| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview:

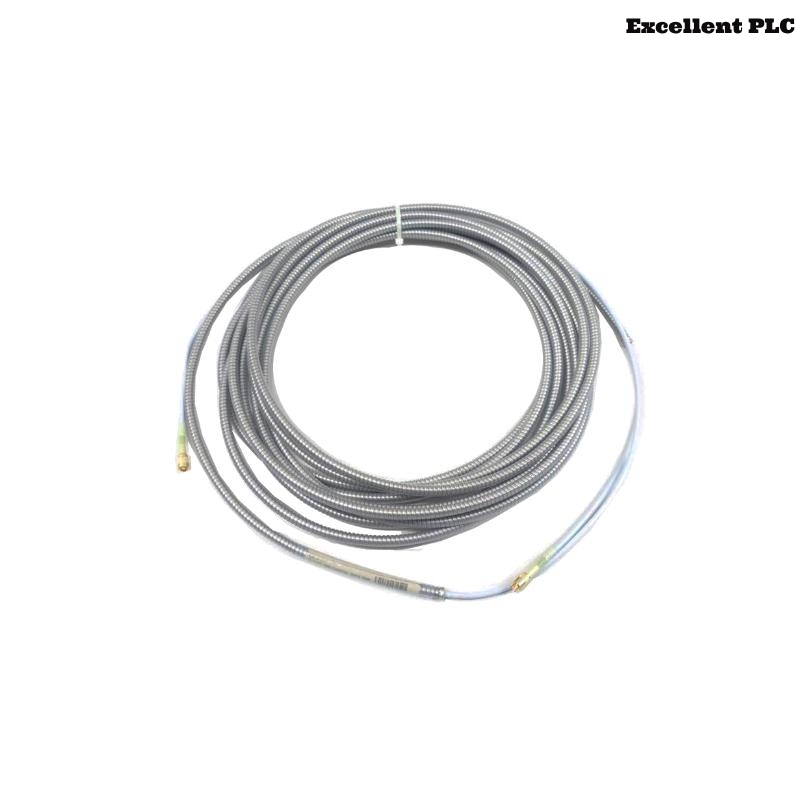

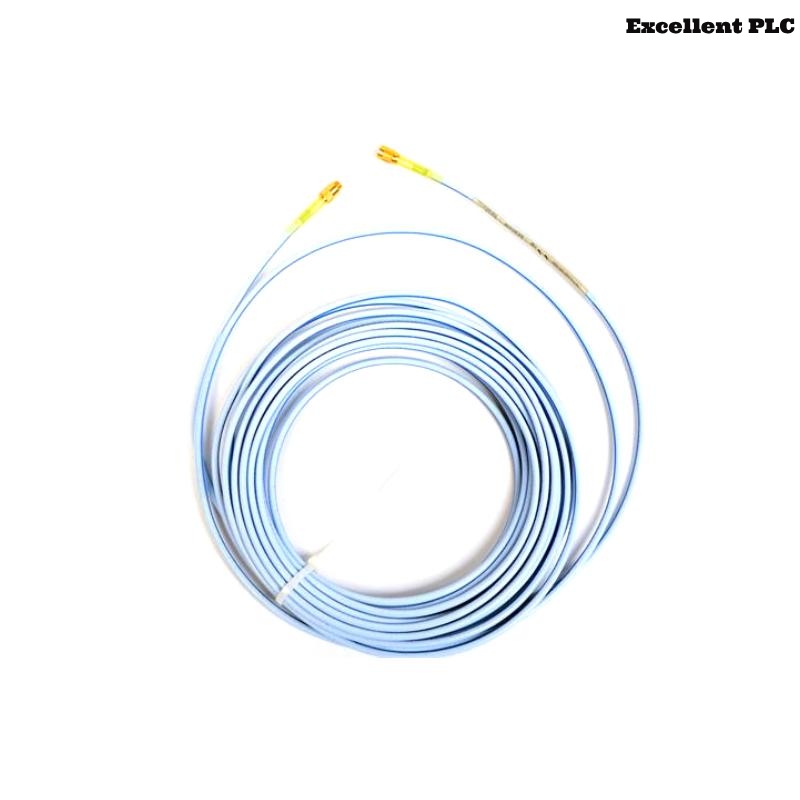

The Bently Nevada 21000-16-05-00-096-00-02 Proximity Probe Housing Assembly is a key component of Bently Nevada’s vibration monitoring system. This robust and precision-engineered assembly is designed to house the proximity probes used for measuring the displacement of rotating machinery components, such as shafts and bearings. With its rugged design and excellent resistance to extreme industrial environments, this housing assembly is essential for industries where vibration monitoring and condition-based maintenance are critical. The 21000-16-05-00-096-00-02 assembly ensures that the proximity probes remain securely mounted and accurately aligned, thereby optimizing the accuracy and reliability of vibration measurement.

Product Specifications:

| Specification | Details |

|---|---|

| Model Number | 21000-16-05-00-096-00-02 |

| Housing Material | Stainless Steel |

| Probe Type | Eddy-current proximity probes |

| Probe Diameter | 0.625 inches (16 mm) |

| Housing Length | 7.5 inches (190 mm) |

| Probe Cable Length |

0.5 m |

| Weight | 1.1 kg |

| Temperature Range | -40°C to +120°C |

| Mounting | Flanged, with standard mounting holes |

| Protection Class | IP67 |

| Vibration Frequency Range | 0 to 1000 Hz |

| Max Pressure | 1500 psi |

| Operating Environment | Harsh industrial environments (wet, high-temp, etc.) |

Applications:

The Bently Nevada 21000-16-05-00-096-00-02 Proximity Probe Housing Assembly is widely used across various industries that require precise and reliable vibration monitoring for their rotating machinery. Its typical applications include:

-

Power Generation: Ensures continuous monitoring of turbine and motor shaft displacement in power plants.

-

Oil and Gas: Used in drilling rigs and pumping stations for real-time detection of mechanical faults in high-speed pumps, compressors, and turbines.

-

Chemical Manufacturing: Used in vibration analysis of critical rotating equipment in chemical production, preventing equipment failure due to imbalances or misalignments.

-

Pulp and Paper Industry: Helps monitor the condition of machines like paper mills and presses, reducing unplanned downtime and maintenance costs.

-

