| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

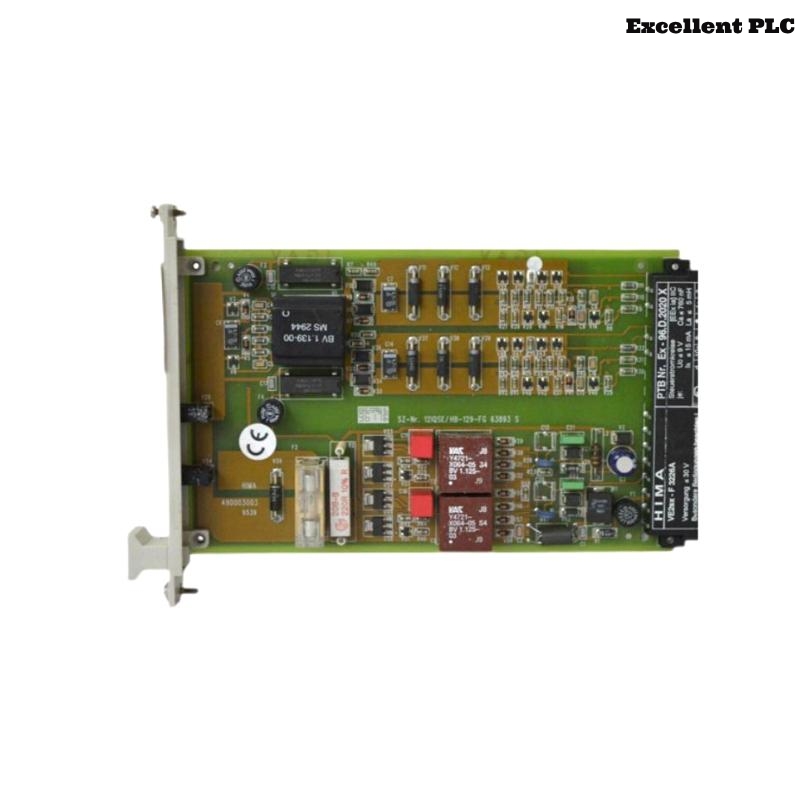

The HIMA F8641 CPU Module is an advanced, highly reliable central processing unit designed for safety-related applications in industrial automation systems. Part of the HIMA HIMax series, the F8641 is built to handle complex safety tasks in critical processes where reliability, real-time processing, and fault tolerance are paramount. The module serves as the core of the safety system, processing safety logic and managing communication with I/O modules, remote stations, and higher-level systems.

The F8641 CPU is equipped with robust features, including integrated diagnostics, redundancy support, and the ability to handle complex safety standards such as SIL 3, making it ideal for applications where system downtime is not acceptable. Designed to meet stringent industry requirements, this module ensures the continuous availability of safety systems, even in the face of faults, thus protecting both personnel and equipment in hazardous environments.

The HIMA F8641 is also known for its ease of integration with other safety systems and components, offering flexibility in installation and configuration. Its performance and reliability make it suitable for industries like chemical plants, power generation, oil and gas, and pharmaceuticals, where safety is critical to operational success.

Product Specifications

| Specification | Details |

| Model | HIMA F8641 CPU Module |

| CPU Type | Dual-Core, Real-Time Processing |

| Operating System | Custom Real-Time Operating System |

| Safety Certification | SIL 3 (Safety Integrity Level) |

| Communication Protocol | Ethernet, MODBUS, PROFINET, PROFIBUS, CAN |

| Processor Speed | 1.2 GHz |

| Memory (RAM) | 1 GB |

| Memory (Flash) | 8 GB |

| Dimensions (L x W x H) | 160 x 100 x 30 mm |

| Weight | 0.8 kg |

| Power Supply | 24 V DC (±20%) |

| Temperature Range | -20°C to +60°C |

| Mounting | DIN Rail Mounting |

| Redundancy | Hot Standby Redundancy |

| Protection Class | IP20 (dust-tight, no protection against water) |

| Environment | Suitable for industrial environments |

Product Applications

The HIMA F8641 CPU Module is designed for use in critical safety applications that require high reliability and real-time processing. Some of its key applications include:

-

Process Control: In industries such as chemical manufacturing and oil refining, the F8641 is used to control safety systems and monitor hazardous processes.

