| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

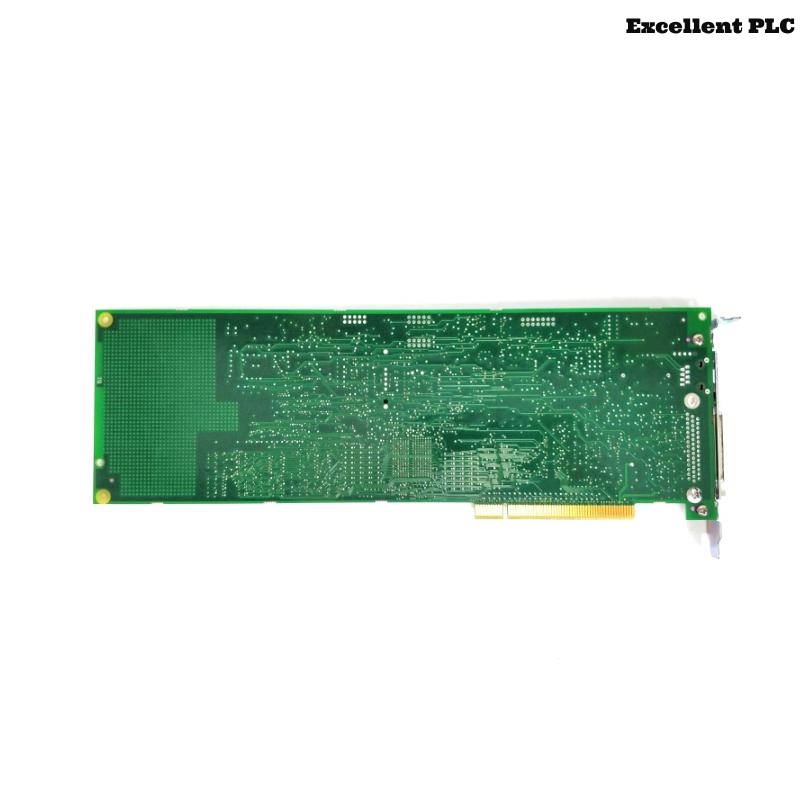

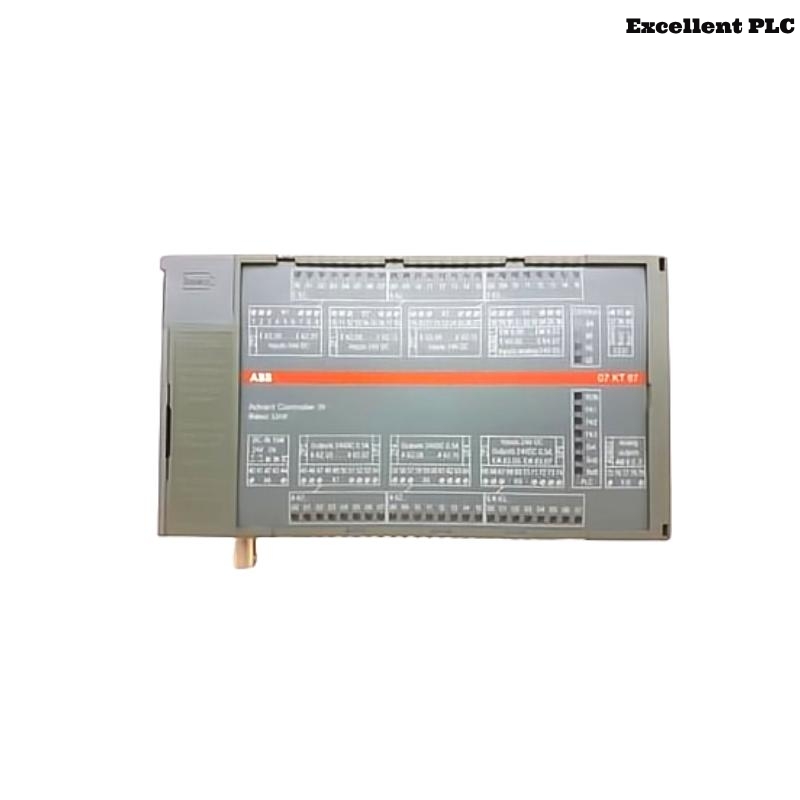

The ABB DSQC 532B 3HAC023447-001 I/O Computer is a high-performance industrial communication and control interface module designed for integration with ABB’s advanced robotic systems. As part of the ABB DSQC (Drive System Quality Controller) series, this module plays a critical role in the communication infrastructure between robot controllers and external devices such as sensors, actuators, and PLCs. It provides multiple input/output interfaces and ensures high-speed data exchange with precise synchronization and real-time performance. Built to withstand industrial environments, this unit is known for its reliability, compact design, and ease of integration.

This I/O computer module is typically installed within the control cabinet of ABB robot systems, especially in applications that require seamless interaction between the robotic brain and field devices. Whether in automated assembly lines, packaging systems, or process control, the DSQC 532B delivers robust functionality to meet the demands of modern automation.

