| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

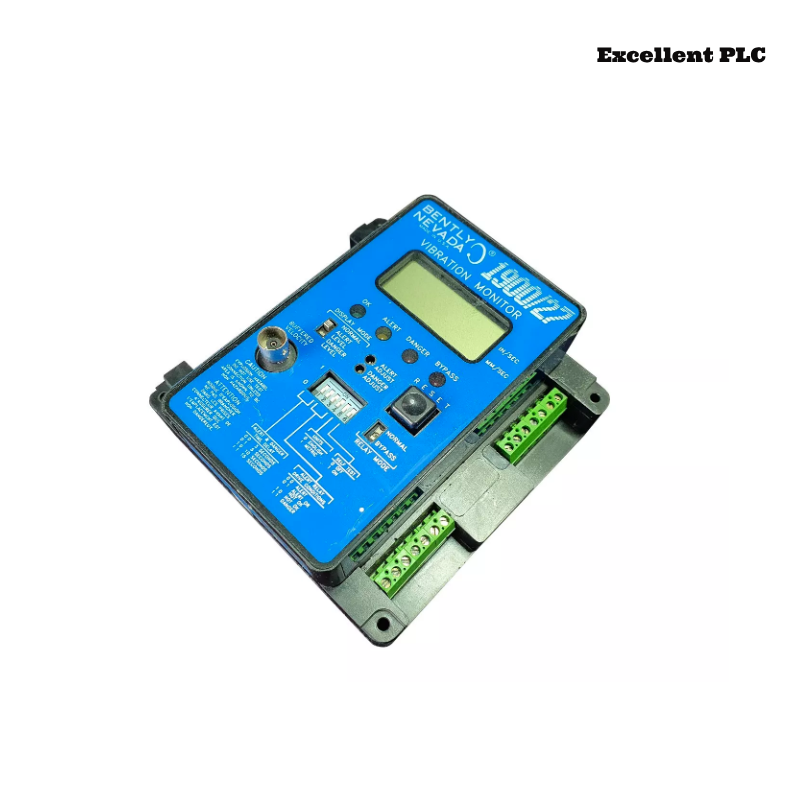

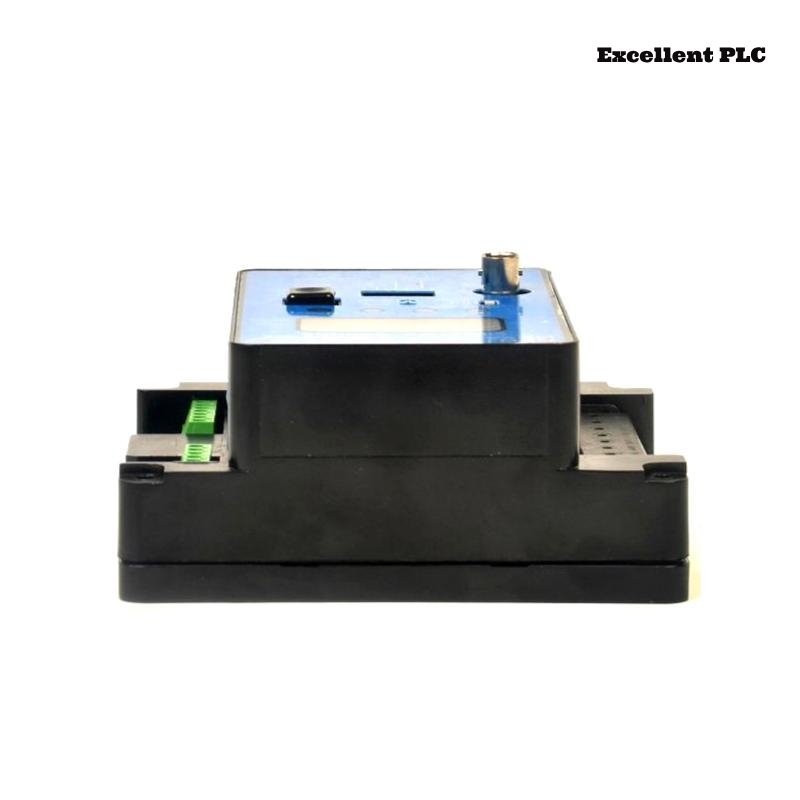

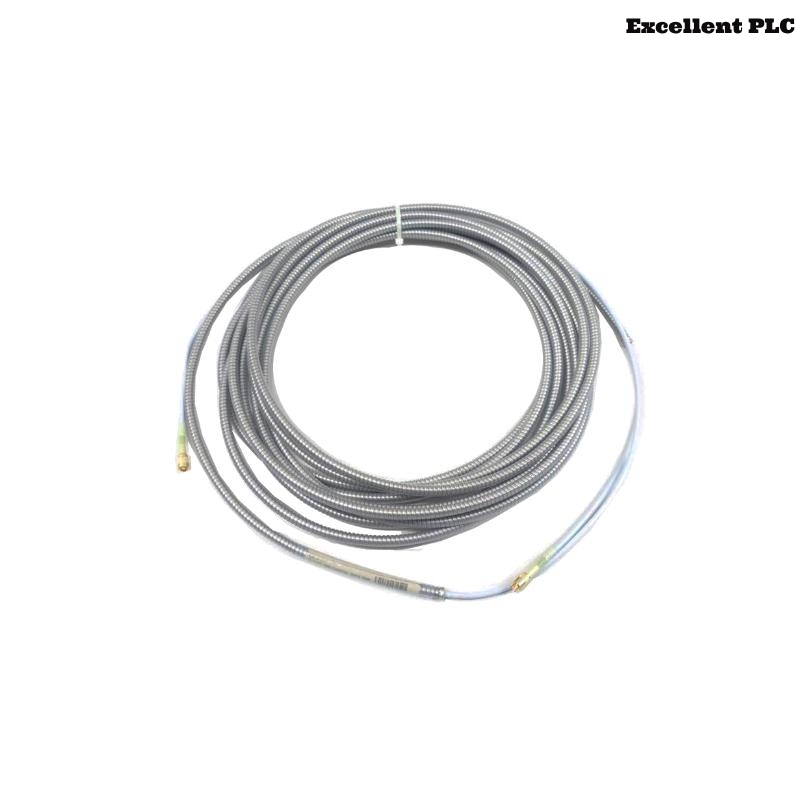

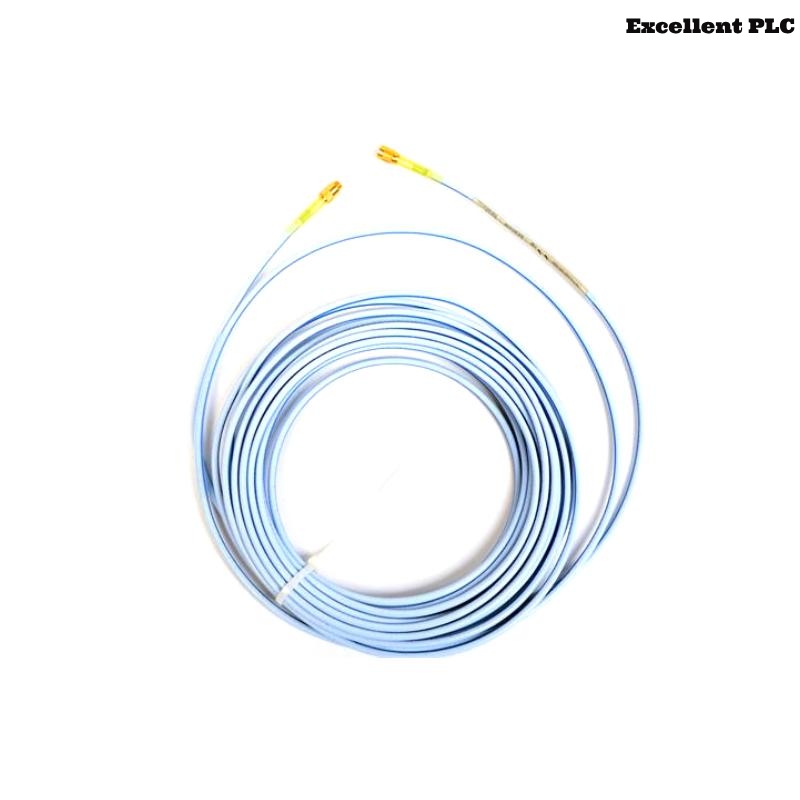

The Bently Nevada 1900/27-03 Vibration Monitor is a compact yet powerful vibration monitoring solution designed for continuous machinery protection. Developed by Bently Nevada, a leader in condition monitoring technology, this device provides real-time vibration analysis and alarming, ensuring critical rotating machinery operates reliably and efficiently.

Designed for industries such as power generation, oil and gas, manufacturing, and heavy machinery, the 1900/27-03 model helps prevent costly equipment failures by identifying early signs of imbalance, misalignment, bearing wear, or structural issues. Its advanced data processing capabilities, flexible communication options, and robust construction make it a top choice for predictive maintenance programs.

Product Specifications

The table below presents the detailed technical specifications for the Bently Nevada 1900/27-03 Vibration Monitor:

| Parameter | Specification |

|---|---|

| Product Type | Vibration Monitor |

| Model Number | 1900/27-03 |

| Measurement Parameters | Acceleration, Velocity, Displacement |

| Measurement Frequency Range | 0.1 Hz to 10 kHz |

| Output Type | Analog (4-20 mA), Digital (Modbus RTU) |

| Alarming Functions | Configurable alarm thresholds |

| Display | LED indicators for alarm status |

