| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview:

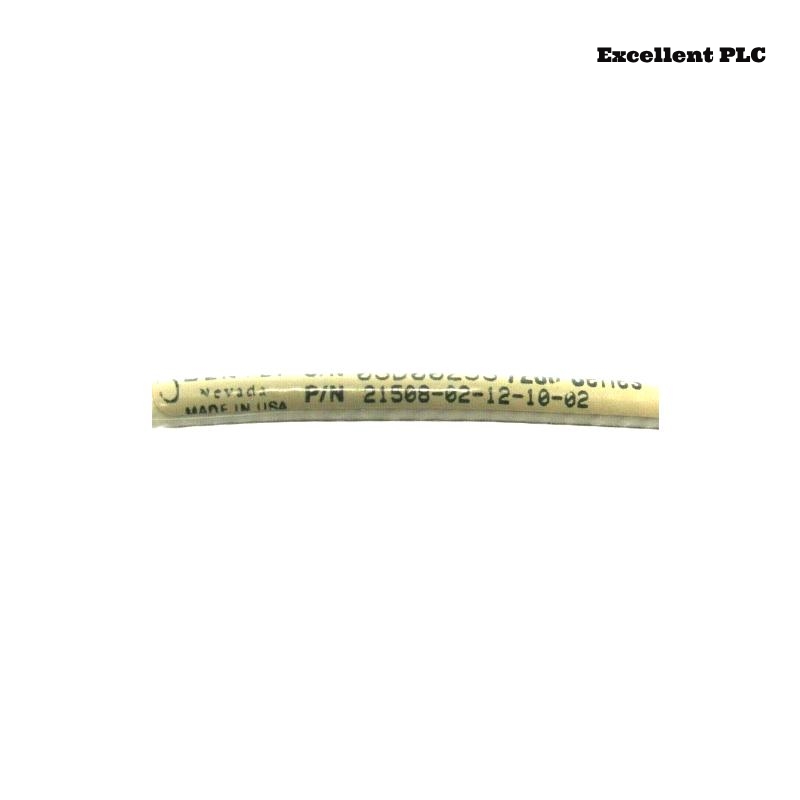

The Bently Nevada 21508-02-12-10-02 8 mm Reverse Mount Probe is a high-precision, durable proximity probe designed for use in critical vibration monitoring systems. The 21508 series probes are primarily used to measure the displacement of rotating machinery components such as shafts and bearings. This probe is part of Bently Nevada’s advanced monitoring systems, which provide real-time data for predictive maintenance, fault detection, and performance optimization. The reverse mount design of this probe allows for installation in limited spaces while still providing reliable and accurate measurements of vibration and displacement.

The 8 mm diameter probe is ideal for applications that require precision and reliability in environments where space constraints are a consideration. The probe’s reverse mounting feature allows it to be mounted from the rear, making it a perfect choice for applications where space is limited or when other mounting options are impractical.

Product Specifications:

| Specification | Details |

|---|---|

| Model Number | 21508-02-12-10-02 |

| Probe Type | Reverse Mount Proximity Probe |

| Probe Diameter | 8 mm |

| Mounting Type | Reverse Mount |

| Material | Stainless Steel |

| Temperature Range | -40°C to +120°C |

| Vibration Frequency Range | 0 to 1000 Hz |

| Maximum Pressure | 1500 psi |

| Cable Length | 1 mm |

| Weight | 0.59 kg |

| IP Protection | IP67 |

| Maximum Vibration Displacement | 0.25 mm |

| Operating Environment | Harsh industrial environments (wet, high-temp, etc.) |

Applications:

The Bently Nevada 21508-02-12-10-02 8 mm Reverse Mount Probe is commonly used in various industrial sectors where precise vibration and displacement monitoring of rotating machinery is crucial. Typical applications include:

-

Power Generation: In turbines, motors, and generators to detect shaft displacement and misalignment.

-

Oil and Gas: Used in pumps, compressors, and turbines to monitor equipment health and prevent failure.

-

Chemical Manufacturing: Monitors high-speed rotating machinery like mixers, pumps, and reactors.

-

Pulp and Paper Industry: Ensures accurate measurement of critical machines such as presses and paper mills.

-

Mining: Installed in crushers, mills, and conveyors to detect early signs of mechanical failure.

-

Aerospace and Defense: Monitors machinery in aircraft engines, ensuring accurate performance during operations.

-

HVAC Systems: Measures vibration of large ventilation and air conditioning units, preventing mechanical breakdowns.

Advantages:

-

Compact and Efficient Design: The reverse mount design of the 21508-02-12-10-02 allows for installation in tight spaces, saving valuable room without compromising performance.

-

Durable Construction: Made of stainless steel, the probe is resistant to corrosion and wear, providing reliable performance even in harsh environments.

-

Accurate Vibration Measurement: Provides precise measurement of shaft displacement and vibration, improving the accuracy of fault detection and maintenance scheduling.

-

Wide Temperature and Pressure Range: With a broad operating temperature range of -40°C to +120°C and the ability to withstand up to 1500 psi, it is suitable for extreme environments.

-

High IP Rating: The IP67 rating ensures the probe is protected against dust and can be submerged in water up to 1 meter, offering superior durability in industrial settings.

