| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

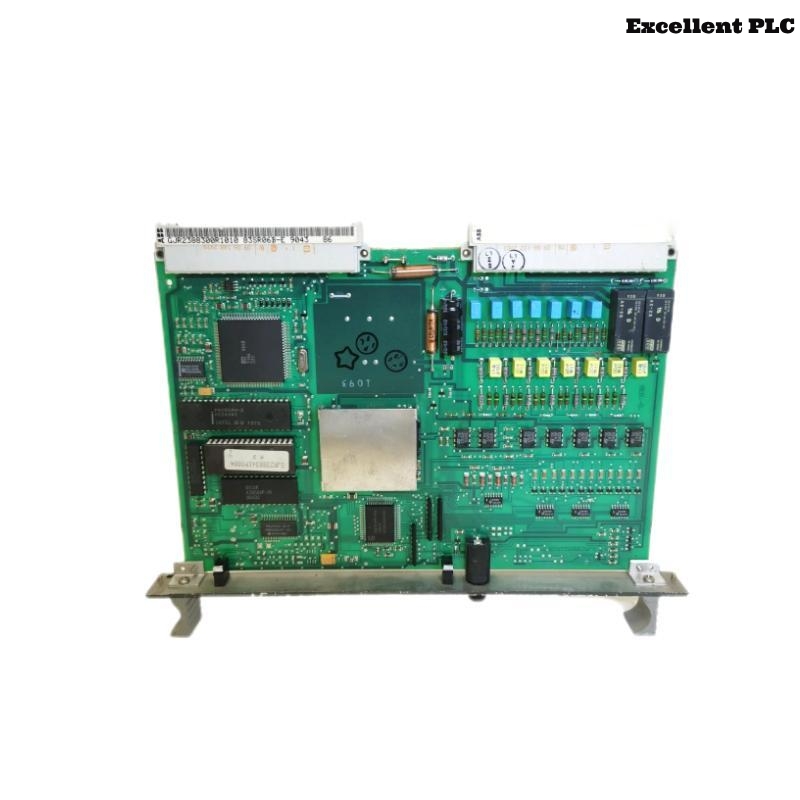

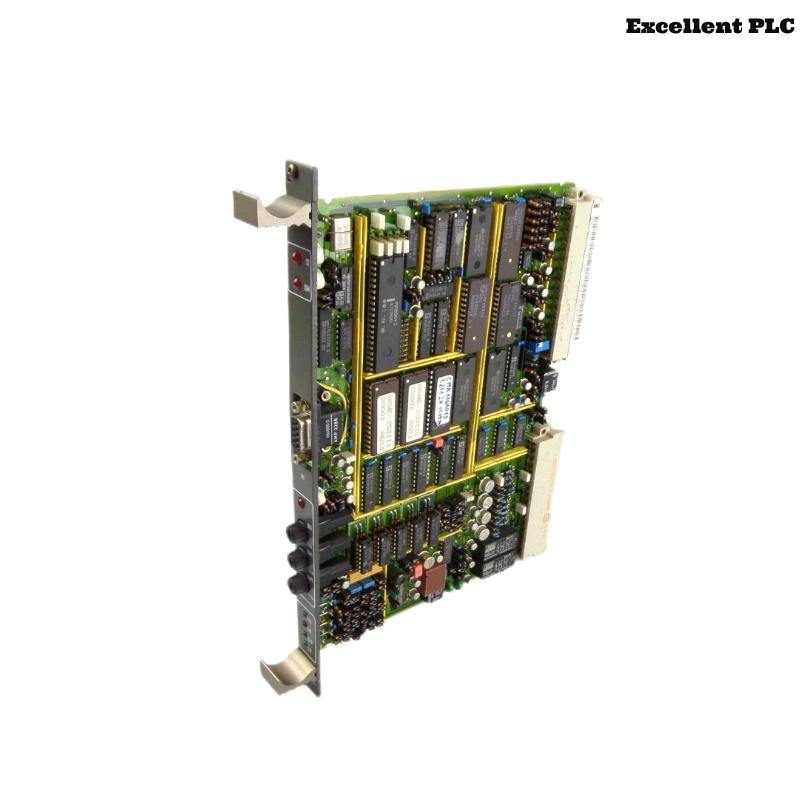

The ABB DI651 (3BHT300026R1) is a robust, high-density digital input module designed for the ABB Advant Controller 410/450 series, widely deployed in complex industrial automation and control systems. Built to collect and process digital signals in critical applications, the DI651 offers a reliable interface between field devices and ABB’s distributed control system (DCS).

