| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

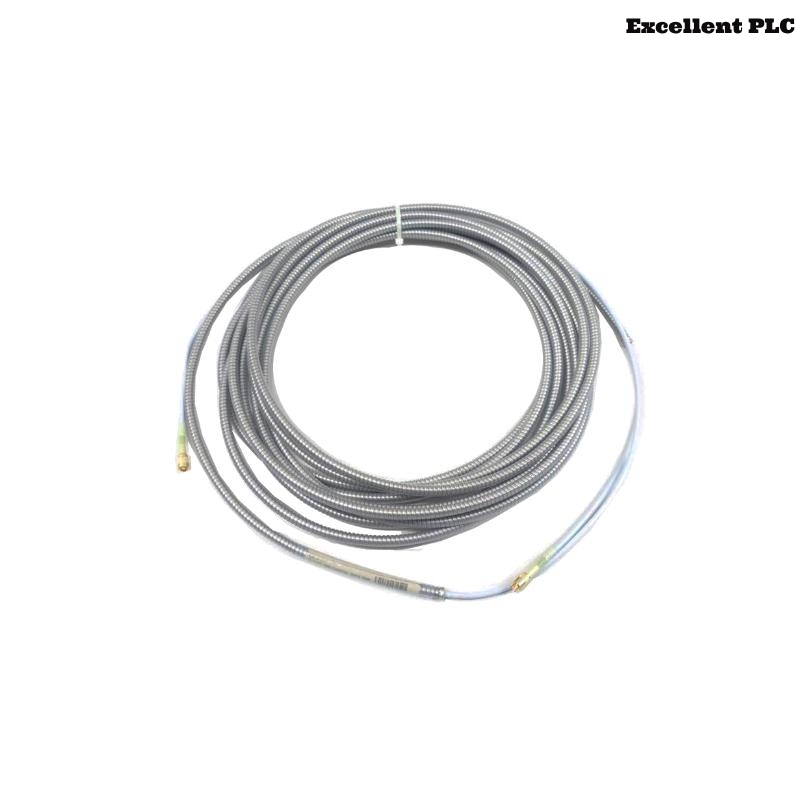

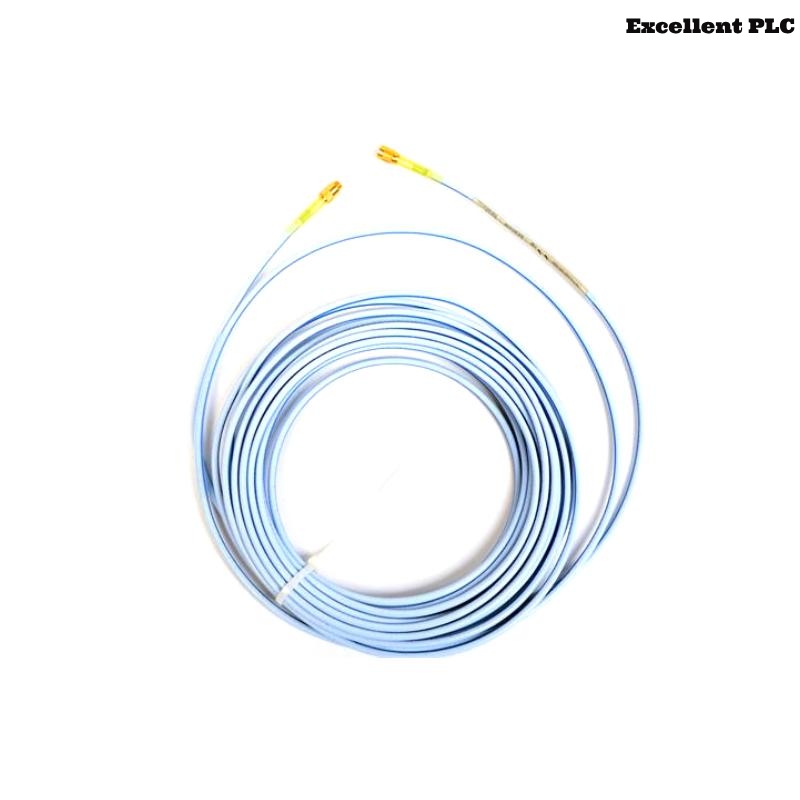

The Bently Nevada 177230-00-01-05 Seismic Transmitter is a high-precision vibration and seismic monitoring device designed to detect ground movement, structural vibrations, and machine instability. This transmitter integrates an advanced seismic sensor with an intelligent signal processing unit, enabling accurate real-time monitoring in critical industrial environments.

Engineered for durability and reliability, the 177230-00-01-05 is built to withstand harsh operating conditions, including extreme temperatures, heavy vibrations, and corrosive environments. The transmitter is widely used in industries such as oil and gas, power generation, and heavy machinery, where precise vibration monitoring is essential for safety and operational efficiency.

By converting seismic activity into a standardized output signal (4-20mA), the transmitter ensures easy integration with industrial control systems and condition monitoring platforms. This helps facilities proactively detect anomalies, prevent equipment failures, and enhance overall system reliability.

Product Specifications

| Parameter | Details |

|---|---|

| Model | Bently Nevada 177230-00-01-05 |

| Measurement Type | Seismic Vibration |

| Output Signal | 4-20 mA |

| Power Supply | 12V to 30V DC |

| Frequency Range | 0.1 Hz – 450 Hz |

| Operating Temperature | -40°C to +85°C |

| Humidity | 0% – 95% RH (Non-condensing) |

| Shock Resistance | 5000 g |

| Mounting | Bolt-on or Adhesive |

| Housing Material | Stainless Steel |

| Ingress Protection | IP67 |

| Sensor Head Diameter | 25.4 mm |

| Weight | 0.131 kg |

Applications

-

Structural Health Monitoring

- Used in buildings, bridges, and industrial structures to monitor vibrations and detect potential structural weaknesses.

-

Machinery Condition Monitoring