-

Enhanced Reliability: Helps in minimizing machine downtime and extending the lifespan of expensive equipment by enabling predictive maintenance practices.

-

Ease of Installation: The reverse mounting feature allows for easier installation in tight spaces, particularly in areas where front mounting is not feasible.

Recent News Headlines:

-

“Bently Nevada Launches Compact Reverse Mount Proximity Probe for Harsh Industrial Environments”

-

“Innovative Vibration Monitoring with Bently Nevada’s 21508 Reverse Mount Proximity Probe”

-

“Bently Nevada’s 8 mm Proximity Probe Enhances Condition Monitoring Across Multiple Industries”

-

“Advanced Vibration Monitoring: Bently Nevada’s Reverse Mount Probe Optimizes Performance in Power Plants”

-

“New Bently Nevada Proximity Probe Offers Unmatched Durability for Oil and Gas Operations”

-

“Revolutionizing Vibration Monitoring in Chemical Manufacturing with Bently Nevada’s 21508 Probe”

-

“Bently Nevada’s Latest 8 mm Reverse Mount Probe Improves Vibration Data Accuracy in Mining”

-

“Bently Nevada 21508-02-12-10-02: A Breakthrough in Aerospace Vibration Monitoring Technology”

Frequently Asked Questions (FAQs)

-

What is the primary function of the Bently Nevada 21508-02-12-10-02 8 mm Reverse Mount Probe?

The probe is used to measure the vibration and displacement of rotating machinery components, particularly in constrained environments where traditional front-mount probes are impractical.

-

How does the reverse mounting feature benefit the installation process?

The reverse mounting design allows the probe to be installed from the rear, making it ideal for tight spaces and areas where front mounting is not feasible.

-

What is the maximum operating temperature for the 21508-02-12-10-02 probe?

The probe can operate in temperatures ranging from -40°C to +120°C, making it suitable for a wide range of industrial environments.

-

What types of machines are suitable for this probe?

The probe is typically used in high-speed rotating machinery such as turbines, motors, pumps, compressors, and other critical industrial equipment.

-

What is the protection rating of the Bently Nevada 21508-02-12-10-02?

The probe has an IP67 protection rating, meaning it is dustproof and can withstand immersion in water up to 1 meter.

-

How does the 21508-02-12-10-02 improve machine reliability?

By providing real-time vibration and displacement data, the probe helps in early fault detection, allowing for predictive maintenance and preventing costly downtime.

-

What is the weight of the Bently Nevada 21508-02-12-10-02?

The probe weighs 0.59 kg, making it lightweight and easy to handle during installation and maintenance.

-

Can this probe be used in hazardous environments?

Yes, the probe is designed to withstand harsh industrial environments, including those with high pressure and extreme temperatures.

-

How accurate is the vibration measurement with this probe?

The probe provides highly accurate displacement and vibration readings, with a measurement range that helps detect even slight misalignments or imbalances in rotating machinery.

-

What are the key advantages of using this probe in vibration monitoring systems?

The key benefits include enhanced accuracy, easy installation, high durability, and suitability for installation in limited space, making it an ideal choice for many industrial applications.

Recommended Models

| Model Number | Description | Key Feature |

|---|---|---|

| Bently Nevada 21508-02-12-10-03 | 8 mm Reverse Mount Probe | Enhanced pressure rating |

| Bently Nevada 21508-02-12-10-04 | 8 mm Reverse Mount Probe | Ideal for high-temperature applications |

| Bently Nevada 21509-02-12-10-02 | 8 mm Probe for Smaller Machinery | Suitable for compact machines |

| Bently Nevada 21510-02-12-10-02 | 10 mm Reverse Mount Probe | Larger probe diameter for larger machinery |

| Bently Nevada 21508-02-12-10-05 | 8 mm Reverse Mount Probe with Extended Range | Extended displacement measurement capabilities |

| Bently Nevada 21508-02-12-10-06 | 8 mm Probe with Low-Noise Performance | Optimized for noise-sensitive environments |

| Bently Nevada 21508-02-12-10-07 | Reverse Mount Probe for High-Speed Rotating Equipment | High-speed machinery compatibility |

| Bently Nevada 21508-02-12-10-08 | 8 mm Probe with Corrosion-Resistant Coating | Enhanced protection in corrosive environments |

Popular Bently Nevada Models

| Model Number | Description | Key Feature |

|---|---|---|

| Bently Nevada 330130-040-00 | Vibration Transducer | Precision vibration measurement |

| Bently Nevada 3300 XL | Proximity Transducer | High-resolution displacement sensing |

| Bently Nevada 3500/42M | Dynamic Pressure Module | Pressure measurement for dynamic systems |

| Bently Nevada 330100-065-05 | Vibration Monitoring System | Multi-channel vibration monitoring |

| Bently Nevada 3500/22M | Vibration Monitoring Module | Comprehensive vibration data collection |

| Bently Nevada 3300 | Proximity Probe | High-accuracy proximity sensing |

| Bently Nevada 3500/53 | System Monitoring Module | Multi-channel monitoring for large machines |

| Bently Nevada 330100-065-02 | Proximity Probe | General-purpose proximity sensing |

Excellent PLC

Excellent PLC