| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

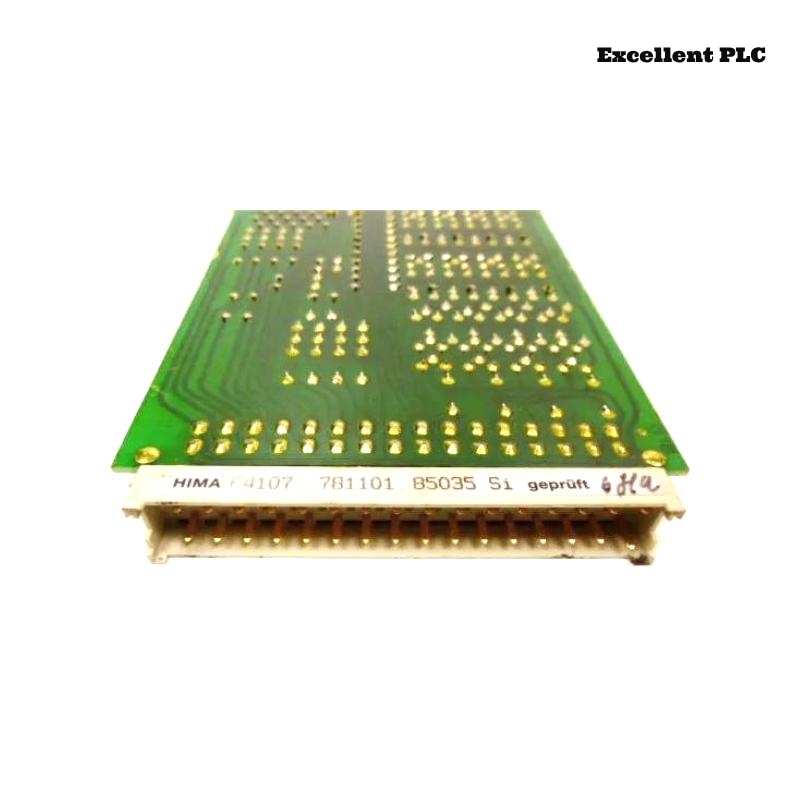

The HIMA F4107 Safety-Related and Door Module is an advanced industrial control module engineered to enhance operational efficiency and safety within industrial automation systems. Designed for seamless integration with various control systems, the F4107 provides reliable performance even in harsh industrial environments. Its primary function includes managing safety protocols and door control mechanisms, ensuring both equipment and personnel are safeguarded during operations.

Technical Specifications

| Specification | Details |

|---|---|

| Model Number | F4107 |

| Type | Safety-Related and Door Module |

| Input Voltage | 24V DC |

| Current Consumption | 500 mA |

| Processing Speed | 100 kHz |

| Input Channels | 16 digital inputs |

| Output Channels | 8 digital outputs |

| Communication Protocol | PROFIBUS DP |

| Safety Certification | SIL 3 certified |

| Operating Temperature | -20°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Dimensions (L x W x H) | 120 x 80 x 40 mm |

| Weight | 0.25 kg |

| Housing Material | High-durability plastic |

| Mounting Type | DIN rail mountable |

| Protection Class | IP20 |

Applications

The HIMA F4107 module is versatile and suitable for a wide range of industrial applications, particularly in environments requiring stringent safety measures and door control mechanisms. Key applications include:

-

Industrial Automation: Ensuring safe operation of machinery by monitoring and controlling access points and emergency stop functions.

-

Manufacturing Facilities: Managing safety protocols on production lines, especially where human interaction with machinery is frequent.

-

Chemical Processing Plants: Controlling access to hazardous areas and ensuring safe operation of chemical processing equipment.

-

Power Generation Plants: Monitoring and controlling safety mechanisms in turbines and generators, ensuring operational safety.

-

Oil & Gas Industry: Enhancing safety measures on drilling rigs and refineries by controlling access to dangerous zones.

-

Pharmaceutical Manufacturing: Ensuring compliance with safety standards in environments requiring strict contamination control.

-

Transportation Systems: Managing safety protocols in automated transit systems, including door control and emergency response mechanisms.

Advantages

-

SIL 3 Certification: Meets high safety integrity level requirements, ensuring reliable performance in critical applications.

-

High Processing Speed: Operates at 100 kHz, allowing for rapid response to safety events.