-

Emergency Shutdown Systems (ESD): The module is a key component in emergency shutdown systems, ensuring that in the event of an emergency, critical processes are safely halted.

-

Fire and Gas Detection: It is used to process inputs from fire and gas detectors to take appropriate actions, ensuring that safety measures are implemented swiftly in dangerous situations.

-

Shutdown Logic Systems: For plants where shutdown procedures must be executed automatically to protect both personnel and equipment, the F8641 provides reliable control.

-

Critical Infrastructure Protection: Used in power plants and substations, where the F8641 module ensures that critical infrastructure is always operating safely and reliably.

-

Safety Instrumented Systems (SIS): The F8641 forms the heart of many SISs, providing safe, real-time processing of input from various sensors and actuators.

-

High-Risk Industrial Plants: Its SIL 3 certification makes it ideal for high-risk environments such as refineries, offshore oil rigs, and nuclear plants, where failure is not an option.

-

Automated Test Systems: The F8641 is also used in automated testing setups, where precise and fast control of various processes is required to maintain test integrity.

Product Advantages

-

High Safety Integrity: With SIL 3 certification, the F8641 meets the highest standards of safety, making it ideal for applications in hazardous industries where risk reduction is paramount.

-

Real-Time Processing: The CPU features fast, deterministic real-time processing capabilities, enabling quick response times critical to safety applications.

-

Redundancy Support: The F8641 supports hot standby redundancy, ensuring that the system continues to function without interruption in case of hardware failure.

-

Flexible Communication Options: The module supports a wide range of communication protocols, including Ethernet, MODBUS, PROFINET, PROFIBUS, and CAN, making it adaptable to various system requirements.

-

Diagnostics and Monitoring: Integrated diagnostics help monitor the health of the system in real-time, providing early warnings of potential failures and reducing the risk of unplanned downtime.

-

Compact Design: The compact dimensions of the F8641 make it easy to integrate into existing control cabinets and industrial racks.

-

Low Power Consumption: The module operates on a 24 V DC power supply and consumes minimal power, making it energy efficient.

-

Easy Integration: The F8641 is designed for easy integration with other safety systems and components, enabling seamless communication and control in complex safety systems.

Latest News Headlines

-

“HIMA’s F8641 CPU Module Elevates Safety Standards in Hazardous Industries.”

-

“Revolutionizing Emergency Shutdown Systems: The Role of the HIMA F8641.”

-

“Ensuring Safe Operations in Oil and Gas with HIMA F8641 CPU Module.”

-

“How HIMA’s F8641 CPU is Shaping the Future of Process Control Systems.”

-

“HIMA Introduces New Real-Time Processing Capabilities with F8641 CPU.”

-

“F8641: The Next Generation Safety CPU for Critical Infrastructure Protection.”

-

“HIMA’s F8641 Offers Seamless Integration with Modern Safety Systems.”

-

“Advanced Diagnostics and Redundancy in the F8641 Ensure Maximum Uptime.”

-

“HIMA CPU Module F8641: The Key to Managing Risk in High-Risk Environments.”

-

“Improving Plant Safety with the HIMA F8641 CPU: A Success Story.”

Frequently Asked Questions (FAQ)

-

What is the safety certification of the HIMA F8641 CPU?

-

The F8641 CPU has a SIL 3 (Safety Integrity Level) certification, making it suitable for high-risk, safety-critical applications.

-

-

What is the power supply requirement for the F8641?

-

The F8641 requires a 24 V DC power supply, with a tolerance of ±20%.

-

-

What communication protocols does the F8641 support?