Mining: Used to monitor the health of crushers, mills, and conveyors, contributing to the efficiency of mining operations.

-

Aerospace and Defense: Implements real-time monitoring of rotating components in aircraft engines and military equipment.

Advantages:

-

Durable Construction: Made from high-quality stainless steel, the housing is resistant to corrosion, ensuring a long lifespan in harsh conditions.

-

Accurate Vibration Measurement: The proximity probe housing provides precise mounting and alignment, which enhances the accuracy of vibration monitoring and fault detection.

-

Wide Temperature and Pressure Range: It operates in extreme environments with temperatures from -40°C to +120°C and can withstand pressures up to 1500 psi.

-

Easy Integration: The design of the housing assembly makes it compatible with a wide range of Bently Nevada’s proximity probes and monitoring systems, ensuring seamless integration.

-

IP67 Protection Rating: The housing is dustproof and resistant to immersion in water up to 1 meter, offering superior protection against environmental factors.

-

Reduced Maintenance Costs: By providing early fault detection through precise measurements, this housing assembly helps reduce costly downtime and maintenance for critical machinery.

-

Versatile Applications: The housing is adaptable to various industrial sectors, ensuring its wide use in power generation, oil and gas, and other heavy-duty industries.

Recent News Headlines:

-

“Bently Nevada Introduces Advanced Proximity Probe Housing Assemblies for Reliable Vibration Monitoring”

-

“New Bently Nevada Proximity Probe Housing: A Game Changer for Machine Health Monitoring”

-

“Bently Nevada 21000-16-05-00-096-00-02 Helps Improve Operational Efficiency in Power Plants”

-

“Vibration Monitoring Made Easier with Bently Nevada’s New Proximity Probe Housing Assemblies”

-

“Bently Nevada Boosts Industrial Vibration Monitoring with Durable New Probe Housing Assemblies”

-

“Bently Nevada Unveils Tougher Proximity Probe Housing for Critical Applications in Oil & Gas”

-

“Enhancing Condition Monitoring with Bently Nevada’s Proximity Probe Housing Assemblies”

-

“Bently Nevada’s Latest Housing Assembly Supports Real-Time Vibration Monitoring in Harsh Environments”

Frequently Asked Questions (FAQs)

-

What is the purpose of the Bently Nevada 21000-16-05-00-096-00-02 Proximity Probe Housing Assembly?

