| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

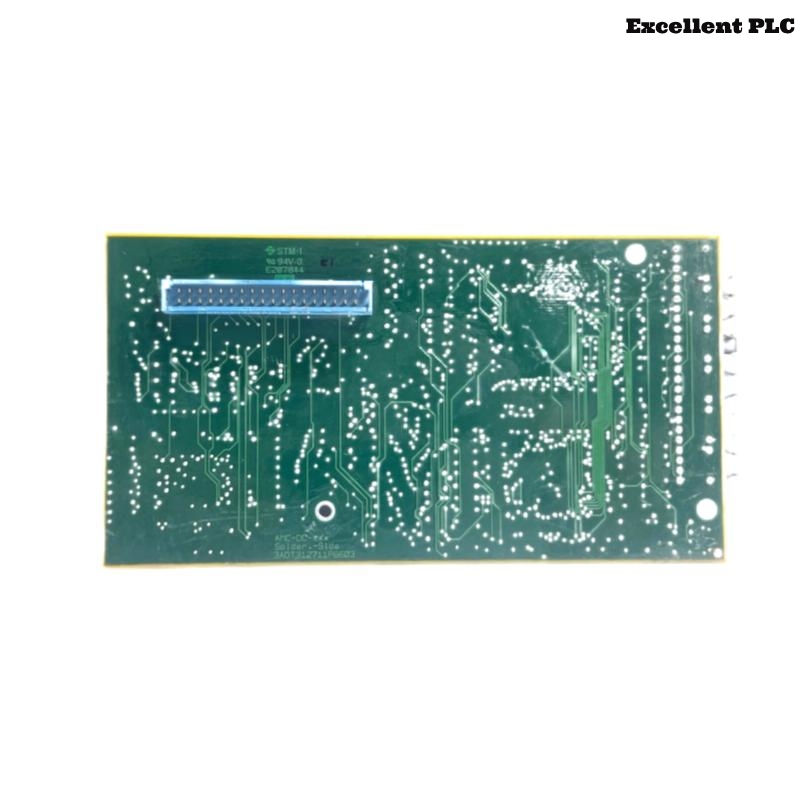

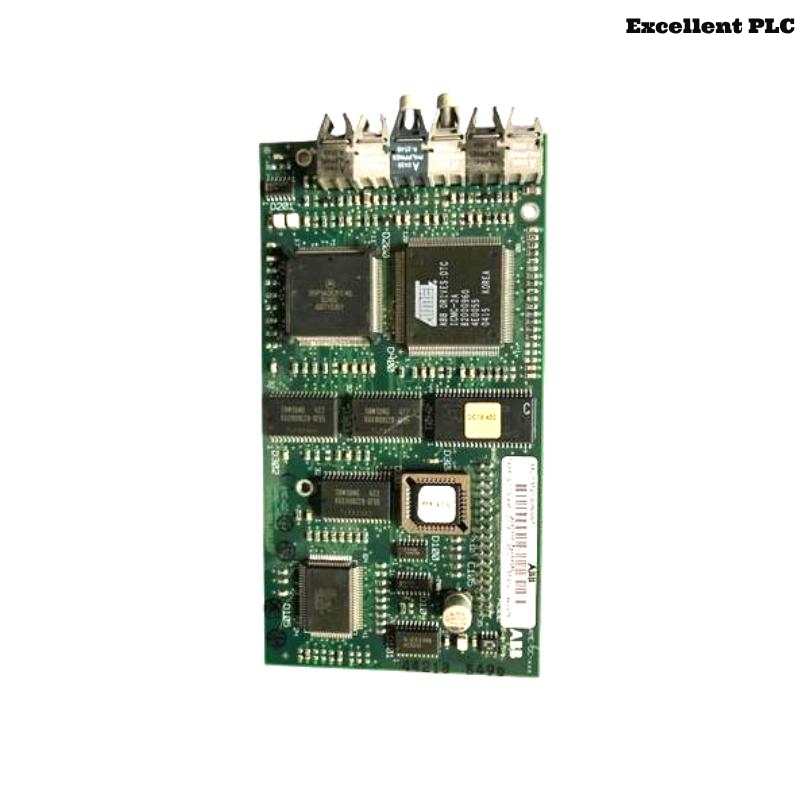

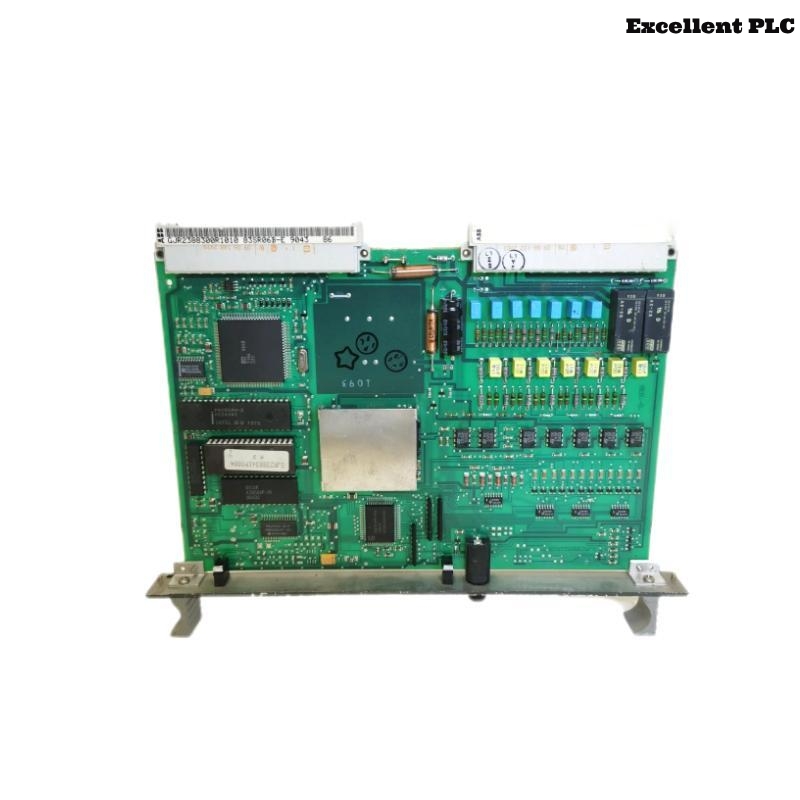

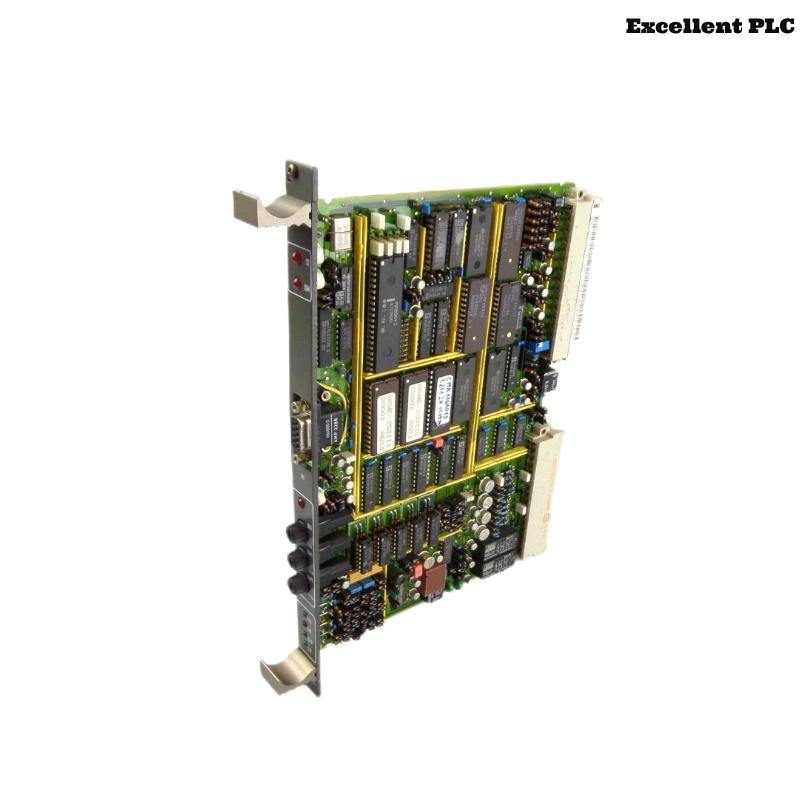

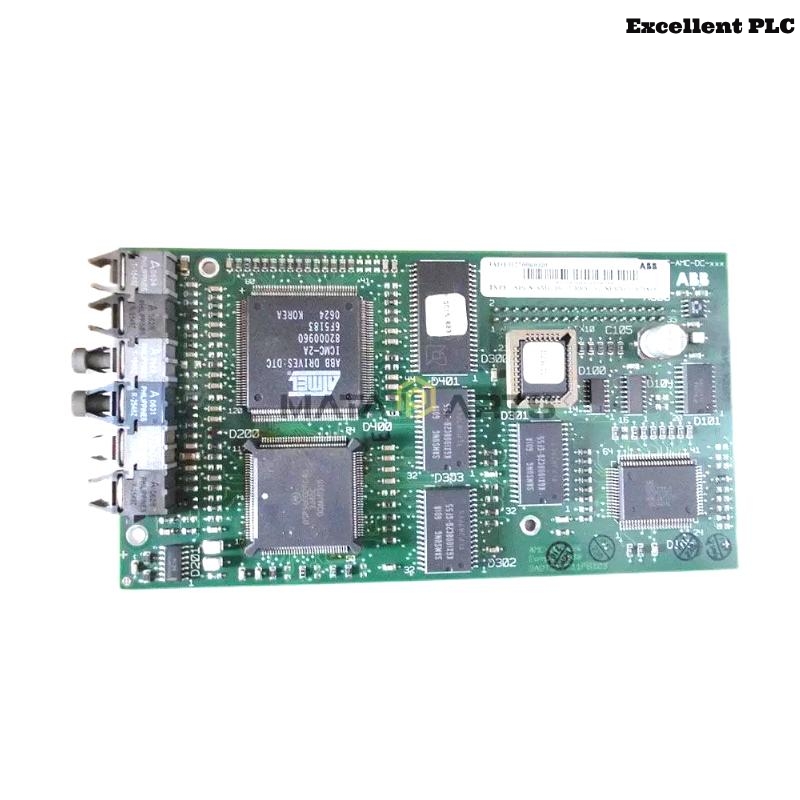

The ABB SDCS-AMC-DC is a critical control module designed for use in ABB’s high-performance DC drive systems. As part of ABB’s DCS series of drives, this board functions as the main control unit, orchestrating various operational parameters such as current control, voltage regulation, field control, and drive protection logic. It represents the heart of the drive’s control system.

