| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

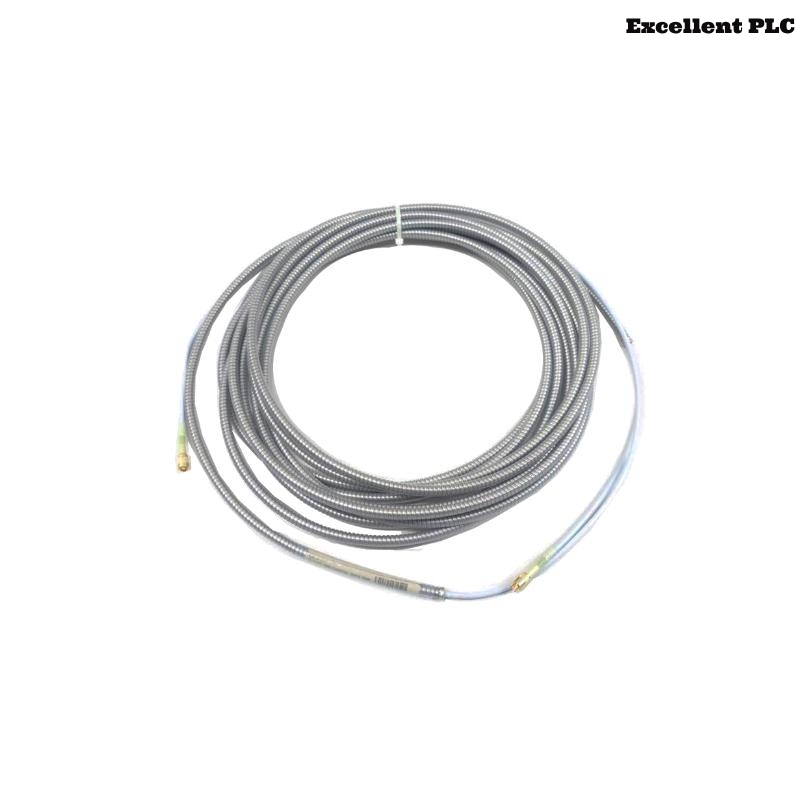

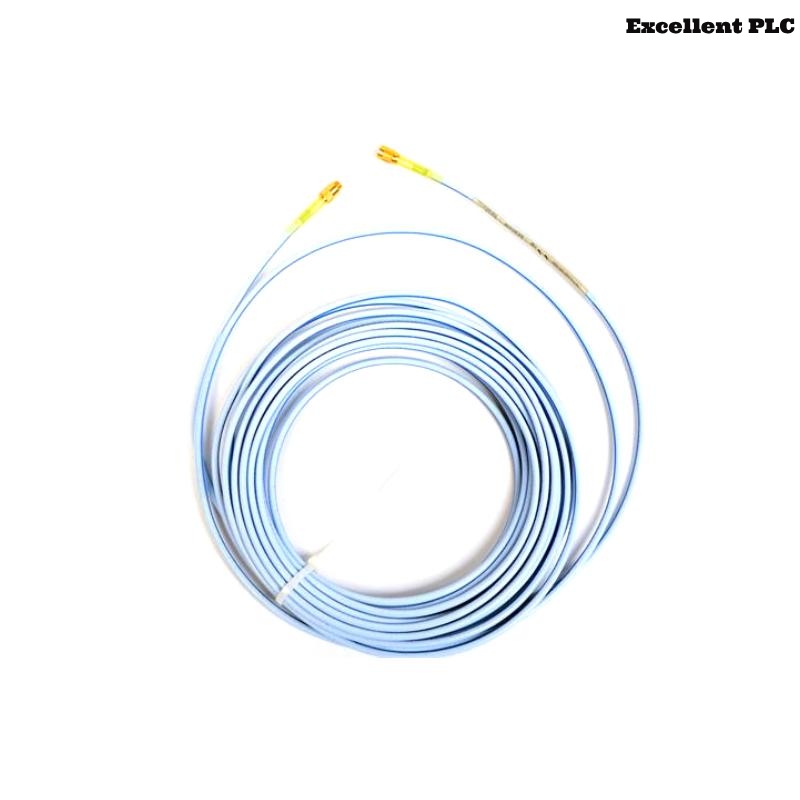

The Bently Nevada 21504-000-012-05-02 is a precision-engineered proximity probe designed for use in the 7200 series condition monitoring systems. It supports both 5 mm and 8 mm configurations, making it highly adaptable for diverse machinery monitoring applications. As part of a trusted product family known for reliable non-contact vibration and position measurement, this standard mount probe helps maintain operational safety and performance across critical rotating assets.

Utilized extensively in the oil & gas, power generation, and process industries, this model is well-suited for shaft displacement, radial vibration, and thrust position monitoring. The probe is designed for compatibility with matching extension cables and Proximitor sensors, forming a complete, factory-calibrated measurement system.