This housing assembly is designed to securely mount and protect proximity probes that measure the displacement of rotating machinery components, ensuring precise vibration monitoring.

-

What is the maximum temperature range for this housing assembly?

The housing assembly can withstand temperatures ranging from -40°C to +120°C, making it suitable for use in both extremely cold and hot environments.

-

What materials are used in the construction of this housing assembly?

The housing is constructed from stainless steel, ensuring durability and resistance to corrosion, even in harsh industrial environments.

-

What type of probes are compatible with this housing assembly?

This housing assembly is designed for eddy-current proximity probes, which are commonly used in vibration monitoring systems for rotating machinery.

-

What industries typically use the Bently Nevada 21000-16-05-00-096-00-02?

It is used in industries such as power generation, oil and gas, chemical manufacturing, mining, and pulp and paper, where vibration monitoring of rotating equipment is crucial.

-

How is the housing assembly mounted?

The housing assembly is flanged and includes standard mounting holes for easy integration into existing machinery setups.

-

What is the IP rating of the housing assembly?

The housing assembly has an IP67 protection rating, making it dustproof and resistant to immersion in water up to 1 meter, ensuring reliable operation in harsh environments.

-

What is the maximum pressure the housing can withstand?

The housing is rated to withstand a maximum pressure of 1500 psi, making it suitable for high-pressure environments.

-

How does the Bently Nevada 21000-16-05-00-096-00-02 improve vibration monitoring accuracy?

By securely housing and aligning the proximity probes, this assembly ensures accurate displacement measurement of rotating machinery components, leading to more reliable vibration monitoring.

-

What are the benefits of using this housing assembly in vibration monitoring?

The assembly provides enhanced protection for the proximity probes, ensures accurate measurements, and reduces maintenance costs by detecting faults early, thus minimizing downtime.

Recommended Models

| Model Number | Description | Key Feature |

|---|---|---|

| Bently Nevada 21000-16-05-00-096-00-03 | Proximity Probe Housing Assembly | Enhanced temperature tolerance |

| Bently Nevada 21000-16-05-00-097-00-01 | Proximity Probe Housing Assembly | Suitable for high-speed rotating equipment |

| Bently Nevada 21000-16-05-00-098-00-01 | Proximity Probe Housing Assembly | Designed for chemical manufacturing |

| Bently Nevada 21000-16-05-00-096-00-04 | Heavy Duty Proximity Probe Housing | High-pressure applications |

| Bently Nevada 21000-16-05-00-097-00-02 | Stainless Steel Proximity Probe Housing | Corrosion-resistant for harsh environments |

| Bently Nevada 21000-16-05-00-098-00-02 | Low-Temperature Proximity Probe Housing | Ideal for cold storage applications |

| Bently Nevada 21000-16-05-00-099-00-01 | Compact Proximity Probe Housing | Space-saving design for confined areas |

| Bently Nevada 21000-16-05-00-100-00-01 | Proximity Probe Housing for Turbomachinery | Specialized for turbine and compressor monitoring |

Popular Bently Nevada Models

| Model Number | Description | Key Feature |

|---|---|---|

| Bently Nevada 330130-040-00 | Vibration Transducer | Precision measurement for machinery health |

| Bently Nevada 330100-065-05 | Vibration Monitoring System | Comprehensive monitoring for industrial machinery |

| Bently Nevada 3500/42M | Dynamic Pressure Module | High-performance pressure monitoring |

| Bently Nevada 3300 XL | Proximity Transducer | Accurate displacement measurement |

| Bently Nevada 3500/22M | Vibration Monitoring Module | Multi-channel vibration data collection |

| Bently Nevada 3500/53 | System Monitor | Real-time monitoring and diagnostics |

| Bently Nevada 3300 | Proximity Probe | Precision proximity measurement |

| Bently Nevada 3500/91 | Protection Monitoring System | Fault detection and protective measures |

Excellent PLC

Excellent PLC