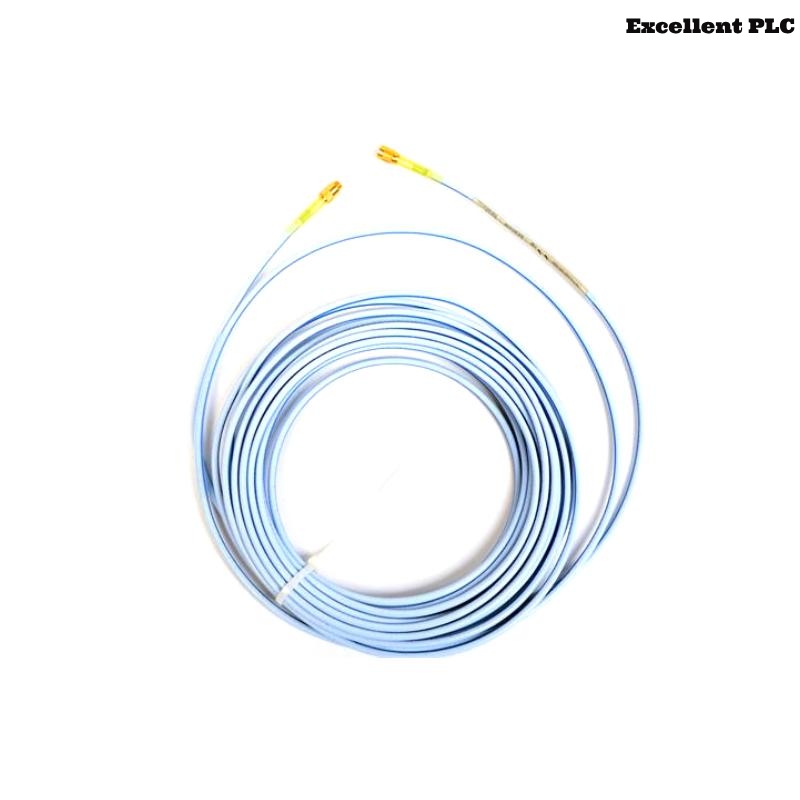

| Input Type | Accelerometers, Velometers, Proximity Probes |

| Frequency Range | 0.5 Hz – 10 kHz |

| Dynamic Range | 90 dB (typical) |

| Communication Protocol | Modbus RTU, RS-485 |

| Alarm Types | Alert, Danger, System Fault |

| Display | LED Status Indicators |

| Operating Voltage | 24V DC (±10%) |

| Power Consumption | < 5W |

| Dimensions (L x W x H) | 127 x 127 x 76.2 mm |

| Weight | 1.03 kg |

| Mounting Type | DIN Rail Mount or Panel Mount |

| Operating Temperature | -20°C to 65°C |

| Humidity | 0-95% RH, non-condensing |

| Protection Class | IP20 (Indoor Use) |

| Compliance Standards | ISO 10816, API 670, CE, RoHS |

Product Applications

The Bently Nevada 2300/20-00 Vibration Monitor is widely used across various industries for condition monitoring and predictive maintenance. Some key applications include:

-

Pumps & Motors: Detects imbalance, misalignment, and bearing wear.

-

Compressors: Monitors vibration levels to prevent mechanical failures.

-

Turbines: Provides real-time condition monitoring to avoid downtime.

-

Centrifuges: Ensures smooth operation by identifying early-stage faults.

-

Blowers & Fans: Helps in diagnosing imbalance and blade defects.

-

Industrial Gearboxes: Monitors gear mesh frequencies for early fault detection.

-

Paper Mills & Steel Plants: Ensures the longevity of rotating machinery.

-

Oil & Gas Refineries: Provides critical protection for expensive rotating assets.

Product Advantages

-

Dual-Channel Monitoring: Supports two vibration channels and one speed channel for comprehensive monitoring.