Equipped with 64 digital inputs, this module significantly reduces cabinet space and wiring requirements by doubling the channel count in a single housing, making it a practical choice for large-scale installations. The DI651 is engineered with opto-isolated channels, ensuring high immunity against electromagnetic interference and electrical surges, while offering accurate, real-time signal detection.

Its compact design, excellent electrical protection, and seamless integration with legacy and current ABB control architectures make it a staple in industrial settings such as energy generation, refining, chemical manufacturing, metals, and utilities.

Technical Specifications

| Parameter | Specification |

|---|---|

| Product Name | DI651 Digital Input Module |

| Part Number | 3BHT300026R1 |

| Number of Channels | 64 digital inputs |

| Nominal Input Voltage | 24 V DC |

| Input Voltage Range | 18 – 30 V DC |

| Input Current | Approx. 6 mA per channel at 24 V DC |

| Input Signal Type | Binary (Discrete), opto-isolated |

| Input Isolation | Optical isolation between input and logic circuits |

| Channel Grouping | Typically 16 channels per group |

| Response Time | < 10 ms |

| Field Wiring | Terminal base unit (via backplane and connectors) |

| Diagnostics | Channel group diagnostics and fault reporting |

| LED Indicators | Status LEDs per input group |

| System Interface | Backplane bus (Advant Controller system) |

| Power Supply | Supplied via system backplane |

| Operating Temperature | 0°C to +60°C |

| Storage Temperature | -40°C to +70°C |

| Humidity | 5% to 95% non-condensing |

| Protection Class | IP20 |

| Certifications | CE, UL, CSA, RoHS |

| Mounting Type | DIN rail or rack-based mounting |

| Dimensions (W x H x D) | 252 x 273 x 40 mm |

| Weight | 1.23 kg |

| System Compatibility | Advant Controller 410/450, Symphony DCI, and compatible systems |

Applications

-

Power Plants (Fossil, Nuclear, Renewable)

Monitors critical equipment states like valve positions, circuit breakers, and safety interlocks. -

Oil & Gas Facilities

Handles digital feedback from process instruments, alarm contacts, emergency shutdown systems (ESD), and valve limit switches. -

Chemical Processing Units

Interfaces with digital signals from safety relays, interlocks, and sequencing controls in batch or continuous processes. -

Pulp & Paper Mills

Collects input from conveyor switches, motor starters, and limit sensors throughout production lines. -

Mining and Metallurgy Plants

Used for heavy-duty contact inputs in rugged environments, including crushers, grinders, and safety gate monitoring. -

Industrial Automation Systems

Supports high-speed input scanning for real-time control of machinery, robotics, and conveyance systems. -

Water Treatment and Wastewater Facilities

Reads pump and valve statuses, overflow conditions, and contact closure signals for control room feedback.

Key Advantages

-

Ultra-High Channel Density

64 digital inputs in a compact footprint significantly lower rack space and wiring complexity. -

Proven in Mission-Critical Systems

Trusted in global industries with long service life and consistent field reliability. -

Comprehensive Diagnostics

Built-in group diagnostics simplify troubleshooting and preventive maintenance. -

Flexible System Integration

Works seamlessly with ABB’s Advant and Symphony platforms—ideal for both upgrades and greenfield installations. -

Reduced Downtime

Field-replaceable without disrupting system-wide operations; supports hot-swapping in some configurations. -

Enhanced Electrical Protection

Opto-isolation and protective circuitry prevent damage from voltage surges and transients. -

Lifecycle Support & Spare Availability

ABB offers extended support programs and long-term availability of spares and replacements.