| Power Supply | 24V DC ±20% |

| Operating Temperature | -10°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Mounting Type | DIN Rail Mountable |

| Communication Protocols | Modbus RTU, 4-20 mA output |

| Protection Rating | IP20 |

| Housing Material | Industrial-grade metal enclosure |

| Certification | CE, UL, RoHS |

| Dimensions (L x W x H) | 132 x 132 x 71.1 mm |

| Weight | 0.4 kg |

Product Applications

The Bently Nevada 1900/27-03 Vibration Monitor is widely used in industries that rely on rotating equipment. Below are some key applications:

- Power Generation: Monitoring turbines, generators, and cooling fans to detect early signs of mechanical failure.

- Oil & Gas Industry: Ensuring continuous operation of compressors, pumps, and drilling equipment to prevent costly downtimes.

- Manufacturing & Processing Plants: Keeping track of motor vibrations in conveyor belts, presses, and heavy machinery.

- Mining & Metal Processing: Protecting crushers, mills, and vibrating screens from excessive wear and tear.

- Petrochemical Industry: Monitoring rotating equipment in refineries and chemical plants to ensure smooth operation.

Product Advantages

The Bently Nevada 1900/27-03 Vibration Monitor offers numerous advantages that make it a preferred choice for industrial applications:

Early Fault Detection: Helps detect mechanical issues like imbalance, misalignment, and bearing defects before they lead to failures.

Real-Time Monitoring: Provides continuous monitoring of machinery vibration levels with instant alarm notifications.