-

The module supports Ethernet, MODBUS, PROFINET, PROFIBUS, and CAN protocols for seamless communication.

-

-

What is the temperature range in which the F8641 can operate?

-

The F8641 can operate in a temperature range of -20°C to +60°C.

-

-

Does the F8641 support redundancy?

-

Yes, the F8641 supports hot standby redundancy, ensuring continuous operation in case of hardware failure.

-

-

What are the dimensions of the F8641 CPU module?

-

The module’s dimensions are 160 mm x 100 mm x 30 mm.

-

-

What industries is the F8641 suitable for?

-

The F8641 is designed for use in industries such as chemical processing, oil and gas, power generation, and other high-risk environments.

-

-

How is the F8641 CPU mounted?

-

The F8641 is mounted on a DIN rail, making installation easy in industrial control cabinets.

-

-

Can the F8641 be used in remote locations?

-

Yes, the F8641 supports remote communication and can be used in distributed safety systems across large plants or facilities.

-

-

What are the main benefits of using the F8641 CPU?

-

The F8641 offers high safety integrity, real-time processing, redundancy support, and easy integration, making it ideal for critical safety applications.

-

Recommended Related Models

| Model | Safety Certification | Communication Protocol | Dimensions (L x W x H) | Weight |

| HIMA F8651 | SIL 3 | Ethernet, MODBUS | 180 mm x 120 mm x 40 mm | 0.85 kg |

| HIMA F8601 | SIL 2 | PROFIBUS, CAN | 170 mm x 110 mm x 35 mm | 0.75 kg |

| HIMA F8611 | SIL 3 | PROFINET, Ethernet | 175 mm x 100 mm x 40 mm | 0.78 kg |

| HIMA F8640 | SIL 3 | MODBUS, PROFIBUS | 160 mm x 100 mm x 30 mm | 0.80 kg |

| HIMA F8621 | SIL 3 | Ethernet, CAN | 165 mm x 105 mm x 38 mm | 0.76 kg |

| HIMA F8600 | SIL 2 | PROFINET, CAN | 170 mm x 110 mm x 40 mm | 0.79 kg |

| HIMA F8690 | SIL 3 | Ethernet, PROFIBUS | 180 mm x 115 mm x 45 mm | 0.82 kg |

| HIMA F8661 | SIL 3 | Ethernet, MODBUS | 160 mm x 100 mm x 35 mm | 0.77 kg |

Recommended Popular Models from HIMA

| Model | Safety Certification | Communication Protocol | Dimensions (L x W x H) | Weight |