Latest Industry News Headlines

-

ABB Extends Service Lifecycle for DI651 in Power and Water Applications

-

DI651 Survives Harsh Offshore Conditions in North Sea Platform

-

ABB DI651 Cuts Space and Cabling by 50% in Refinery Revamp Project

-

ABB Releases Updated Configuration Tools for DI600 Series Modules

-

DI651 Used in Smart Grid Modernization Project in Europe

-

ABB Announces Diagnostic Enhancements for Digital Input Modules

-

Control System Migration: DI651 Helps Bridge Legacy Advant and Symphony Plus

-

ABB DI Modules Hit 25-Year Mark in Continuous Operation at Steel Plant

-

ABB Provides Retrofit Kits for DI610/620/651 Digital Inputs

-

ABB Strengthens Cybersecurity Firmware in DI Series

Frequently Asked Questions (FAQ)

-

What is the maximum number of DI651 modules that can be installed in one controller rack?

It depends on system load and power budget; typically 4–6 per rack with spacing considerations. -

Does DI651 support individual channel diagnostics?

No, diagnostics are grouped. Individual channel diagnostics are not available on this model. -

Is hot-swapping possible with the DI651 module?

Only in systems configured for redundancy and hot-swap support. Most installations require a safe stop. -

What kind of field signals can the module detect?

Any dry contact or active 24 VDC signal from limit switches, relays, sensors, etc. -

How is the wiring done for 64 channels?

Wiring is managed via terminal base units, often segmented into groups for cable organization. -

Is the DI651 supported in ABB’s current configuration tools?

Yes, supported via legacy Advant tools and partially in Symphony Plus engineering environment. -

Can it be used with third-party PLCs?

Not directly. DI651 is tailored for ABB’s proprietary bus and system architecture. -

How is LED indication implemented?

Status LEDs are available per input group, not per channel. -

What happens in case of a module fault?

The system will trigger an alarm; group diagnostics and hot standby modules (if configured) handle failover. -

Is there any compatibility between DI651 and S800 I/O systems?

No. DI651 is part of the Advant DCS line, while S800 is a separate modular I/O system.

Related Models (Same Series or Function)

| Model | Description | Channels | Voltage | System Compatibility |

|---|---|---|---|---|

| DI610 3BHT300004R1 | Digital Input Module | 16 DI | 24 V DC | Advant Controller 410/450 |

| DI620 3BHT300002R1 | Medium-Density Digital Input Module | 16 DI | 24 V DC | Advant Controller |

| DI621 3BHT300012R1 | High-Density Digital Input Module | 32 DI | 24 V DC | Advant Controller |

| DO610 3BHT300006R1 | Digital Output Module | 16 DO | 24 V DC | Advant Controller |

| AI610 3BHT300000R1 | Analog Input Module | 8 AI | 0-20 mA | Advant Controller |

| AO610 3BHT300003R1 | Analog Output Module | 8 AO | 0-20 mA | Advant Controller |

| DI810 3BSE008508R1 | S800 I/O Digital Input Module | 16 DI | 24 V DC | 800xA / Freelance / S800 I/O |

| TU845 3BSE021447R1 | Terminal Unit for DI Modules | 16 DI | 24 V DC | Advant Controller / S800 I/O |

Popular ABB Automation Modules

| Model | Description | Type | Typical Use |

|---|---|---|---|

| PM864AK01 | Compact High-Performance CPU Module | CPU Controller | 800xA DCS |

| CI860 3BSE032444R1 | MB300 Interface for Harmony Migration | Communication Module | Legacy System Integration |

| DO820 3BSE008512R1 | Digital Output Module | I/O Module | Discrete Control |

| AI810 3BSE008516R1 | Analog Input Module | I/O Module | Sensor Interface |

| CP600 Series HMI | Operator Interface Panel | HMI | Process Monitoring |

| TU849 3BSE042560R1 | Base Unit for I/O Modules | Terminal Block | Mounting and Wiring Interface |

| PM865K01 | Redundant CPU Unit | Controller CPU | High Availability Control Systems |

| CI854AK01 | PROFIBUS-DP Communication Interface | Fieldbus Module | Remote I/O Communication |

Excellent PLC

Excellent PLC