Flexible Communication Options: Supports Modbus RTU and 4-20 mA outputs for seamless integration with existing control systems.

Compact and Robust Design: Small form factor with industrial-grade build quality ensures durability in harsh environments.

Customizable Alarm Thresholds: Users can define alarm limits to suit specific operational conditions.

Energy Efficient: Consumes minimal power while delivering high-precision vibration monitoring.

DIN Rail Mountable: Simplifies installation in industrial control panels.

Reduces Maintenance Costs: Enables predictive maintenance strategies that minimize unexpected breakdowns and costly repairs.

Latest News

- “Bently Nevada Introduces Enhanced Vibration Monitoring for Heavy Industry”

- “How the 1900/27-03 is Revolutionizing Predictive Maintenance”

- “Preventing Equipment Failures with the Latest Bently Nevada Vibration Monitor”

- “The Future of Condition Monitoring: Bently Nevada’s 1900 Series”

- “How Real-Time Vibration Monitoring Saves Millions in Industrial Maintenance”

- “Bently Nevada Expands Its Portfolio with Advanced Monitoring Solutions”

- “Reducing Downtime with the 1900/27-03: A Case Study”

- “Maximizing Machine Lifespan with Predictive Vibration Monitoring”

- “Why Bently Nevada’s Vibration Monitors Are the Industry Standard”

- “Smart Monitoring Solutions: The Key to Improved Operational Efficiency”

Frequently Asked Questions (FAQ)

-

What is the main purpose of the Bently Nevada 1900/27-03?