- Ideal for monitoring turbines, compressors, and rotating equipment to prevent excessive vibration and mechanical failures.

-

Seismic Activity Detection

- Deployed in seismic-sensitive locations such as oil rigs, dams, and power plants to detect ground movement and vibrations.

-

Energy Sector Applications

- Utilized in nuclear, thermal, and hydro power plants to ensure operational safety and stability.

-

Pipeline Monitoring

- Helps in identifying unexpected vibrations that could indicate leaks, pressure surges, or pipeline integrity issues.

Advantages

-

High Sensitivity and Accuracy

- Offers precise vibration measurements with a broad frequency range to detect even the slightest movements.

-

Durable and Reliable Design

- Stainless steel housing with IP67 protection ensures the transmitter operates reliably in extreme environments.

-

Seamless Integration

- 4-20 mA output makes it compatible with most industrial control systems and monitoring platforms.

-

Low Maintenance

- Designed for long-term operation with minimal recalibration or servicing requirements.

-

Early Warning System

- Provides real-time alerts and trend data, allowing proactive maintenance and reducing downtime.

Latest News Headlines

- “Bently Nevada Expands Seismic Monitoring Solutions with Advanced 177230 Series”

- “How Bently Nevada’s Seismic Transmitters Are Enhancing Industrial Safety”

- “Oil and Gas Sector Adopts Bently Nevada 177230-00-01-05 for Critical Monitoring”

- “Structural Engineers Leverage Bently Nevada Sensors for Earthquake Resilience”

- “Predictive Maintenance Revolution: Bently Nevada 177230-00-01-05 in Action”

Frequently Asked Questions (FAQ)

-

What is the primary function of the Bently Nevada 177230-00-01-05 Seismic Transmitter?

- The transmitter is designed to measure seismic and structural vibrations, providing continuous real-time data for machinery protection and structural integrity assessment.

-

What type of signal output does this transmitter provide?

