| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

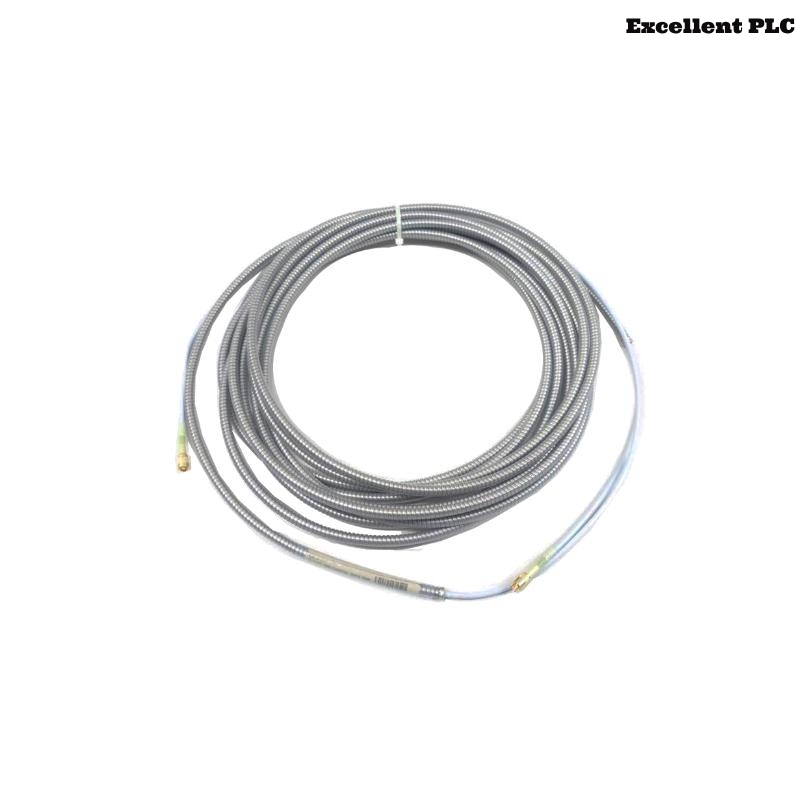

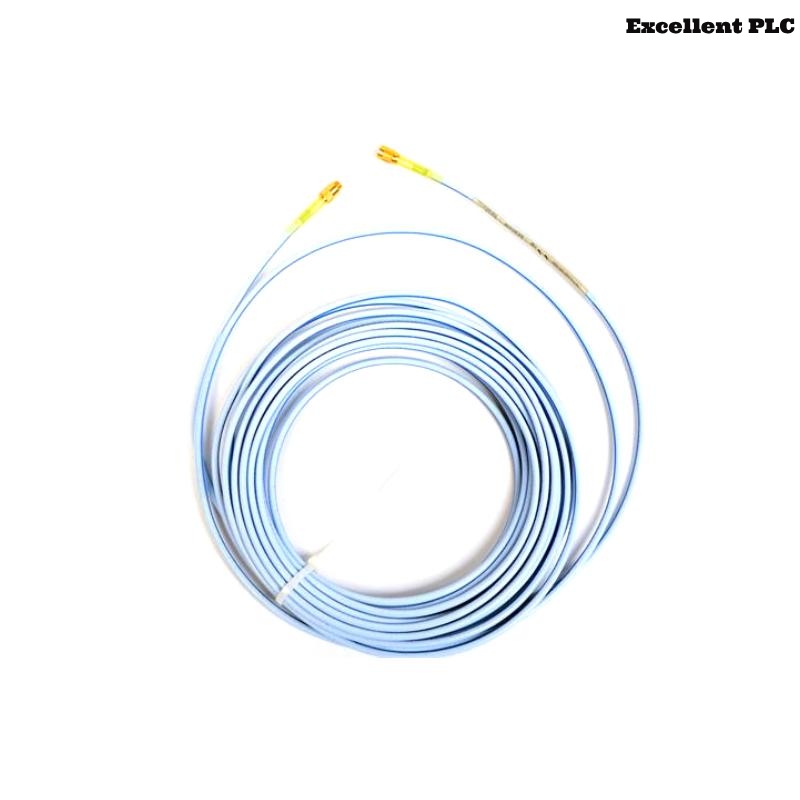

The Bently Nevada 190501-12-00-04 Velomitor CT Velocity Transducer is a high-performance vibration monitoring device designed to measure velocity in rotating machinery. As part of Bently Nevada’s Velomitor series, this transducer provides accurate and reliable velocity measurements for industrial applications, including power generation, oil and gas, and manufacturing.

The 190501-12-00-04 model is built for continuous monitoring of machinery health and provides a direct velocity output, eliminating the need for additional signal processing. It features a rugged stainless-steel housing, which ensures durability in harsh environments. The wide frequency range allows for monitoring low to high-speed rotating equipment, making it a critical component in predictive maintenance programs.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | 190501-12-00-04 |

| Measurement Type | Velocity |

| Sensitivity | 100 mV/in/s |

| Frequency Response | 10 Hz to 8 kHz |

| Output Signal | ±10V DC |

| Operating Temperature | -40°C to +85°C |

| Power Supply | 18-30V DC |

| Housing Material | Stainless Steel |

| Weight | 0.297 kg |

| Sensor Head Diameter | 33 mm |

| Mounting | Threaded Stud or Adhesive |

| Cable Length | Customizable |

Product Applications

The Bently Nevada 190501-12-00-04 Velomitor CT Velocity Transducer is widely used in industrial applications where vibration monitoring is critical. Some key application areas include:

- Power Generation – Used in gas turbines, steam turbines, and hydroelectric generators to monitor machine health.