The board is equipped with advanced signal processing capabilities and integrates seamlessly into ABB’s DCS500 and DCS800 DC drive systems. Engineered to perform under industrial stress, the SDCS-AMC-DC provides long-term reliability, comprehensive diagnostic support, and high-precision control functionalities. Its design allows it to serve not only in newly developed automation systems but also as a trusted replacement in existing legacy installations.

Technical Specifications

| Parameter | Specification |

|---|---|

| Product Name | SDCS-AMC-DC |

| Manufacturer | ABB |

| Product Type | DC Drive Control Board |

| Compatible Drive Systems | DCS500, DCS800 |

| Input Voltage | 24 VDC nominal |

| Processor Core | Digital Signal Processor (DSP) based |

| Communication Interfaces | Fiber Optic, Serial (RS232/485), CAN (in some versions) |

| Feedback Compatibility | Tachogenerator, Encoder, Armature feedback |

| Operating Temperature Range | 0°C to +55°C |

| Storage Temperature Range | -25°C to +70°C |

| Humidity Rating | <95%, non-condensing |

| Protection Rating | Enclosed within drive system enclosure |

| Board Dimensions (L x W x H) | 235 x 145 x 30 mm |

| Weight | 0.42 kg |

| Installation Orientation | Horizontally mounted inside drive cabinet |

| Compliance | CE, RoHS, UL (region-specific) |

| Typical Lifecycle | >10 years under normal industrial operating conditions |

Product Applications

The SDCS-AMC-DC control board is widely deployed in demanding industrial environments, providing core logic for DC drive operations. Common application sectors include:

-

Steel and Metal Rolling Mills – for large DC motor control in rolling, cutting, and shaping.

-

Pulp & Paper Plants – driving press sections and winders where speed and torque accuracy are crucial.

-

Power Generation Facilities – controlling exciter and auxiliary systems.

-

Cement Production – managing conveyor drives, kiln drives, and mill drives.

-

Mining and Heavy Industry – used in hoists, crushers, and winch applications.

-

Marine Systems – in propulsion control systems and heavy-duty onboard automation.

Product Advantages

-

Robust Control Capabilities: Provides core control logic for high-power DC motors.

-

Flexible Feedback Options: Supports multiple feedback types including encoder, tachogenerator, and armature feedback.

-

Long-Term Availability: Designed for longevity in demanding industrial environments.

-

Integrated Safety: Includes protection logic against overcurrent, undervoltage, and communication failure.

-

Service-Friendly Design: Clearly labeled terminals and modular design simplify installation and replacement.

-

Global Support: Supported by ABB’s worldwide network for servicing, diagnostics, and upgrades.

Frequently Asked Questions (FAQ)

-

What does the SDCS-AMC-DC board control?

It controls the main drive functions such as motor current, voltage regulation, speed feedback, and safety interlocks. -

Which drive systems support this board?

It is compatible with ABB’s DCS500 and DCS800 drive systems. -

Is this board suitable for both old and new systems?

Yes, it can be used in legacy upgrades as well as new installations. -

Can I use encoder feedback with this board?

Yes, the board supports encoder, tacho, and armature feedback. -

Does it require any special cooling?

No, it is passively cooled within the drive enclosure; however, adequate airflow is necessary. -

Is the SDCS-AMC-DC board field-upgradable?

Firmware upgrades are possible through ABB service tools in some versions. -

Can this board be used in regenerative drive applications?

Yes, it’s suitable for regenerative applications when integrated with appropriate components. -

What kind of communication interfaces are available?

Fiber optic, RS232, and optionally CAN bus interfaces are supported. -

How should the board be mounted?

It must be installed horizontally inside the ABB drive enclosure. -

What are the signs of a failing SDCS-AMC-DC board?

Symptoms include erratic motor behavior, communication faults, or failure to initialize the drive.

Related Models (Same Series or Functionality)

| Model | Description | Compatible Drives |

|---|---|---|

| SDCS-AMC-DC-2 | Newer revision with enhanced diagnostics | DCS800 |

| SDCS-CON-2 | Communication interface board | DCS500, DCS800 |

| SDCS-FEX-2 | Fiber optic expansion module | DCS Drives |

| SDCS-COM-81 | Communication board with fieldbus options | DCS800 |

| SDCS-POW-1 | Power board supplying logic and sensors | DCS Drives |

| SDCS-PIN-41 | Analog/Digital input interface | DCS800 |

Popular ABB Control Modules (Same Brand, High Demand)

| Model | Description | Application Field |

|---|---|---|

| PM866K01 | CPU module for AC 800M | ABB 800xA DCS |

| CI870K01 | Fieldbus communication interface | System 800xA / Freelance |

| DO820 | Digital output module (16 channels) | Industrial I/O applications |

| AI835 | Analog input module (8 channels, HART) | Process Automation Systems |

| PM891 | High-performance CPU for safety systems | Functional Safety Automation |

| REF620 | Feeder protection relay | Substation Protection |

Excellent PLC

Excellent PLC