| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666084105 | |||||||

| +8613666084105 | ||||||||

| 13666084105 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

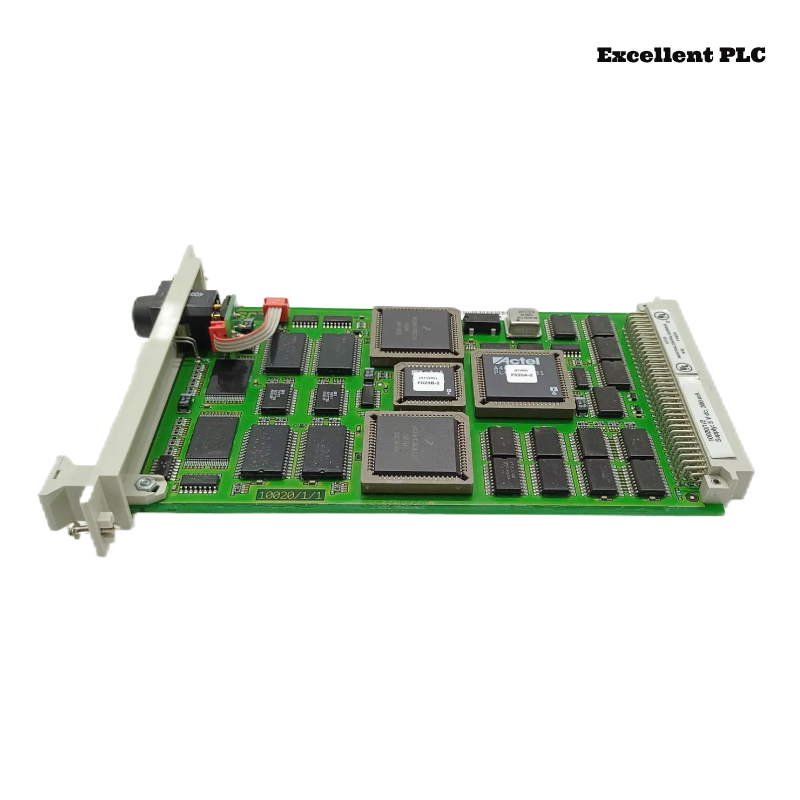

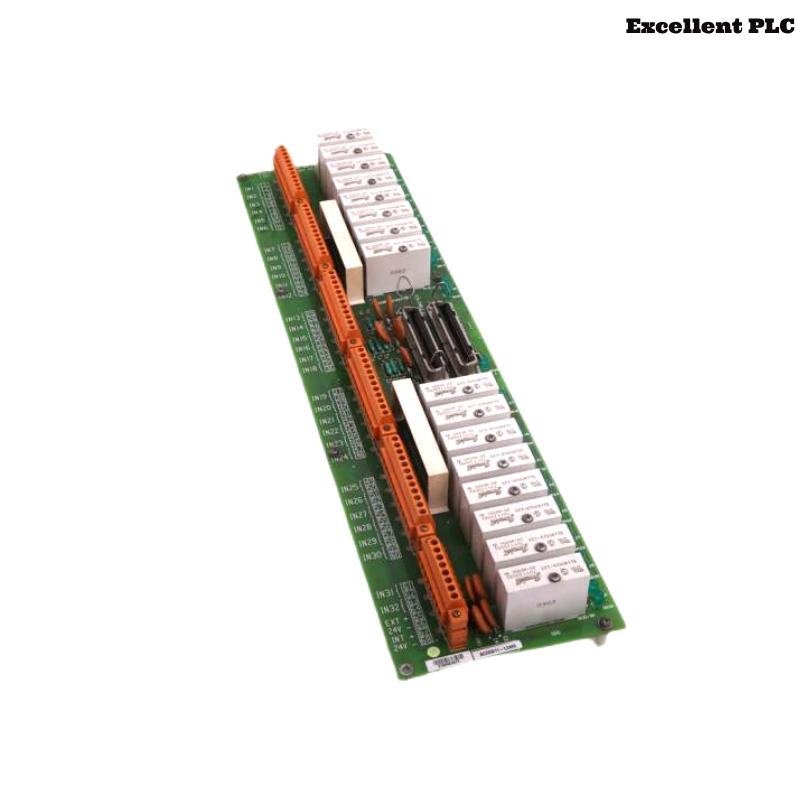

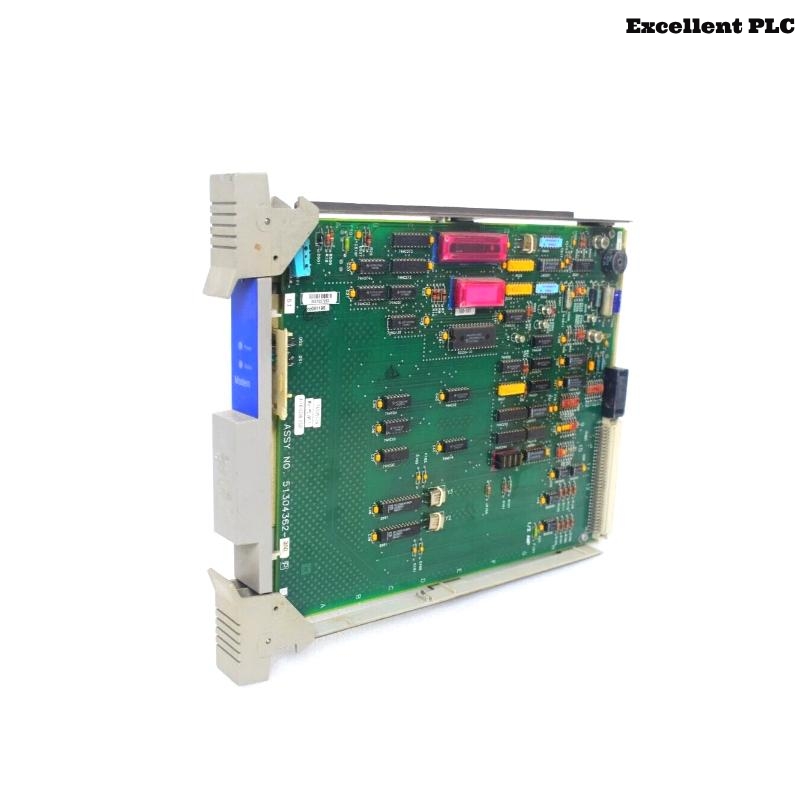

The Honeywell 10020/1/2 FSC CPU Module is a central processing unit designed for Honeywell’s Fail Safe Controller (FSC) systems. It ensures high reliability and safety in industrial automation applications, making it suitable for industries such as oil and gas, chemical processing, power generation, and manufacturing. The module’s robust design and advanced features contribute to the overall efficiency and safety of critical control processes.

Product Specifications

| Specification | Details |

|---|---|

| Product Number | 10020/1/2 |

| Product Type | FSC CPU Module |

| Processor | Quad Processor Module |

| Memory | – 128 Kbytes of RAM for system and application variables – Additional 128 Kbytes of RAM for application use |

| Dimensions | 120 × 80 × 40 mm |

| Weight | 0.14 kg |

| Power Requirements | 5 V DC, 300 mA |

| Operating Temperature | -20°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95% non-condensing |

Applications

The 10020/1/2 FSC CPU Module is utilized in various industrial applications, including:

- Process Automation: Managing and controlling complex industrial processes to ensure operational efficiency and safety.

- Safety Systems: Implementing fail-safe mechanisms to prevent accidents and ensure compliance with safety standards.

- Manufacturing Control: Overseeing machinery and production lines to maintain product quality and consistency.

- Energy Management: Monitoring and controlling energy production and distribution systems for optimal performance.

Advantages

The Honeywell 10020/1/2 FSC CPU Module offers several advantages:

- High Reliability: Designed for critical applications requiring continuous operation and minimal downtime.