- Oil and Gas – Ideal for compressors, pumps, and drilling equipment in refineries and offshore platforms.

- Petrochemical Plants – Helps in monitoring rotating equipment for early failure detection.

- Manufacturing Industry – Ensures optimal performance of motors, gearboxes, and fans.

- Mining Industry – Used in conveyor systems, crushers, and other heavy-duty equipment.

- Aerospace & Defense – Helps in monitoring engines and auxiliary systems in aircraft and defense machinery.

Product Advantages

- High Sensitivity & Accuracy – Provides precise velocity measurement, ensuring early fault detection.

- Wide Frequency Response – Covers a broad range of machinery operating speeds.

- Rugged and Durable Design – Stainless-steel housing offers resistance to harsh industrial environments.

- Direct Velocity Output – Reduces the need for additional signal processing equipment.

- Compact & Lightweight – Allows for easy installation in tight spaces.

- Long-Term Stability – Designed to provide reliable performance over extended periods.

- Customizable Cable Lengths – Offers flexibility in installation.

- Industry-Standard Mounting Options – Compatible with threaded studs and adhesive mounting.

Latest News Headlines

- “Bently Nevada Expands Velomitor Series for Enhanced Industrial Monitoring”

- “190501-12-00-04 Transducer: A Breakthrough in Predictive Maintenance”

- “How Velocity Transducers are Transforming Industrial Vibration Monitoring”

- “New Developments in Machinery Protection: The Role of Bently Nevada Sensors”

- “Optimizing Power Plant Efficiency with Bently Nevada’s Advanced Sensors”

- “Improved Reliability in Oil & Gas Operations with 190501-12-00-04 Velomitor CT”

- “Preventing Unplanned Downtime: The Importance of Real-Time Vibration Monitoring”

- “Innovations in Sensor Technology: The Evolution of Velocity Transducers”

Frequently Asked Questions (FAQ)

-

What is the main function of the Bently Nevada 190501-12-00-04 Velomitor CT?

- It is designed to monitor velocity in rotating machinery to detect vibration-related faults early.

-

What is the sensitivity of this transducer?

- The sensitivity is 100 mV/in/s, making it highly accurate for velocity measurements.

-

What types of machines can this transducer monitor?

- It is commonly used for turbines, compressors, pumps, motors, fans, and gearboxes.

-

Can the 190501-12-00-04 withstand harsh environments?

- Yes, its stainless-steel housing ensures durability in industrial and outdoor environments.

-

Does this sensor require additional signal processing?

- No, it provides a direct velocity output, eliminating the need for additional processing.

-

How is this transducer mounted?

- It can be mounted using a threaded stud or adhesive for secure placement.

-

What is the operating temperature range?

- It operates between -40°C to +85°C, making it suitable for extreme conditions.

-

Is the cable length customizable?

- Yes, it can be customized to meet specific installation requirements.

-

What is the frequency response range?

- It covers a range of 10 Hz to 8 kHz, allowing for monitoring across various machine speeds.

-

What industries typically use this transducer?

- Industries such as power generation, oil & gas, petrochemical, manufacturing, mining, and aerospace utilize this sensor.

Related Models (Same Series or Similar Category)

| Model Number | Sensitivity | Frequency Range | Output Signal |

|---|---|---|---|

| 190501-12-00-04 | 100 mV/in/s | 10 Hz to 8 kHz | ±10V DC |

| 190501-04-00-00 | 80 mV/in/s | 10 Hz to 8 kHz | ±10V DC |

| 190501-00-05-10 | 100 mV/in/s | 5 Hz to 10 kHz | ±10V DC |

| 190501-01-00-00 | 50 mV/in/s | 10 Hz to 6 kHz | ±10V DC |

| 330500-02-00 | 100 mV/in/s | 5 Hz to 10 kHz | ±10V DC |

| 330500-02-01 | 80 mV/in/s | 10 Hz to 8 kHz | ±10V DC |

| 991-01-XX-01-00 | 70 mV/in/s | 8 Hz to 9 kHz | ±10V DC |

| 991-02-XX-02-00 | 90 mV/in/s | 6 Hz to 9.5 kHz | ±10V DC |

Popular Models from Bently Nevada

| Model Number | Type |

|---|---|

| 330104-00-20-10-02-05 | Proximity Probe |

| 330850-90-05 | Accelerometer |

| 3500/42M | Proximitor Seismic Module |

| 3500/22M | Data Acquisition Module |

| 330400 | Eddy Current Probe |

| 330780 | Velocity Sensor |

| 2300/20 | Vibration Monitor |

| 3500/50M | Tachometer Module |

Excellent PLC

Excellent PLC