It is designed to continuously monitor vibration levels in rotating machinery, helping prevent mechanical failures and unexpected downtimes. -

What types of equipment can it monitor?

It is suitable for monitoring motors, pumps, turbines, compressors, fans, and other rotating assets. -

What output options does it support?

The device offers analog 4-20 mA outputs as well as digital communication via Modbus RTU. -

Can I configure alarm thresholds?

Yes, users can set custom alarm thresholds for vibration levels to trigger alerts when limits are exceeded. -

What is the operating temperature range?

The device can function in temperatures between -10°C and +60°C. -

How is the unit powered?

It operates on a 24V DC power supply with a ±20% tolerance. -

Is the monitor easy to install?

Yes, it features a DIN rail mounting design for quick and simple installation. -

Does it have any environmental certifications?

Yes, it meets CE, UL, and RoHS standards. -

Can it be integrated into existing industrial control systems?

Absolutely. It supports Modbus RTU for seamless integration with SCADA, PLC, and DCS systems. -

How does it help reduce maintenance costs?

By providing early fault detection, it enables predictive maintenance, reducing the need for emergency repairs and extending the lifespan of equipment.

Related Models

| Model Number | Description | Measurement Type | Output Type |

|---|---|---|---|

| 1900/27-01 | Standard vibration monitor for rotating assets | Velocity, Acceleration | 4-20 mA, Modbus RTU |

| 1900/27-02 | Advanced model with expanded measurement range | Acceleration, Displacement | 4-20 mA, Modbus RTU |

| 3500/22M | Enhanced vibration monitor for high-speed assets | Velocity, Displacement | Modbus RTU, 4-20 mA |

| 3500/25 | Machinery protection system with vibration sensing | Acceleration | 4-20 mA |

| 3500/40M | Advanced vibration and position monitoring system | Velocity, Displacement | Modbus RTU |

| 3500/42 | Multi-channel vibration monitoring system | Acceleration, Velocity | 4-20 mA |

| 330500-01 | Compact vibration monitoring for motors | Acceleration | 4-20 mA |

| 330100-00 | Simple monitoring solution for non-critical machines | Velocity | 4-20 mA |

| 3300/15 | Entry-level vibration monitor for industrial use | Displacement, Acceleration | 4-20 mA |

| 330700-01 | Advanced vibration analysis unit | Peak, RMS | 4-20 mA |

Popular Models

| Model Number | Description | Measurement Type | Output Type |

|---|---|---|---|

| 2300/20 | Dual-channel vibration monitor for machinery | Acceleration, Velocity | Modbus RTU, 4-20 mA |

| 2300/25 | Compact vibration monitoring system for rotating assets | Displacement, Acceleration | 4-20 mA |

| 3500/32M | Advanced vibration and temperature monitoring | Velocity, Temperature | Modbus, 4-20 mA |

| 3500/50 | Advanced machine condition monitoring | Acceleration, Displacement | 4-20 mA, Modbus RTU |

| 3701/55 | Distributed vibration and condition monitoring | Velocity, Acceleration | Modbus RTU |

| 3700/40 | Condition monitoring system for critical assets | Acceleration, Displacement | 4-20 mA |

| 330180-90-00 | High-performance vibration sensor | Acceleration | 4-20 mA |

| 330850-50-05 | Wireless vibration monitoring for industrial machines | Acceleration | Wireless, Modbus |

| 330100-90-00 | Ruggedized vibration monitoring unit | Velocity | 4-20 mA |

| 3300/12 | High-precision monitoring for industrial equipment | Displacement, Velocity | 4-20 mA |

Excellent PLC

Excellent PLC