- The device outputs a standard 4-20 mA signal, which is widely used in industrial monitoring systems for seamless integration with SCADA and DCS platforms.

-

What is the frequency response range of this transmitter?

- The frequency range of the Bently Nevada 177230-00-01-05 is 0.1 Hz to 450 Hz, making it suitable for detecting both low-frequency seismic activities and higher-frequency mechanical vibrations.

-

What environmental conditions can this transmitter withstand?

- The unit operates effectively in temperatures ranging from -40°C to +85°C, with an IP67-rated stainless steel housing, ensuring resistance to dust, moisture, and harsh industrial conditions.

-

How does the transmitter ensure measurement accuracy in industrial applications?

- It incorporates precision signal conditioning and low-noise circuitry to provide stable and accurate vibration data, minimizing interference from external factors such as electrical noise and mechanical disturbances.

-

What kind of power supply does the transmitter require?

- The unit operates on a DC voltage range of 12V to 30V, allowing compatibility with most industrial power systems without requiring additional voltage conversion.

-

What are the primary industrial applications of this transmitter?

- The transmitter is used in oil and gas facilities, power plants, rotating machinery, and infrastructure monitoring, particularly for detecting excessive vibrations that could indicate early-stage equipment failures.

-

What mounting options are available for this seismic transmitter?

- It can be securely mounted using bolt-on or adhesive installation methods, depending on the application and surface type, ensuring optimal contact for precise vibration measurements.

-

How often does the device require calibration or maintenance?

- The Bently Nevada 177230-00-01-05 is designed for long-term stability, with minimal drift over time. However, periodic calibration (typically every 12 to 24 months) is recommended to ensure peak performance.

-

Can this transmitter be used in offshore and hazardous environments?

- Yes, its rugged design, high shock resistance (5000g), and corrosion-resistant materials make it suitable for offshore platforms, marine environments, and hazardous industrial zones.

Related Models in the Same Series

| Model Number | Description | Measurement Type | Output Signal | Application |

|---|---|---|---|---|

| 177230-00-01-06 | Seismic Transmitter | Vibration | 4-20 mA | Machinery Protection |

| 330400 | Seismic Sensor | Acceleration | 100 mV/g | Structural Health |

| 330425 | Vibration Monitor | Velocity | 4-20 mA | Industrial Equipment |

| 108M1332 | Acceleration Sensor | Acceleration | Voltage Output | Seismic Detection |

| 330103 | Vibration Transmitter | Vibration | 4-20 mA | Condition Monitoring |

| 330180 | Piezoelectric Sensor | Acceleration | Voltage | Rotating Equipment |

| 330104 | Velocity Transmitter | Velocity | 4-20 mA | Predictive Maintenance |

| 330130 | Seismic Monitor | Displacement | Digital | Structural Integrity |

| 990-05-70-01-00 | Seismic Protection System | Multi-axis | Digital | Infrastructure Monitoring |

| 3701/55 | Vibration Monitor | Multi-channel | Digital | High-risk Environments |

Popular Bently Nevada Models

| Model Number | Description | Key Feature | Application |

|---|---|---|---|

| 3500/22M | Proximitor Monitor | High-Speed Data Processing | Machinery Monitoring |

| 3300 XL | Proximity Probe | High Accuracy | Rotating Equipment |

| 2300 Series | Vibration Monitor | Dual-channel | Pumps and Fans |

| ADRE 408 | Data Acquisition System | Multi-Channel | Rotating Machinery |

| 3500/42M | Proximitor Monitor | Modular Design | Condition Monitoring |

| 190501 | Acceleration Sensor | Low Noise | Structural Monitoring |

| 3500/92 | Communication Gateway | Multi-protocol Support | Industrial Networks |

| 330780 | Proximity Probe | Compact Design | Turbomachinery |

| 990-05-70-01-00 | Vibration Protection System | Multi-axis Detection | Large-Scale Machinery |

| System 1 | Condition Monitoring Software | Advanced Analytics | Predictive Maintenance |

Excellent PLC

Excellent PLC