Technical Specifications

| Parameter | Specification |

|---|---|

| Product Model | 21504-000-012-05-02 |

| Series | Bently Nevada 7200 Series |

| Probe Tip Diameter | Dual support for 5 mm and 8 mm configurations |

| Thread Size | 3/8-24 UNF |

| Total Length | 3 m |

| Mounting Style | Standard cylindrical mount |

| Sensing Technology | Eddy current, non-contact measurement |

| Material Compatibility | Calibrated for ferromagnetic materials (typically AISI 4140 steel) |

| Connector Type | Miniature coaxial connector (MIL-style) |

| Operating Temperature | -35°C to +120°C |

| Frequency Range | 0 to 10 kHz |

| Sensitivity | 200 mV/mil (7.87 mV/μm) |

| Linearity Range | ±0.25 mils across an 80-mil range |

| Ingress Protection | IP65 (when properly installed and sealed) |

| Certifications | CE, RoHS compliant |

| Typical System Compatibility | Bently Nevada 7200 Series Proximitor and matching extension cables |

| Weight | 0.75 kg |

Product Applications

The 21504-000-012-05-02 is a highly versatile probe model suitable for various industrial machinery, including:

-

Gas and Steam Turbines

Monitoring shaft displacement, axial thrust, and vibration for early fault detection. -

Compressors (Axial, Centrifugal, Reciprocating)

Real-time monitoring of mechanical wear, rotor positioning, and misalignment. -

Industrial Motors & Generators

Shaft vibration and bearing condition monitoring to ensure safe operation. -

Gearboxes and Transmission Systems

Detection of gear misalignment and axial shifting under load. -

Pumps (Centrifugal and Positive Displacement)

Ideal for monitoring cavitation effects and detecting early-stage bearing damage. -

Fans, Blowers, and Other High-Speed Equipment

Ensures vibration within tolerances to prevent premature equipment failure.

Product Advantages

-

Flexible Tip Configuration (5 mm and 8 mm)

Compatible with both tight spaces and standard applications, providing deployment flexibility. -

Accurate Eddy Current-Based Measurement

Offers reliable shaft vibration and displacement detection under dynamic load conditions. -

Robust Mechanical Design

Engineered for rugged environments with vibration, oil mist, and temperature fluctuations. -

Seamless System Integration

Matches precisely with Bently Nevada Proximitor sensors and extension cables. -

Low Drift and High Linearity

Maintains signal integrity and accuracy even in long-term industrial operation. -

Field-Proven Durability

Extensively deployed in demanding industries; trusted in mission-critical equipment. -

Fast Response Time

Real-time measurements suitable for high-speed rotating machinery protection systems.

Frequently Asked Questions (FAQ)

-

Can this probe be used with any proximity monitoring system?

No. It is designed specifically for use with Bently Nevada 7200 Series systems for accurate calibration. -

What makes it compatible with both 5 mm and 8 mm configurations?

The probe design allows the use of tips in both diameters, enabling fit in varied installation conditions. -

What type of materials can it measure accurately?

It is factory-calibrated for ferromagnetic materials such as AISI 4140 steel. -

Is this probe suitable for high-vibration applications?

Yes. It can tolerate peak vibrations up to 20 g, making it ideal for turbines and compressors. -

Can the probe cable length be modified after purchase?

No. Modifying cable length alters system calibration and is not recommended. -

Is recalibration necessary during equipment servicing?

Recalibration is advised during major overhauls or every 3–5 years. -

What is the expected lifespan of the probe?

With proper installation, it can operate effectively for over 5–10 years without degradation. -

How is the probe sealed against contaminants?

It comes with sealed connectors and an IP65-rated body to withstand industrial environments. -

Does it support hazardous area certification?

This model does not come with ATEX/IECEx certification. Check explosion-proof variants if needed. -

Is there a temperature limitation for continuous use?

Yes, it should be used within the -35°C to +120°C operating range for optimal accuracy.

Related Models – Same Series or Function

| Model Number | Description | Cable Length | Tip Diameter | Application |

|---|---|---|---|---|

| 21504-000-005-10-02 | Standard 5 mm probe | 10 ft | 5 mm | Compact sensor mounting |

| 21504-000-008-10-02 | Standard 8 mm probe | 10 ft | 8 mm | General purpose machinery monitoring |

| 330101-00-08-10-02 | 3300 XL 8 mm probe | 10 ft | 8 mm | Next-gen monitoring compatibility |

| 330103-00-05-10-02 | 3300 XL 5 mm probe | 10 ft | 5 mm | Used in space-constrained areas |

| 330104-00-05-10-02 | 3300 XL Proximitor system probe | 10 ft | 5 mm | High-sensitivity applications |

| 7200-14-10-01 | 7200 Proximitor Sensor | N/A | N/A | Matched with 21504 series probes |

Popular Models from Bently Nevada

| Model Number | Description | Category | Function |

|---|---|---|---|

| 3500/22M | Transient Data Interface Module | Rack Module | Communication interface for monitoring |

| 3500/42M | Proximitor Monitor | Rack Module | Interfaces proximity sensors |

| 330500 | High-Temperature Accelerometer | Vibration Sensor | For hot, heavy-duty machinery |

| 330180-91-00 | Velomitor Velocity Sensor | Casing Sensor | Measures velocity of machine casing |

| 3500/05 | 19″ Rack for 3500 Series Modules | Monitoring Hardware | Structural housing for system modules |

| 990-05-70-01-00 | Thrust Position Measurement Kit | Position Monitoring Kit | Axial displacement measurement |

Excellent PLC

Excellent PLC