-

Wide Frequency Range: Covers 0.5 Hz to 10 kHz, ensuring accurate detection of a broad range of faults.

-

Advanced Communication Protocols: Equipped with Modbus RTU and RS-485 for seamless integration into industrial control systems.

-

Real-Time Alerts & Alarms: Provides Alert, Danger, and System Fault alarms to notify operators of abnormal conditions.

-

High Dynamic Range: With a 90 dB dynamic range, it ensures accurate signal processing and fault detection.

-

Compact & Easy Installation: The DIN rail and panel mount compatibility make installation simple and versatile.

-

Low Power Consumption: Consumes less than 5W, making it an energy-efficient choice for continuous monitoring.

-

Industry Compliance: Designed to meet ISO 10816, API 670, CE, and RoHS standards, ensuring high reliability.

Latest News Headlines

-

“Bently Nevada Enhances Predictive Maintenance with the 2300/20-00 Monitor”

-

“New Vibration Monitoring Solutions for Rotating Equipment Launched by Bently Nevada”

-

“Prevent Equipment Failures with the Advanced 2300/20-00 System”

-

“Bently Nevada Introduces Smart Diagnostics with the 2300 Series”

-

“Industry 4.0: How 2300/20-00 Supports Digital Transformation in Manufacturing”

-

“Reduce Downtime and Improve Safety with Bently Nevada’s Newest Vibration Monitor”

-

“Bently Nevada Expands Condition Monitoring Solutions with the 2300 Series”

-

“Leveraging AI and Predictive Analytics with the 2300/20-00 Vibration Monitor”

Frequently Asked Questions (FAQ)

-

What is the primary purpose of the Bently Nevada 2300/20-00?

-

It is used for continuous condition monitoring and early fault detection in rotating machinery.

-

-

What types of sensors does it support?

-

It supports accelerometers, velometers, and proximity probes.

-

-

How many channels does it have?

-

It has two vibration channels and one speed channel.

-

-

What is the frequency range?

-

It operates within 0.5 Hz to 10 kHz.

-

-

What communication interfaces are available?

-

It supports Modbus RTU and RS-485 for industrial communication.

-

-

Can it be mounted on a DIN rail?

-

Yes, it supports both DIN rail and panel mounting.

-

-

Does it provide real-time alarms?

-

Yes, it offers Alert, Danger, and System Fault alarms.

-

-

Is the 2300/20-00 compliant with industrial standards?

-

Yes, it meets ISO 10816, API 670, CE, and RoHS standards.

-

-

What is the power consumption?

-

It consumes less than 5W.

-

-

What industries commonly use this monitor?

-

It is widely used in oil & gas, power generation, manufacturing, and heavy industry.

Related Models in the Same Series

| Model Number | Description |

|---|---|

| 2300/10-00 | Single-channel vibration monitor |

| 2300/15-00 | Advanced vibration monitor with additional features |

| 2300/20-01 | Enhanced model with improved diagnostic capabilities |

| 2300/25-00 | Multi-channel vibration monitoring system |

| 2300/30-00 | Vibration monitor with extended environmental range |

| 2300/35-00 | High-sensitivity model for critical applications |

| 2300/40-00 | Wireless-enabled vibration monitor |

| 2300/45-00 | Integrated condition monitoring and diagnostics |

Popular Bently Nevada Models

| Model Number | Description |

|---|---|

| 3300/12-00 | High-speed proximity monitoring system |

| 3300/20-00 | Advanced vibration monitoring module |

| 3500/22M | System 1 compatible condition monitoring device |

| 3500/32 | Advanced dynamic pressure monitoring system |

| 3701/40 | Wireless vibration monitoring system |

| 990 Vibration Transmitter | Compact transmitter for basic vibration monitoring |

| ADRE 408 | Portable diagnostic data acquisition system |

| SCOUT200 | Wireless vibration analyzer |

Excellent PLC

Excellent PLC