-

Multiple Input/Output Channels: Equipped with 16 digital inputs and 8 digital outputs, providing flexibility in various applications.

-

Robust Communication: Utilizes PROFIBUS DP protocol for seamless integration into existing control systems.

-

Compact and Durable Design: Its compact size and durable housing make it suitable for installation in space-constrained and harsh environments.

-

Energy Efficient: Low power consumption (500 mA at 24V DC) contributes to overall energy savings in industrial operations.

-

Easy Integration: Designed for DIN rail mounting, facilitating straightforward installation and maintenance.

-

Enhanced Safety Features: Specifically engineered to manage door control mechanisms, reducing the risk of unauthorized access and ensuring personnel safety.

Recent News & Updates

-

“HIMA F4107 Enhances Safety in Automotive Manufacturing Plants”: A leading automotive manufacturer has integrated the F4107 module to improve safety protocols on their assembly lines.

-

“Chemical Industry Adopts HIMA F4107 for Hazardous Area Access Control”: Chemical processing facilities are implementing the F4107 to manage access to high-risk zones, ensuring compliance with safety regulations.

-

“Power Plants Upgrade to HIMA F4107 for Improved Turbine Safety”: Several power generation facilities have adopted the F4107 module to enhance the safety of turbine operations.

-

“HIMA F4107 Receives Industry Award for Excellence in Safety Engineering”: The module has been recognized for its innovative design and contribution to industrial safety standards.

Frequently Asked Questions (FAQ)

1. What is the primary function of the HIMA F4107 Safety-Related and Door Module?

The HIMA F4107 is designed to provide advanced safety functions in industrial automation systems. Its primary function is to manage safety protocols, including door control mechanisms, ensuring that equipment and personnel are protected during operations. It acts as a critical component in safety-critical environments, allowing for controlled access and emergency shutdowns. This module provides peace of mind by preventing unauthorized access to hazardous areas.

2. Is the HIMA F4107 module certified for safety-critical applications?

Yes, the HIMA F4107 is certified with SIL 3 (Safety Integrity Level 3), which is the highest level of safety certification for industrial equipment. This certification ensures the module meets the stringent requirements for safety-critical applications in various industries, including chemical processing, power generation, and manufacturing.

3. What are the communication protocols supported by the HIMA F4107?

The HIMA F4107 supports the PROFIBUS DP communication protocol, which allows it to be easily integrated into existing control systems. PROFIBUS DP is widely used in industrial automation due to its reliability and high-speed communication capabilities. This ensures that the F4107 can exchange data with PLCs (Programmable Logic Controllers) and other systems seamlessly.

4. How does the HIMA F4107 module contribute to industrial safety?

The F4107 module plays a crucial role in maintaining operational safety by providing a controlled environment for both equipment and human interaction. It ensures that safety barriers, door access systems, and emergency stop mechanisms are in place and functional, thereby minimizing the risk of accidents. The module’s ability to monitor and control access points to dangerous zones reduces the chances of human error and equipment failure.

5. What is the input voltage and power consumption of the F4107?

The HIMA F4107 operates with a 24V DC input voltage. Its current consumption is approximately 500 mA. This low power consumption helps reduce the overall energy costs of running industrial safety systems. Its efficiency in power usage makes it an ideal choice for energy-conscious applications.

6. What is the operating temperature range of the HIMA F4107 module?

The HIMA F4107 can operate in a wide range of temperatures, specifically between -20°C and +60°C. This broad temperature range ensures that the module can function effectively in various environmental conditions, from cold climates to high-temperature industrial settings. It is ideal for both indoor and outdoor installations.

7. Can the HIMA F4107 be integrated with other safety systems?

Yes, the HIMA F4107 is designed for seamless integration with other safety-related modules and systems. Its DIN rail mounting and PROFIBUS DP communication make it compatible with most existing industrial automation systems. This makes it an easy-to-integrate solution for enhancing safety measures in legacy systems as well as new installations.

8. How does the HIMA F4107 module handle door control and safety functions?

The F4107 module is equipped with specialized features for controlling access to hazardous areas. It monitors door positions and ensures that doors are only opened when it is safe to do so. Additionally, it handles safety protocols such as emergency stops and safety interlocks, preventing unauthorized access and protecting operators from dangerous machinery or environments.