Product Specifications

| Parameter | Specification |

|---|---|

| Product Name | DSQC 532B I/O Computer |

| Product Code | 3HAC023447-001 |

| Manufacturer | ABB |

| Series | DSQC Series |

| Function | I/O interface controller for industrial robots |

| Input/Output Support | Digital & Analog I/O |

| Interface Type | Fieldbus (e.g., Profibus, DeviceNet) |

| Communication Protocols | TCP/IP, Ethernet, Fieldbus |

| Supported Robots | ABB IRC5 series and other compatible units |

| Operating Temperature | 0°C to +55°C |

| Storage Temperature | -25°C to +70°C |

| Enclosure Type | Industrial-grade casing |

| Power Supply | 24V DC |

| Mounting Type | Rack/DIN rail mounting |

| Dimensions (L×W×H) | 300 x 140 x 45 mm |

| Weight | 0.2 kg |

| Compliance | CE, RoHS, UL |

Product Applications

The DSQC 532B I/O Computer is widely used across numerous industrial sectors where ABB robotic systems are implemented. Common applications include:

-

Automotive Assembly: Controls sensors and actuators in automated welding and assembly lines.

-

Food and Beverage: Facilitates high-speed robotic packaging and palletizing.

-

Pharmaceutical Manufacturing: Ensures sterile, precise operations by interfacing robots with cleanroom-compatible devices.

-

Logistics and Warehousing: Manages conveyor belt sensors and automated picking systems.

-

Metal Fabrication: Interfaces robots with CNC machines and press brakes.

-

Plastic and Rubber Processing: Automates mold handling and extrusion lines.

Product Advantages

-

Seamless Integration: Specifically engineered for ABB robotic ecosystems, ensuring compatibility and ease of setup.

-

Compact Design: Space-saving footprint fits easily into control cabinets.

-

Industrial Durability: Resistant to electrical noise, vibration, and temperature variations.

-

Reliable Communication: Offers consistent and real-time data exchange critical for automation.

-

Flexible I/O Options: Accommodates both digital and analog signals, supporting a wide variety of devices.

-

Future-Proof: Firmware upgradable to adapt to evolving industrial protocols and demands.

Frequently Asked Questions (FAQ)

-

What specific I/O signal types are supported by the DSQC 532B?

The DSQC 532B supports both digital and analog I/O signals, allowing for integration with a wide range of industrial devices such as proximity sensors, actuators, and process transmitters. -

How does the DSQC 532B communicate with the robot controller?

It uses high-speed fieldbus protocols such as Profibus or DeviceNet, and in newer systems, supports Ethernet-based communication for faster data throughput. -

Is there a maximum cable length specification for connecting field devices?

Yes, the maximum cable length depends on the type of signal and protocol used. For example, with Profibus, the recommended maximum is 100–200 meters depending on the baud rate and cable type. -

Does this module support modular expansion?

While the DSQC 532B itself is not modular, it can be connected in a network where additional I/O modules are installed to expand the total I/O capacity of the system. -

What happens if one of the I/O channels fails?

The DSQC 532B is designed to isolate the fault, log it internally, and notify the robot controller through fault codes, allowing the rest of the system to continue operating if configured for redundancy. -

How is electrical noise immunity handled in industrial environments?

The unit features built-in filtering and shielding measures to suppress EMI (Electromagnetic Interference), ensuring stable signal integrity even in electrically noisy environments. -

Can it be mounted horizontally and vertically, or is orientation fixed?

The module supports both horizontal and vertical mounting on DIN rails, allowing flexible installation inside control cabinets with space constraints. -

What is the startup time for the DSQC 532B after power is applied?

The module typically initializes and becomes fully operational within 3 to 5 seconds after power-on, depending on the connected configuration and system load. -

Is configuration handled manually or via ABB software tools?

Configuration is done via ABB’s RobotStudio or similar configuration tools that allow I/O mapping, address assignment, and diagnostic access through an intuitive interface. -

What indicators are present on the DSQC 532B for troubleshooting?

The module includes LED indicators for power, communication status, and I/O channel activity, making it easy to diagnose connection or signal issues without external instruments.

Recommended Related Models (Same Series or Functionality)

| Model Number | Description | Compatibility | Key Feature |

|---|---|---|---|

| DSQC 652 | Profibus Interface Module | IRC5 Controllers | Advanced Profibus communication |

| DSQC 540 | I/O Module for Digital Signals | S4/S4C+ Controllers | High-speed digital processing |

| DSQC 609 | Safety Board | IRC5 and others | Safety-critical applications |

| DSQC 504 | Analog I/O Board | S4C Series | Precise analog input/output |

| DSQC 679 | IRC5 Internal Communication Board | IRC5 | Internal communication management |

| DSQC 223 | DeviceNet I/O Expansion | S4/S4C+ | DeviceNet expansion support |

Popular ABB Modules (Cross-functional, High Demand)

| Model Number | Description | Application Area | Notable Feature |

|---|---|---|---|

| DSQC 100 | Robot Control Unit | General Robotics | Core control logic |

| DSQC 236A | Axis Computer | Motion Control | Multi-axis synchronization |

| DSQC 639 | System Power Supply | Power Distribution | High stability, fault tolerance |

| DSQC 328A | Safety Controller Module | Machine Safety Systems | Redundant architecture |

| DSQC 679 | Communication Interface Board | Robotics & Automation | High-speed data communication |

| DSQC 350 | Resolver Interface Board | Servo Motor Feedback | Accurate positioning |

Excellent PLC

Excellent PLC