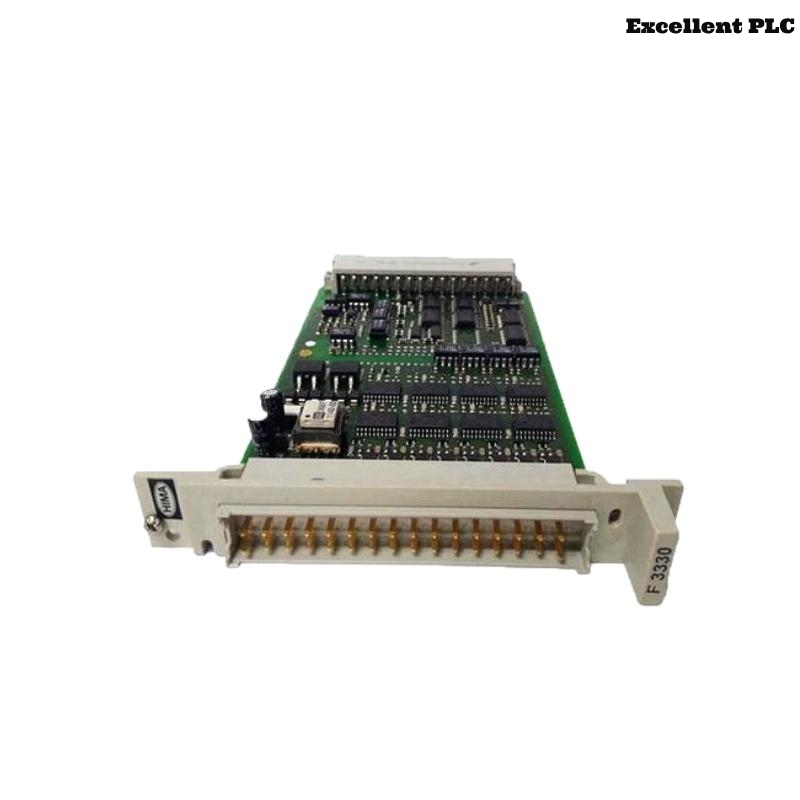

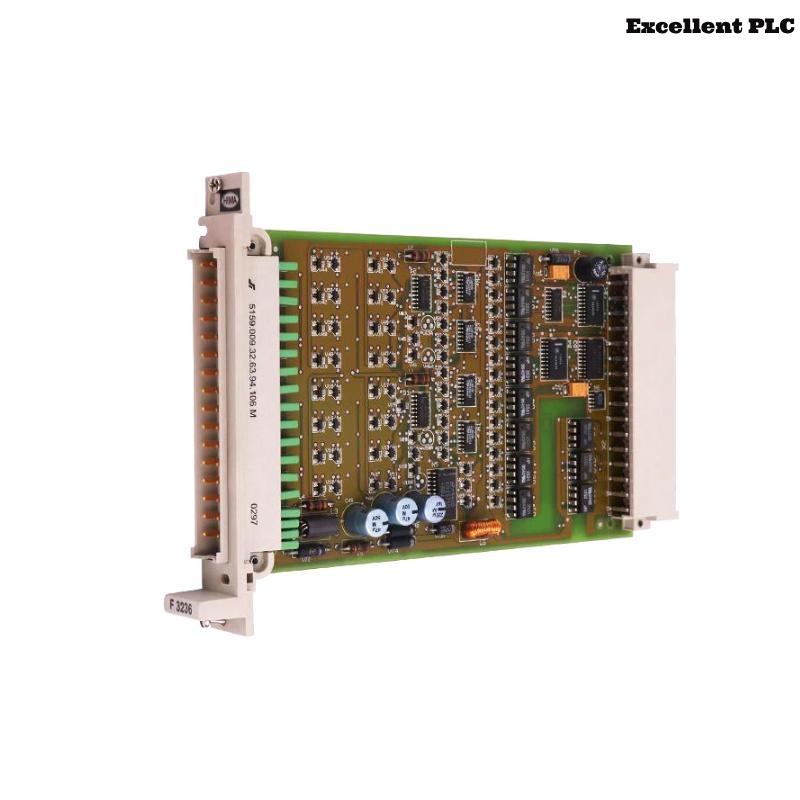

| HIMA F3330 | SIL 3 | MODBUS, Ethernet | 190 mm x 120 mm x 45 mm | 0.95 kg |

| HIMA F2130 | SIL 3 | PROFIBUS, CAN | 175 mm x 100 mm x 40 mm | 0.88 kg |

| HIMA F2110 | SIL 3 | Ethernet, CAN | 180 mm x 110 mm x 38 mm | 0.92 kg |

| HIMA F2210 | SIL 3 | Ethernet, MODBUS | 165 mm x 105 mm x 35 mm | 0.85 kg |

| HIMA F2111 | SIL 2 | CAN, MODBUS | 160 mm x 100 mm x 30 mm | 0.80 kg |

| HIMA F2230 | SIL 3 | PROFIBUS, Ethernet | 175 mm x 110 mm x 40 mm | 0.90 kg |

| HIMA F2320 | SIL 3 | Ethernet, PROFINET | 180 mm x 115 mm x 45 mm | 0.94 kg |

| HIMA F2510 | SIL 3 | Ethernet, MODBUS | 160 mm x 100 mm x 40 mm | 0.88 kg |

Excellent PLC

Excellent PLC