9. What are the dimensions and weight of the HIMA F4107?

The HIMA F4107 module has compact dimensions of 120 x 80 x 40 mm, making it easy to mount in space-constrained areas. The module weighs only 0.25 kg, which contributes to its lightweight design and ease of installation. Its compact size makes it a versatile option for various industrial control systems where space efficiency is important.

10. In what industries is the HIMA F4107 used?

The HIMA F4107 module is designed for use in a variety of industries where safety is critical. These include:

-

Chemical and Petrochemical Industries: Ensures safe operation of machinery and controls access to hazardous areas.

-

Power Generation: Manages safety protocols for turbines, generators, and other high-risk equipment.

-

Manufacturing: Controls access to production lines and provides emergency stop functions.

-

Oil & Gas: Monitors safety in drilling rigs and refineries.

-

Pharmaceuticals: Ensures strict access control in cleanroom environments.

-

Transportation: Used for controlling safety features in automated transit systems.

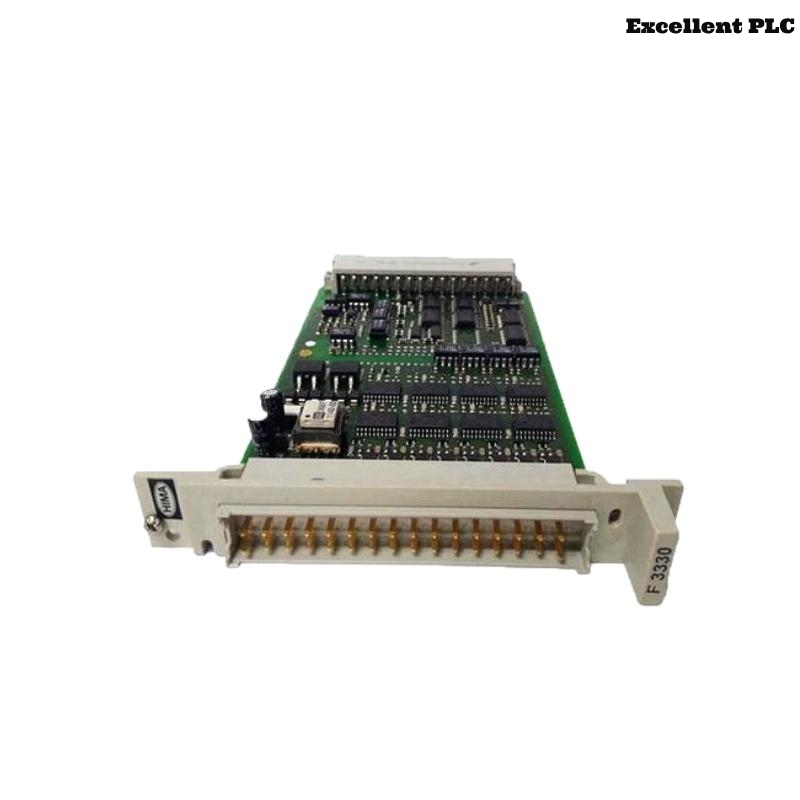

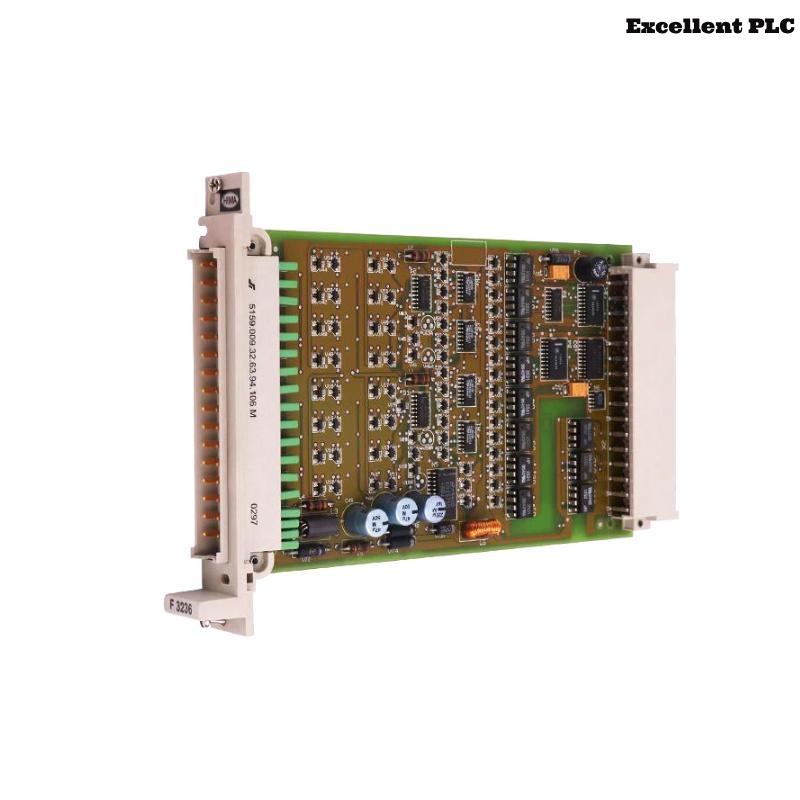

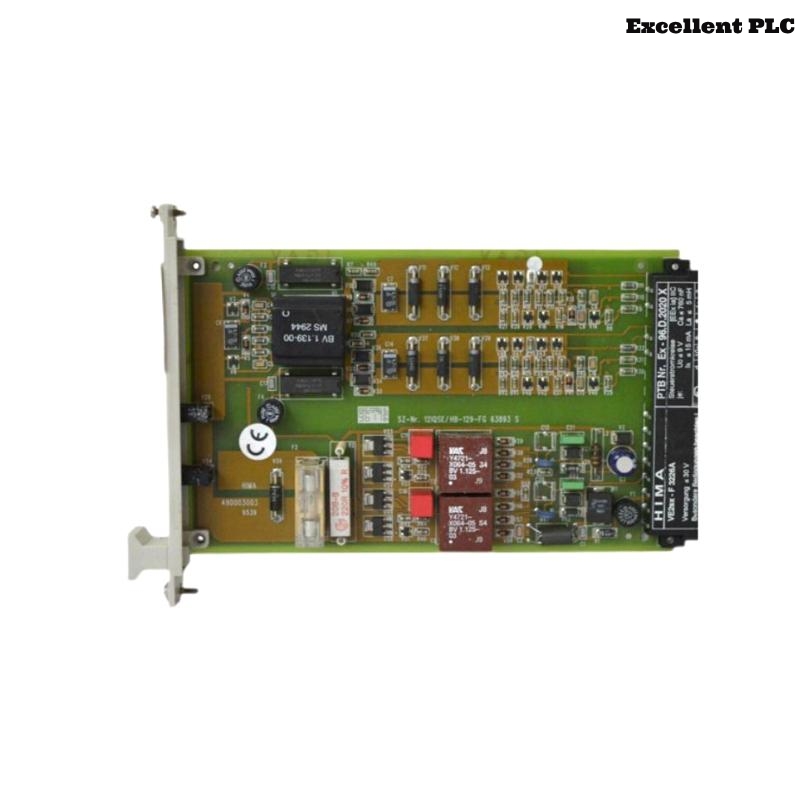

Recommended Related Models

Model Description Application HIMA F4108 Digital Input Module Used for safety-critical I/O HIMA F4207 Safety Logic Processor Module Advanced safety control module HIMA F4112 High-Integrity Communication Module Communication for safety systems HIMA F4120 Safe Monitoring Module Monitors critical machine states HIMA F4135 Emergency Shutdown Module Emergency stop systems HIMA F4150 Safety Interlock Module Machine access safety controls HIMA F4167 Safety Exit Monitoring Module Exit control in hazardous zones HIMA F4170 Digital Output Safety Module Safety output control Popular HIMA Models

Model Description Application HIMA F7130 Safety PLC Used for SIL 3 safety systems HIMA F7120 Process Safety System Safety monitoring in process industries HIMA F3110 Fieldbus Safety Interface Fieldbus communication for safety HIMA F3410 Safety I/O Module Input/output safety modules HIMA F5300 Safety Field Controller Remote safety control HIMA F3000 SIL-3 Safety Module High-integrity safety systems HIMA F8000 Redundant Safety System Dual-redundant safety control HIMA F9000 Advanced Safety Monitoring Module Monitoring critical safety events -

Excellent PLC

Excellent PLC