- Enhanced Safety: Incorporates fail-safe features to maintain safe operations under various conditions.

- Scalability: Easily integrates into existing systems, allowing for future expansion and upgrades.

- Robust Performance: Capable of handling complex control tasks with high processing power and memory capacity.

Frequently Asked Questions (FAQ)

1. What is the primary function of the Honeywell 10020/1/2 FSC CPU Module?

The module serves as the central processing unit in Honeywell’s Fail Safe Controller systems, managing control logic, processing input signals, and executing safety functions to ensure reliable industrial automation.

2. How many processors does the 10020/1/2 module have?

It features a quad-processor configuration, allowing for parallel processing and enhanced performance in critical applications.

3. What type of memory is included in the module?

The module includes 128 Kbytes of RAM for system and application variables, with an additional 128 Kbytes available for application use.

4. What are the dimensions and weight of the module?

The module measures 120 × 80 × 40 mm, with a weight of 0.14 kg.

5. What power requirements does the module have?

It operates on a 5 V DC power supply, consuming approximately 300 mA.

6. Is the 10020/1/2 module suitable for harsh industrial environments?

Yes, it is designed to operate within a temperature range of -20°C to +60°C and can withstand humidity levels from 5% to 95% non-condensing, making it suitable for various industrial settings.

7. Can the module be integrated into existing FSC systems?

Yes, the 10020/1/2 module is designed for seamless integration into Honeywell’s FSC systems, supporting scalability and compatibility with existing infrastructure.

8. What safety features are incorporated in the module?

The module includes fail-safe mechanisms and redundancy to ensure continuous operation and adherence to safety protocols in critical applications.

9. How does the quad-processor configuration benefit industrial applications?

The quad-processor setup allows for parallel processing of tasks, enhancing the system’s ability to handle complex control functions and improving overall efficiency.

10. Can the module be used in redundant configurations for increased reliability?

Yes, the Honeywell 10020/1/2 module supports redundant configurations, allowing for a backup CPU module to take over in the event of a failure. This redundancy enhances system reliability and ensures continuous operation in safety-critical applications.

Recommended Related Models

| Model Number | Description | Features |

|---|---|---|

| 10020/1/1 | FSC CPU Module | Dual-processor, 128 KB RAM |

| 10020/1/3 | FSC CPU Module with Enhanced Memory | Quad-processor, 256 KB RAM |

| 10020/2/1 | FSC Redundant CPU Module | Dual-processor, redundancy support |

| 10020/2/2 | FSC High-Performance CPU Module | Quad-processor, enhanced processing speed |

| 10020/3/1 | FSC Compact CPU Module | Compact design, dual-processor |

| 10020/3/2 | FSC Compact High-Performance CPU Module | Compact design, quad-processor |

| 10020/4/1 | FSC CPU Module with Extended I/O Support | Quad-processor, extended I/O capabilities |

| 10020/4/2 | FSC CPU Module with Advanced Networking | Enhanced communication capabilities |

| 10018/E/1 | FSC Ethernet Module | High-speed Ethernet communication |

| 10018/2/U | FSC Communication Module | Supports various industrial protocols |

Popular Honeywell Models:

| Model Number | Description | Features |

|---|---|---|

| C300 | Universal Process Controller | High-performance, advanced process control |

| UMC800 | Universal Multi-Loop Controller | Multi-loop control, customizable displays |

| Experion PKS | Process Knowledge System | Distributed control, enterprise integration |

| HC900 | Hybrid Control System | Modular design, batch processing support |

| TDC 3000 | Distributed Control System | Legacy Honeywell DCS, robust control |

| 10105/2/1 | FSC I/O Module | High-speed input/output processing |

| 10106/2/1 | FSC Power Supply Module | Redundant power supply system |

| 10107/2/1 | FSC Field Termination Unit | Interface for field devices |

| 51405099-100 | I/O Link Module | High-speed data transfer capabilities |

| 51401496-100 | Control Processor Module | Advanced control processing |

Excellent PLC

Excellent PLC